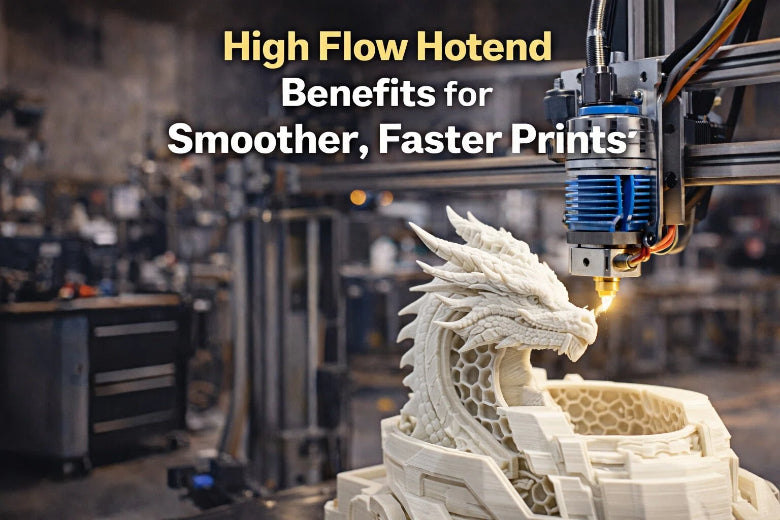

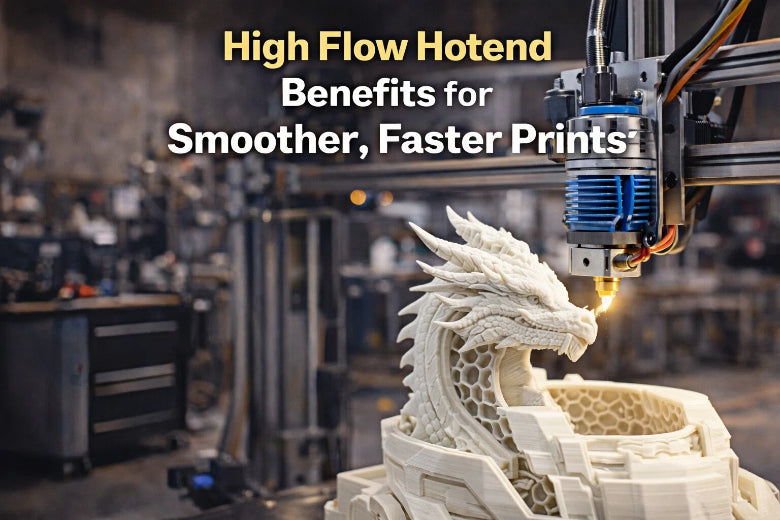

A high-flow hotend offers several high flow hotend benefits, allowing you to print faster while maintaining excellent quality. Here are some key high flow hotend benefits and upgrades:

|

Feature |

Description |

|---|---|

|

Prevents plastic from sticking, so your prints don’t fail or look messy—one of the high flow hotend benefits. |

|

|

Nozzle Durability |

ObXidian™ technology makes the nozzle last much longer than standard steel, adding to the high flow hotend benefits. |

|

Increased Flow Rate |

Internal improvements let you print up to 70% faster with a consistent flow, showcasing more high flow hotend benefits. |

Additional high flow hotend benefits include:

- Heats up more quickly thanks to a copper alloy construction

- Smoother filament movement for improved detail and finish

- High-flow nozzle is ideal for large prints

Consider your specific printing needs to decide if these high flow hotend benefits are right for you.

Key Takeaways

High-flow hotends can make printing up to 70% faster. You can finish big projects in less time. These hotends help prints stick together better. They also make surfaces smoother. Your models will look more professional. High-flow hotends work with many materials. You can use basic filaments or strong engineering plastics. This gives you more choices for your projects. Upgrading to a high-flow hotend lowers the chance of clogs. It also stops jams from happening. Printing becomes more reliable with fewer stops. Changing your slicer settings is very important. This helps you get the most from a high-flow hotend. It makes sure your prints look and work their best.

What Is a High-Flow Hotend?

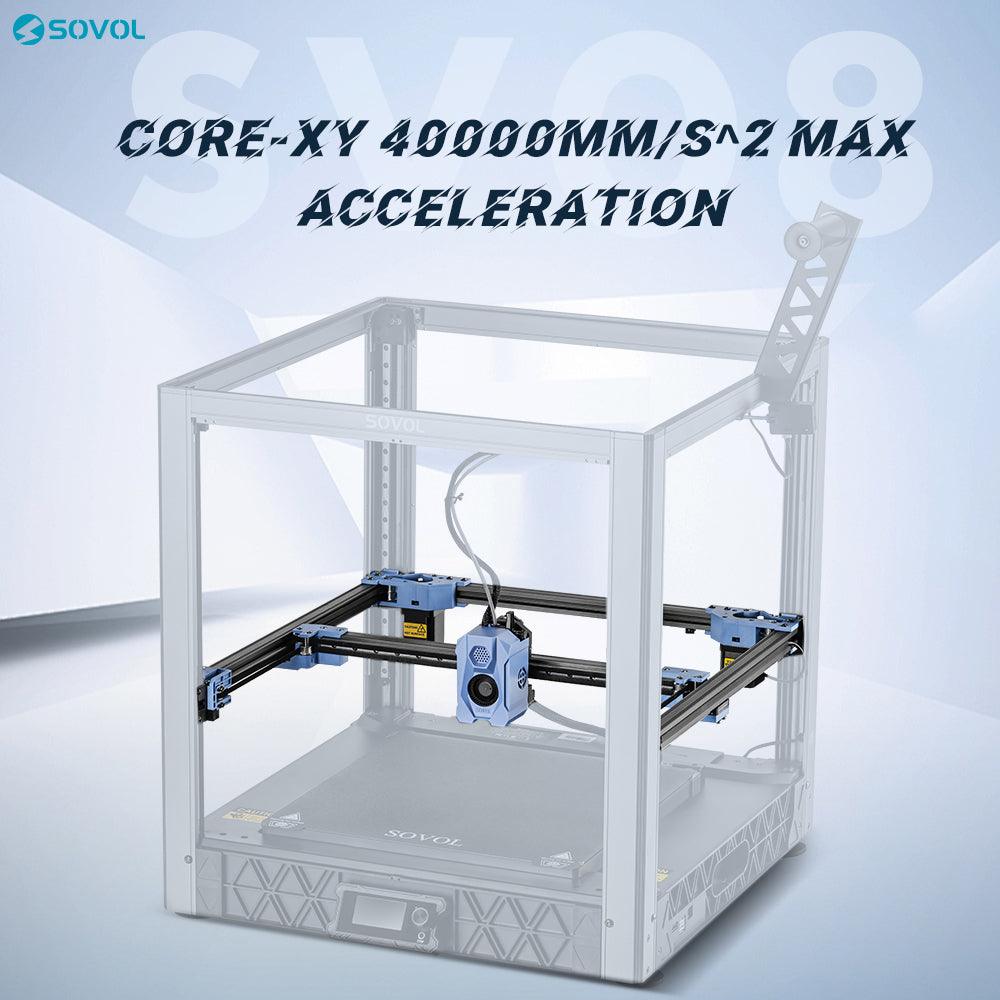

Key Features and Design

A high-flow hotend is a special part for your 3D printer. It helps you print faster and get better results. High flow hotends have a longer melt zone. This lets the filament heat up and melt for a longer time before coming out of the nozzle. The design makes it easier to print bigger parts or use materials that need more heat. Many high-flow hotends use strong materials and special coatings. These help them handle more heat and faster printing.

Tip: If you want to make big models or use tough materials, a high-flow hotend can help your prints look smoother and work better.

Here is a quick way to see how a high-flow hotend is different from a standard hotend:

|

Specification |

High-Flow Hotend |

Standard Hotend |

|---|---|---|

|

Print Speed Improvement |

Up to 30% faster |

Standard speeds |

|

Material Compatibility |

Optimized for high flow materials (like PLA Basic, Bambu ASA) |

General compatibility |

|

Layer Adhesion |

Improved for stronger parts |

Standard adhesion |

|

Speed Modes |

Sport and Ludicrous modes available |

Not applicable |

Differences from Standard Hotends

There are some clear differences between high flow hotends and standard hotends. High flow hotends can move more filament through the nozzle at one time. The longer melt zone melts the filament faster. This means you can print faster without losing quality. Standard hotends are good for most simple prints. But they might have trouble with big models or special materials. High flow hotends give you more choices and better results when you want to do more with your printer.

How a High-Flow Hotend Works

Enhanced Thermal Performance

You want your 3D printer to make strong parts and work well. The high-flow hotend helps by moving heat better through the nozzle. It uses special metals and has a longer melt zone. This means the filament heats up faster and more evenly. When the filament gets even heat, it melts at the right speed. The melted filament sticks together better. This gives you strong layers and fewer problems with underextrusion.

The high-flow hotend lets more filament move because of how heat and pressure work together. When you print slowly, the filament stays in the melt zone longer. This helps the heat spread better and lowers the pressure as the temperature goes up. If you print fast, the filament does not get as hot. This means the pressure does not drop as much. Knowing this helps people design better nozzles, like the Bondtech CHT and E3D Revo High-Flow. These nozzles move heat better by making more contact between the nozzle and filament.

You can see the good things about better thermal performance in many ways:

- The filament heats evenly, so layers stick well.

- High-flow hotends spread heat better, even when you print fast.

- If the heat is not even, you can get underextrusion and weak prints.

Faster and Stable Extrusion

You want your printer to move filament fast without jams or rough spots. The high-flow hotend helps with this. The bigger melt zone and better heat transfer let you push more filament through the nozzle quickly. You get steady extrusion, so each layer is smooth. This helps you print big models or use high-infill settings without slowing down.

When you use a high-flow hotend, you get fewer clogs and more reliable prints. The nozzle design keeps the filament moving, even with tough materials. You can print faster and still get clean, strong results. This upgrade lets you try new projects and materials.

High Flow Hotend Benefits

Increased Print Speed

You want your fast 3d printer to finish jobs quickly without losing detail. High flow hotend benefits include a much higher print speed. The special design of a high-flow hotend lets you push more melted filament through the nozzle at once. This means you can print bigger parts or more complex shapes in less time. The longer melt zone and larger heater cartridge keep the filament hot and ready, so you do not have to slow down.

Take a look at how much faster a high-flow hotend can work compared to a standard one:

|

Hotend Type |

Flow Rate (mm³/s) |

Printing Speed (mm/s) |

Speed Increase Factor |

|---|---|---|---|

|

High-Flow |

Up to 52 |

~600 |

3 to 5 times faster |

|

Standard |

10 to 15 |

Varies |

- |

With a high-flow hotend, you can achieve up to five times the print speed of a regular setup. This makes your fast 3d printer even more powerful. You do not have to wait as long for large models or high-infill prints. You get more done in less time, which is one of the most important high flow hotend benefits.

Improved Surface Quality

You care about how your prints look and feel. High flow hotend benefits include better print quality, especially on the surface of your models. When you use a high-flow hotend, the filament melts evenly and flows smoothly. This gives you clean lines and fewer rough spots. The improved thermal performance means each layer sticks well to the one below it.

Here are some ways a high-flow hotend can improve print quality:

- You get better results with the same filament, so you do not need special materials.

- Layer adhesion increases, making your prints stronger and smoother.

- The surface of your models looks more consistent and professional.

A fast 3d printer with a high-flow hotend can keep up the speed without making the print quality worse. You see fewer blobs or gaps, and your finished parts look great.

Reliability and Fewer Clogs

You want your printer to work every time you start a job. High flow hotend benefits include more reliable printing and fewer clogs. The larger melt zone and better heat control keep the filament moving. This means you do not have to stop and fix jams as often. The special coatings on many high-flow hotends also help prevent plastic from sticking inside the nozzle.

Check out how different high-flow hotends perform at high temperatures:

|

Hotend |

Flow Rate at 280°C |

|

|---|---|---|

|

Copperhead® |

31 mm³/s |

33 mm³/s |

|

Mosquito® |

31 mm³/s |

35 mm³/s |

|

Mosquito® Magnum |

34 mm³/s |

40 mm³/s |

These numbers show that a high-flow hotend can keep up with fast 3d printer speeds, even at higher temperatures. You get steady extrusion, which means fewer problems and more successful prints. This reliability is a key part of high flow hotend benefits.

Material Versatility

You may want to try different types of filament for your projects. High flow hotend benefits include the ability to handle a wide range of materials. The improved thermal performance lets you print with basic filaments like PLA, but also with tougher engineering plastics. You can switch between materials without worrying about jams or poor print quality.

A high-flow hotend can melt and push out more types of filament because it heats them evenly. This means you can use your fast 3d printer for many different jobs, from simple models to strong, functional parts. You get more options and better results, no matter what you want to print.

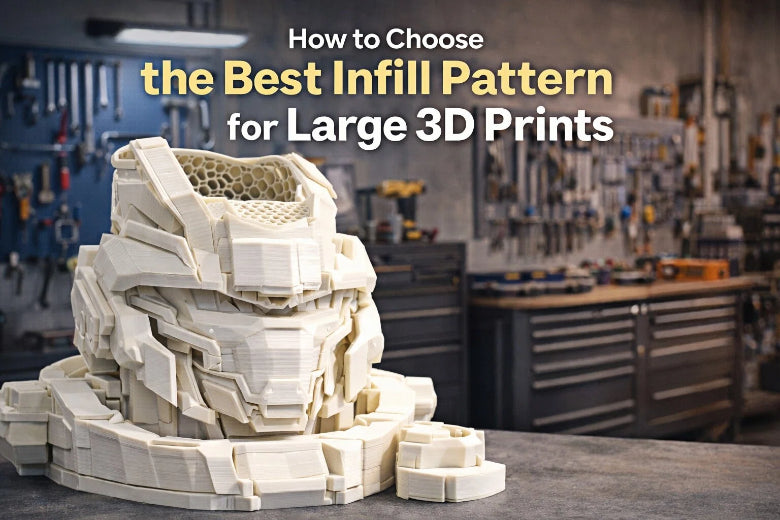

Large and High-Infill Prints

You might want to print big models or parts that need to be very strong. High flow hotend benefits shine when you work on large prints or use high infill settings. The high-flow hotend can move more plastic at once, so you do not have to slow down for bigger jobs. The special coatings and better heat control keep the extrusion steady, even during long prints.

Here is how a high-flow hotend helps with large and high-infill prints:

|

Feature |

Description |

|---|---|

|

Volumetric Flow Rate Increase |

Up to 70% increase in volumetric flow rate for more reliable and consistent extrusion. |

|

Non-Stick Coating |

Helps prevent plastic buildup, crucial for consistent extrusion during large model printing. |

- You see better visual consistency across the whole model.

- Stronger parts come from enhanced flow and better layer bonding.

A fast 3d printer with a high-flow hotend can handle big projects without losing print quality. You spend less time waiting and get more reliable results. These high flow hotend benefits make your printer ready for any challenge.

Practical Considerations and Limitations

Slicer Profile Adjustments

To get the best results from your high-flow hotend, you need to adjust your slicer settings. These changes help you reach the highest print quality and avoid common problems. Here is a table with important slicer adjustments:

|

Adjustment Type |

Description |

|---|---|

|

E-steps Calibration |

Makes sure your printer pushes out the right amount of filament for accurate flow. |

|

Flow Rate Calibration |

Controls how much filament comes out, which affects print quality and part accuracy. |

|

Max Volumetric Speed |

Sets the top speed for your hotend, so you do not get under or over-extrusion at high speeds. |

You should check these settings before starting a new print. This helps you keep print quality high and avoid wasted material.

Oozing and Retraction Challenges

When you use a high-flow hotend, you may notice more oozing or stringing. These issues can lower print quality if you do not fix them. Here are some common causes and solutions:

- Filament has absorbed moisture.

- Printing temperature is too high.

- Retraction settings are not correct.

- Nozzle is clogged or dirty.

- Travel moves are too slow.

To improve print quality, try these tips:

- Dry your filament or use a new spool.

- Lower the print temperature by 5-10 degrees.

- Increase retraction distance and speed.

- Raise travel speed if your printer allows.

- Clean or replace your nozzle if needed.

When a High-Flow Hotend Is Not Needed

You do not always need a high-flow hotend for every project. If you care most about print quality and fine details, a standard hotend with a smaller nozzle may work better. For small models or parts that need sharp edges, you may not see much benefit from upgrading. The time saved by switching nozzles can also be small compared to the effort.

Common Misconceptions

Some people think high-flow hotends only give a small boost in speed or that the heater is the main limit. In fact, high-flow hotends can double your flow rate when set up right. The heater usually works well if you use a silicone sock and follow best practices. Most problems come from slicer settings or oozing, not from melting filament too slowly.

|

Misconception |

Actual Performance Data |

|---|---|

|

Flow increase over ordinary nozzles is small |

High-flow hotends can reach about 2x the flow rate of standard ones. |

|

Heater power is the main limiting factor |

Heater is not usually the limit if you use a sock and tune settings. |

You can get great print quality with the right setup and a little tuning.

Real-World Experiences

User Testimonials

You can learn a lot from people who use high-flow hotends every day. Many people talk about their experiences online. They share both the good and bad things. Here is a simple list of what users say:

|

Benefit/Drawback |

Description |

|---|---|

|

Improved Print Quality |

You can get print quality as good or better than with standard hotends. |

|

Faster Nozzle Changes |

You can change nozzles quickly, which helps if you switch sizes a lot. |

|

Higher Flow Rates |

You can print faster, but you may need a better heater for the best results. |

|

Higher Costs |

High-flow hotends usually cost more than regular ones. |

|

Need for Better Heaters |

You might need to buy a stronger heater to get the most from your new hotend. |

|

Issues with Third-Party Nozzles |

You could have problems if you use nozzles from other brands, which might change how well it works. |

Note: Many people say high-flow hotends help them finish big prints faster and with fewer jams. But you should be ready for extra costs and check if your printer works with the new parts before you upgrade.

Example Print Improvements

You can see how a high-flow hotend changes real prints. For example, people who print big models or use high infill settings often see smoother surfaces and stronger layers. One user compared prints from a regular hotend and a high-flow model. The high-flow hotend kept the temperature steady, so there was less under-extrusion and the print looked better. When using a regular hotend at high speeds, the print had almost 40% under-extrusion, which made weak spots.

You may still have some problems. Some people say that prints at high speeds can look uneven, with shiny or dull spots. Parts can also be weaker if you print too fast. Some users find it harder to change nozzles or get the best results with parts from other brands.

Common problems after upgrading:

- Uneven surface finish at high speeds

- Weaker parts when printing too fast

- Harder to change nozzles with some setups

You can get the best results by changing your settings and knowing what your printer can do. High-flow hotends are great for big, strong prints, but you should balance speed and quality for the best results.

You can print faster and get smoother results with a high-flow hotend. This is most helpful when you make big models or need to finish projects quickly. Think about these things before you upgrade:

- Each filament type reacts to heat in its own way.

- Good cooling and the right retraction settings help your prints look better.

- High-flow hotends might cause more oozing and need extra tuning.

Pros:

- You can change nozzles quickly for more options.

- You get higher flow rates, so printing is faster.

Cons:

- Some models do not have very high flow rates.

- Oozing can be harder to fix.

If you want your printer to be faster and more reliable, upgrade your hardware and pick the right materials. High-flow hotends are great for people who print large or fast. If you mostly print small, detailed parts, a standard hotend might be better for you.

FAQ

What is the main advantage of a high-flow hotend?

You can print faster and make larger models. The high-flow hotend melts and pushes more filament through the nozzle. This helps you finish projects quickly and get smoother results.

Do I need to change my slicer settings for a high-flow hotend?

Yes, you should adjust your slicer settings. You need to set the correct flow rate and retraction values. This helps you avoid oozing and keeps your prints looking clean.

Can I use any filament with a high-flow hotend?

You can use most common filaments, like PLA, PETG, and ABS. High-flow hotends also handle tough materials better. Always check the temperature range for your filament and hotend.

Will a high-flow hotend improve print quality for small models?

You may not see much improvement on small, detailed prints. High-flow hotends work best for large models or high-infill parts. For tiny details, a standard hotend often gives better results.

How do I prevent clogs with a high-flow hotend?

Keep your nozzle clean and use dry filament. Set the right temperature for your material. Regular maintenance helps you avoid jams and keeps your printer running smoothly.