Large-size printers let you make things that seemed impossible before. You can use these printers to build furniture, boats, or houses. Many makers pick large-size printers because they finish big projects faster. These printers also help you waste less material. You can make more custom products and print hard shapes at once. These printers help you save money by using fewer materials. They also cut down on the need for people to work by hand. Think about what you could make if you had fewer limits.

Key Takeaways

Large-size 3D printers help you make big, strong things. You can also make detailed objects in one piece. This saves you time and hard work. These printers use new materials and smart technology. This gives you more ways to design and build hard shapes. Large-scale 3D printing makes things faster. It uses less material and costs less than old ways. Many industries and makers use large 3D printers for many projects. They make things like furniture, art, medical tools, and building parts. Large 3D printers can cost a lot. They also need space and special skills. But new technology and makerspaces help more people use them.

Large-Size Printers Explained

What Makes Them Different

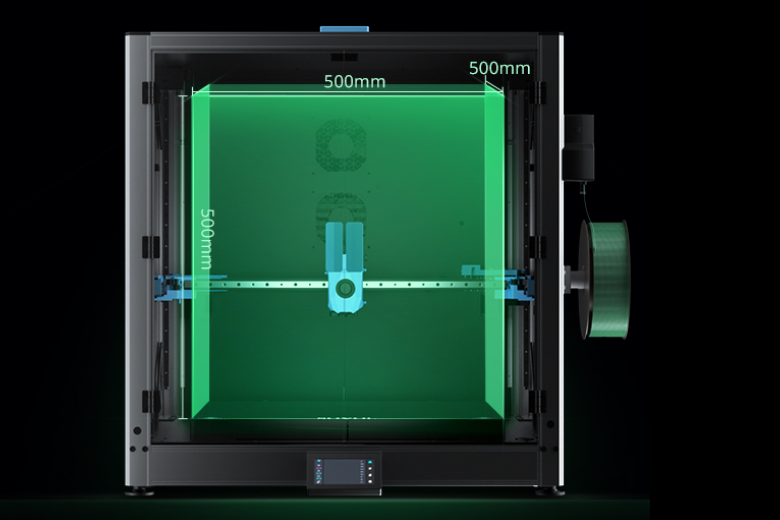

You may ask how large 3d printers are not like desktop ones. The biggest change is their size and how strong they are. Large-size printers can make much bigger things in one go. You do not have to break your design into small pieces. This saves time and keeps your project strong.

- Large 3d printers let you print big, tricky shapes in one piece.

- These printers use special materials like PAEK, PEEK, ULTEM™, and carbon fiber.

- They have heated build chambers to keep the temperature steady. This helps your prints stay tough and correct.

- You can try many printing types, like FDM, SLA, SLS, and others.

- Desktop printers are smaller and cannot use tough materials or high heat.

Here is a simple chart to compare:

|

Aspect |

Large-Size (Industrial) 3D Printers |

Conventional (Desktop) 3D Printers |

|---|---|---|

|

Build Volume |

Very large, up to 36 x 24 x 36 in |

Small, fits on a desk |

|

Supported Materials |

Advanced thermoplastics, composites |

Basic plastics like PLA, ABS |

|

Build Chamber |

Heated and controlled |

Often not heated |

|

Material Properties |

High heat, chemical, and impact resistance |

Less robust, good for prototypes |

|

Printing Technologies |

Many types (FDM, SLA, SLS, etc.) |

Mostly FDM or SLA |

Tip: If you want to make strong, big, or detailed things, large-size printers give you more choices and better results.

Who Uses Large 3D Printers

You can find large 3d printers in many jobs and maker spaces. These printers help people who need big, special, or tricky parts.

- Aerospace engineers use large 3d printers for rocket parts and satellite brackets.

- Car makers print custom tools and parts to work faster.

- Doctors and hospitals make custom prosthetics and surgery tools.

- Builders and architects print houses, models, and molds for building.

- Artists and studios use these printers for fast design and cool art.

- Shipbuilders and defense teams print big valves and tricky parts for ships and planes.

- Manufacturers use large-size printers to make machine parts and waste less.

Hobbyists also use large 3d printers for cosplay props, big models, and fun projects. Professionals pick these printers for medical, car, and food-safe parts. You can print with special materials or just use PLA and ABS, based on what you need.

Large-size printers give you new ways to make things, whether you are a student, artist, engineer, or hobbyist. You get more freedom, better materials, and bigger results.

Creative Power of Large 3D Printers

Bigger Builds, Fewer Limits

Large-scale 3d printing lets you make things that were once too hard. You can print tiny chess pieces or huge house walls. This technology removes the size limits of regular 3d printers. Imagine building a real dinosaur skeleton for a museum. Naturalis B.V. did this with two large 3d printers. They made a 12-meter-long Tyrannosaurus rex replica. They printed over 300 bones. Each bone was strong and had lots of detail. This shows how large-scale 3d printing makes big projects possible.

You can see this creative power in many areas: 1. Builders in Texas use large 3d printers to make homes fast. They print walls for 400-square-foot houses with concrete-like materials. 2. Artists in Italy made "The Whale Pass," a 5-meter-tall whale head, by printing big metal pieces. 3. In North Carolina, a 17-foot-high sculpture called "Purple S.T.E.A.M." was printed using carbon and ABS filament. 4. Brand designers made a giant snow globe with a 3d printed Mickey Mouse steamboat inside. 5. NASA printed a 1,700-square-foot Mars habitat to test living on other planets.

Note: Large 3d printers let you print big, strong, and detailed objects all at once. You do not have to split your design into small parts.

Large-scale 3d printing also gives you more freedom to design. You can print furniture, art, or even whole buildings. Old ways of making things often limit your project’s size because of molds and tools. With large 3d printers, you skip those limits and print what you dream up.

Here is a quick look at how large-scale 3d printing compares to traditional methods:

|

Aspect |

Large-Scale 3D Printing |

Traditional Manufacturing |

|---|---|---|

|

Build Volume |

Up to 100 feet long (e.g., BAAM systems) |

Limited by molds and tools |

|

Design Flexibility |

High; complex shapes and unibody parts |

Limited; complex shapes are costly |

|

Assembly Needs |

Low; print in one piece |

High; many parts need assembly |

|

Material Waste |

Low; additive process |

High; subtractive process |

You can see that large-scale 3d printing gives you more choices and fewer limits. You get to try new ideas and make bigger things without extra steps.

Complex Parts, Single Prints

Large 3d printers change how you work on hard projects. You do not need to print many small pieces and glue them together. You can print a whole part, even if it has tricky shapes inside. This saves you time and helps you make fewer mistakes.

For example, in tissue engineering, small 3d printers make you print tiny blocks and put them together to make a big organ. This takes a lot of time and can cause errors. Large-scale 3d printing lets you print the whole organ at once. You get a stronger and more accurate result.

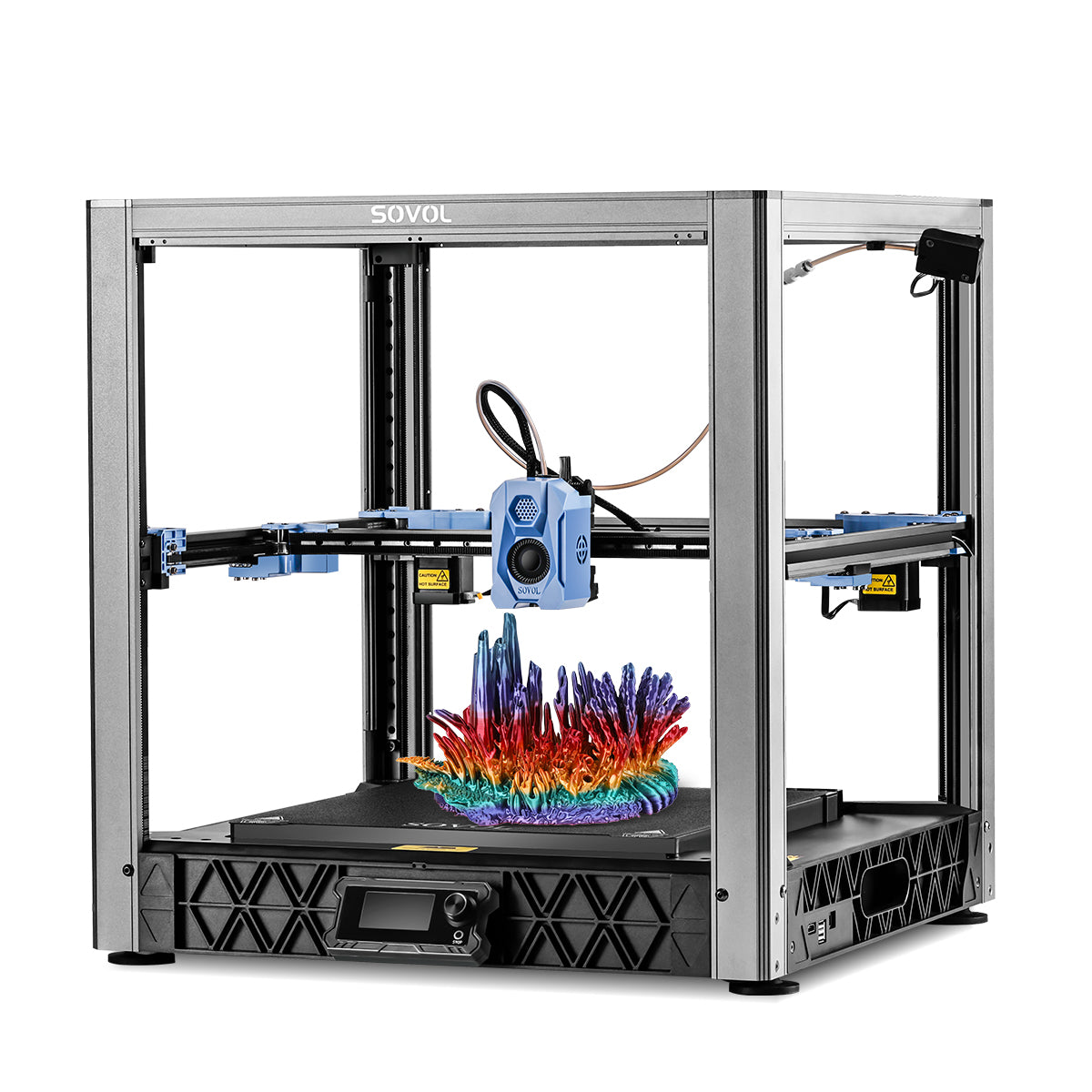

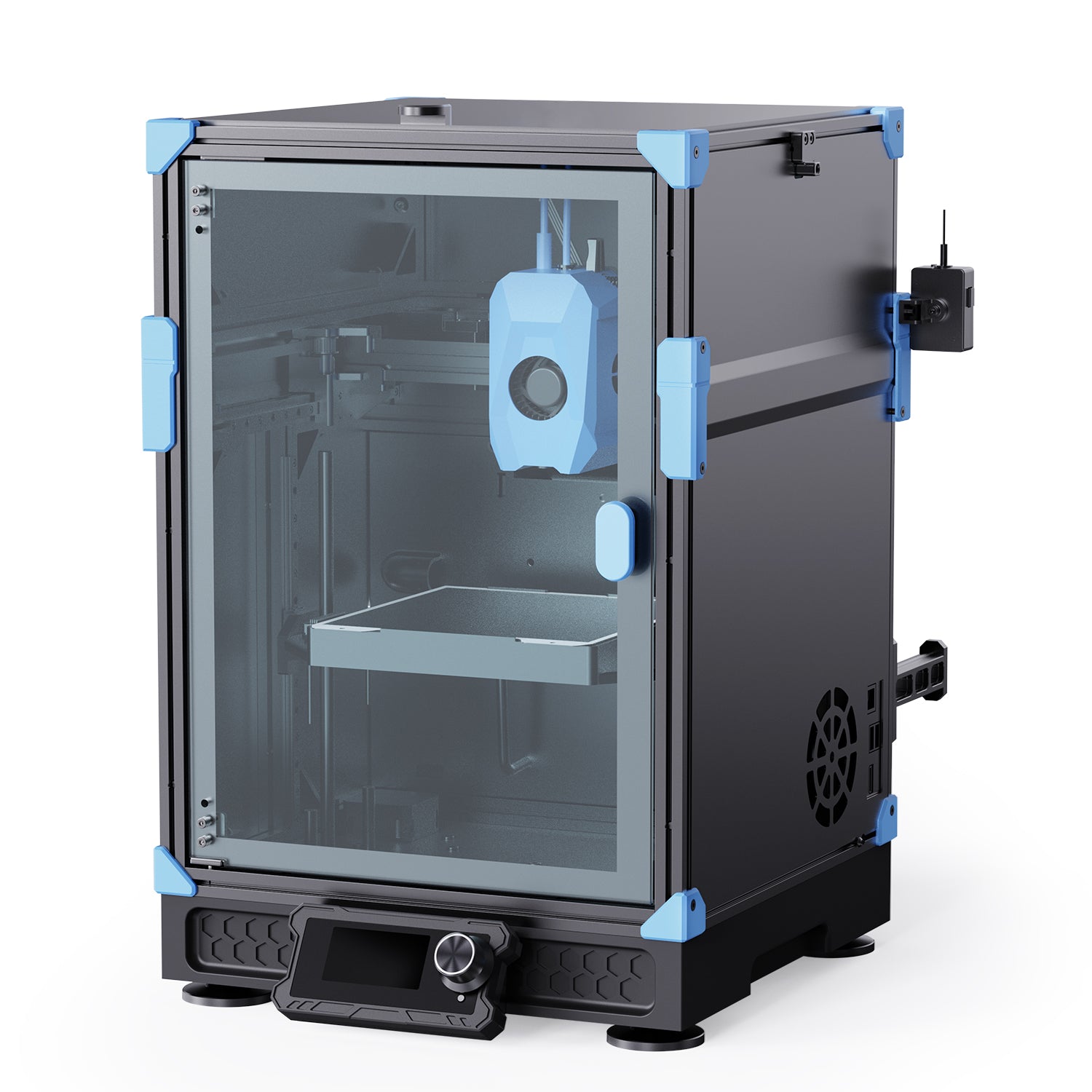

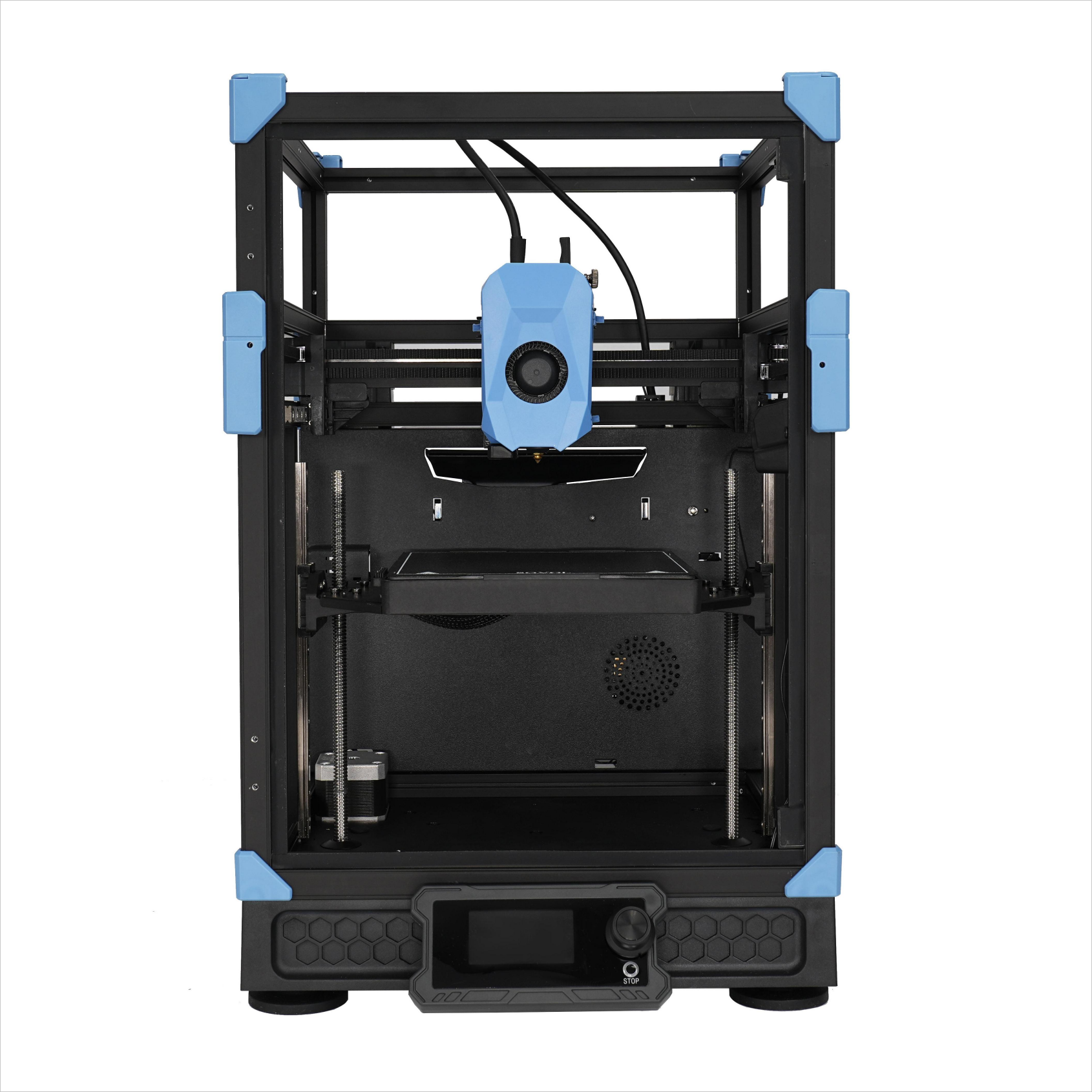

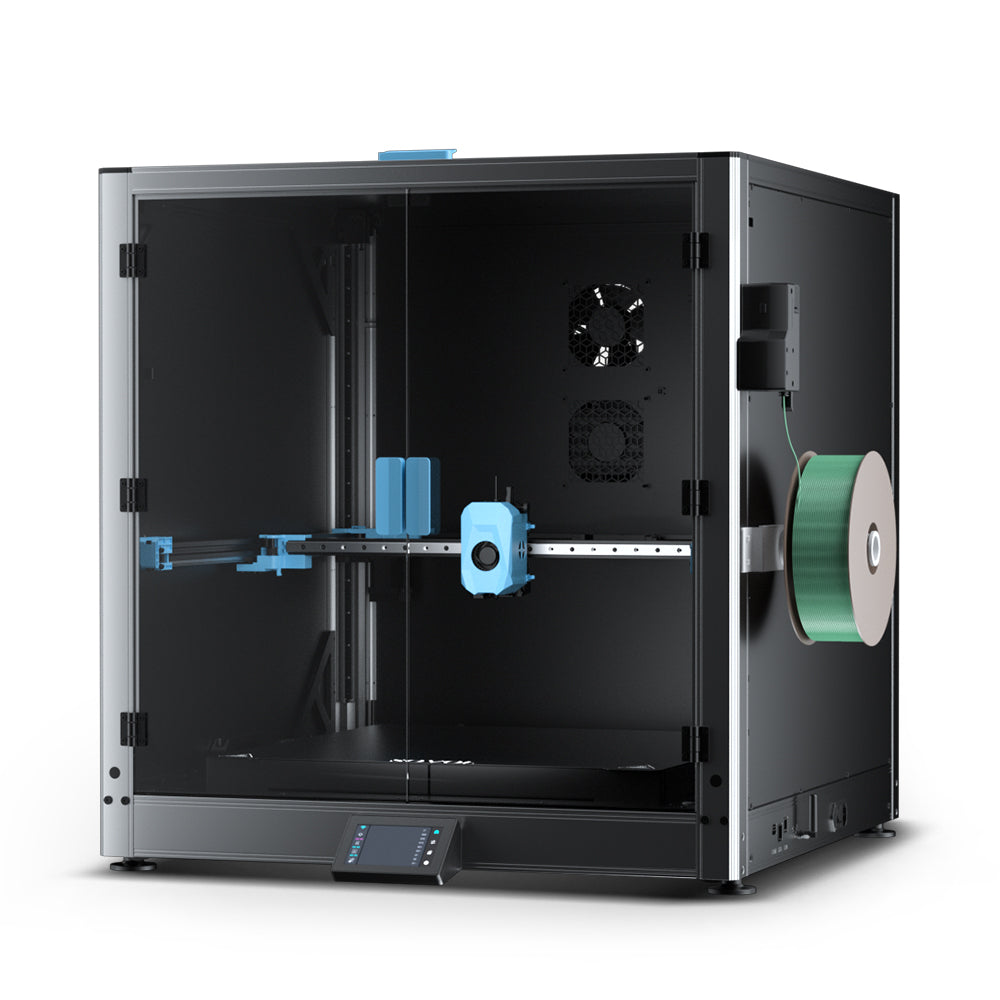

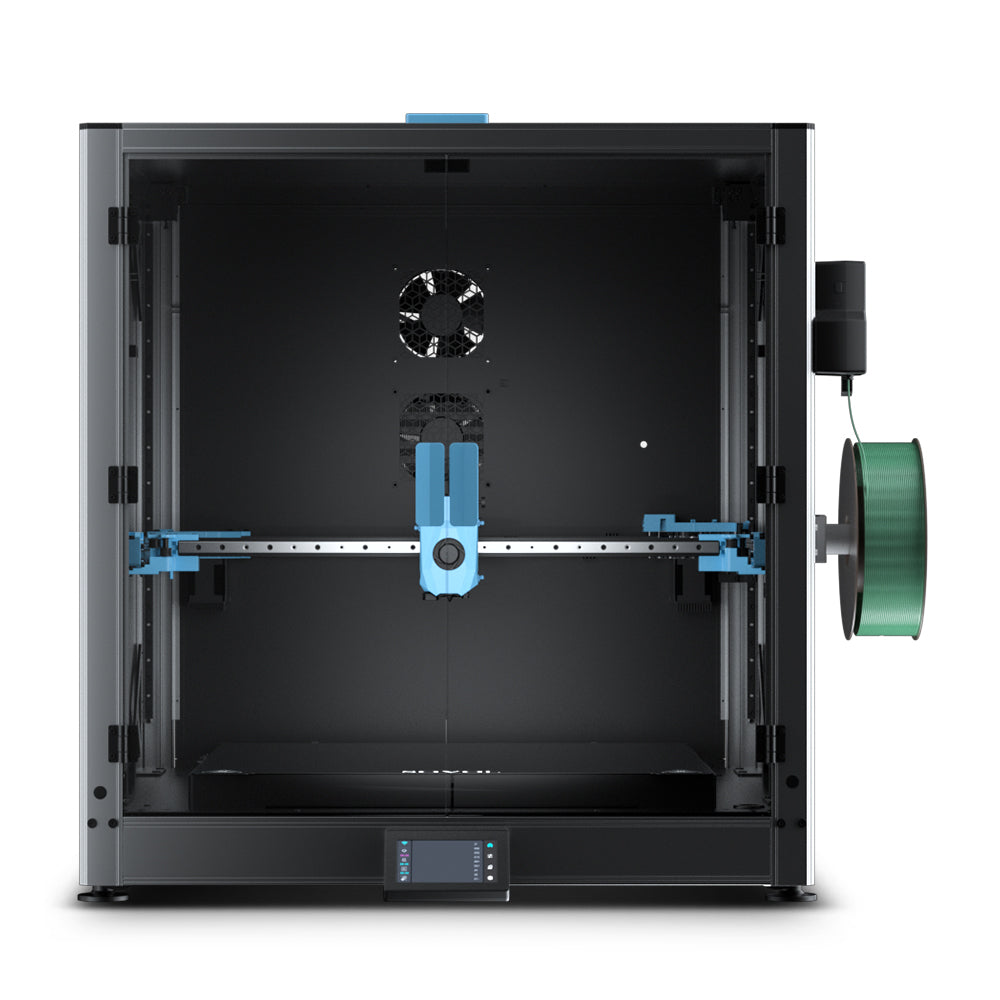

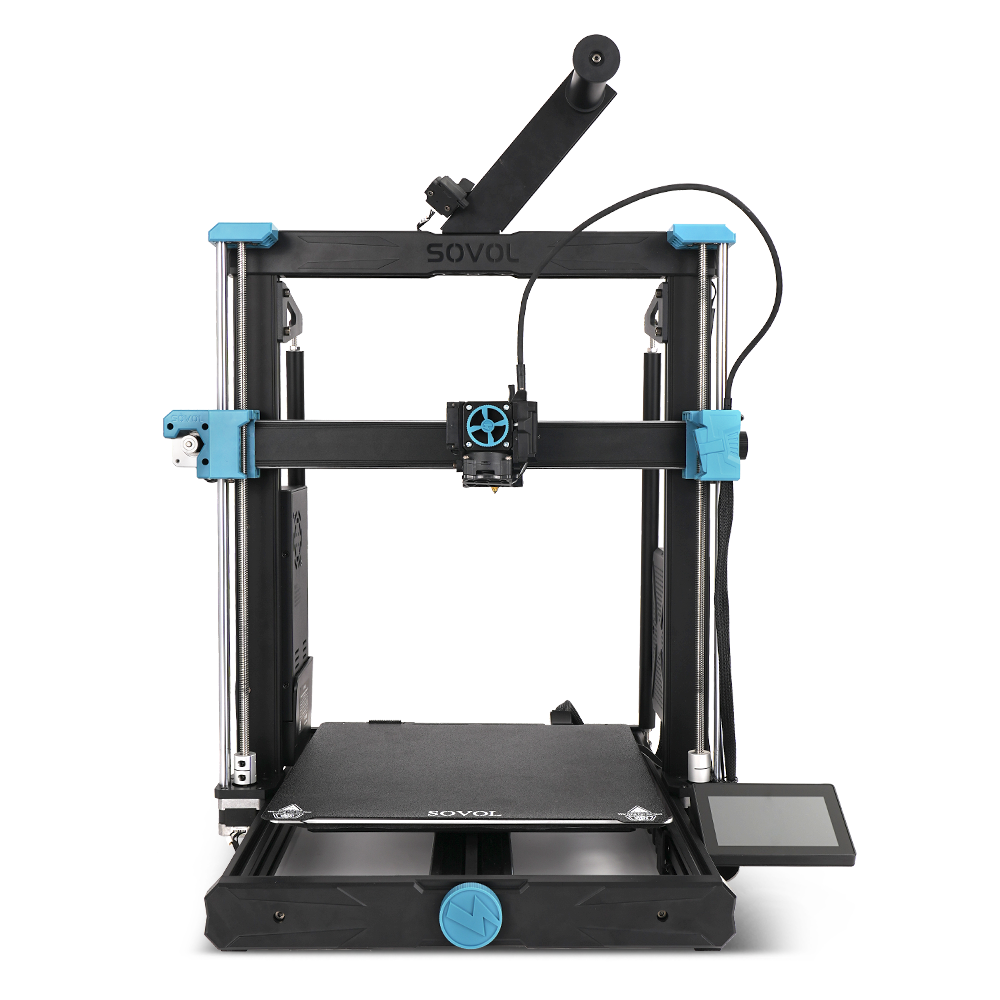

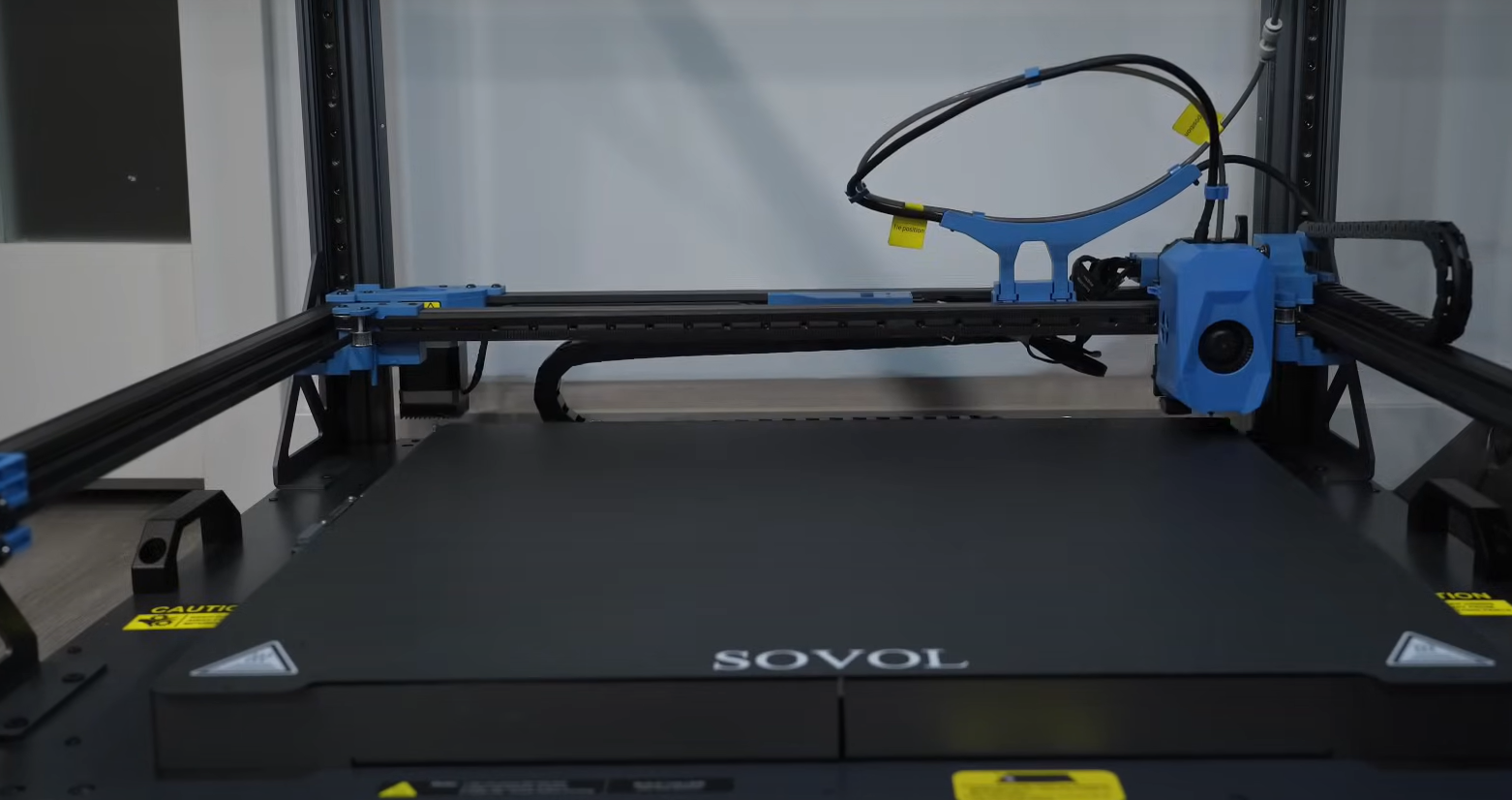

You also get advanced features with large 3d printers. The Sovol SV08 Max, for example, prints big and detailed parts in one run. Its heated bed and precise motion keep your prints strong and correct. You do not have to worry about warping or parts not lining up.

- Large-scale 3d printing supports unibody parts and tricky inside shapes.

- You can use more than one material in a single print, which gives you more design choices.

- You can print big art, furniture, or machine parts with smooth surfaces and strong structure.

Tip: Printing tricky shapes in one piece makes rapid prototyping faster. You can test your ideas quickly and make changes with less work.

Large-scale 3d printing also helps you save money. You use less material and spend less time putting things together. You can print when you need something, so you do not have to store extra parts. This way, you can go from idea to finished product fast.

You can see the effect in many jobs: - Aerospace teams print light, tricky parts for rockets. - Healthcare workers print custom implants and tools. - Artists and builders make big, detailed works with fewer steps.

When you use large 3d printers, you get new ways to design and test ideas. You can do projects that were too hard before. You get to focus on your ideas, not on what your tools can’t do.

Large-Scale 3D Printing Efficiency

Faster Production

You want to finish your projects fast. Large-scale 3d printing helps you do this. These printers can make big parts in one piece. You do not need to connect small pieces together. This helps you finish your work faster and make fewer mistakes.

Large-scale 3d printing lets you print many things at once. You can fill the print bed with different objects. This is helpful for small jobs or custom orders. You do not have to wait for one part to finish first. You can print everything together and save time.

Here are some ways large-scale 3d printing helps you work faster:

- You print big, tricky parts in one try, so you skip putting them together.

- You only print what you need, when you need it.

- You can let the printer run by itself, even at night.

- Software helps you watch your prints and keep things working well.

- You can use different materials and shapes in one print for custom jobs.

- Large-format 3d printers help you do more work with less effort.

- You get good quality and accuracy, even for small batches.

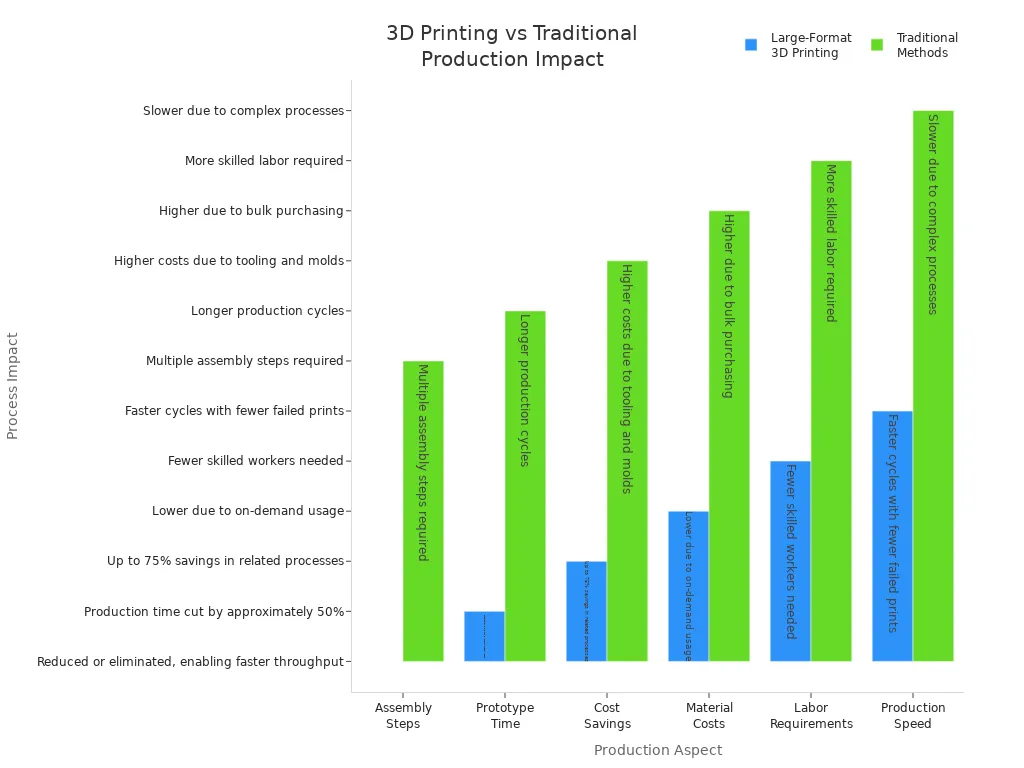

You can see how large-scale 3d printing and old methods compare in this table:

|

Production Aspect |

Large-Format 3D Printing Impact |

Traditional Methods Impact |

|---|---|---|

|

Assembly Steps |

Fewer or none, so you finish faster |

Many steps needed |

|

Prototype Time |

About half the time needed |

Takes longer |

|

Cost Savings |

Up to 75% less cost in some steps |

Costs more because of tools |

|

Material Costs |

Lower because you use only what you need |

Higher because you buy in bulk |

|

Labor Requirements |

Fewer skilled workers needed |

More skilled workers needed |

|

Production Speed |

Faster with fewer failed prints |

Slower because of more steps |

With large-scale 3d printing, you can react fast to new ideas. You do not need to wait for special tools or molds. You just change your design and start printing. This helps you keep up with trends and what people want.

Cost and Material Savings

Large-scale 3d printing saves you time and money. You use only what you need for each print. This means less waste and lower costs. You do not have to buy extra materials or store a lot.

Many companies use recycled plastics for 3d printing. You can turn old plastic into new filaments. This helps the planet and supports green practices. Studies show recycling 3d printed PLA and PETG cuts environmental impact by about half. You use less new material and make less trash.

Here is a table that shows how large-scale 3d printing helps with waste and being green:

|

Aspect |

Evidence Summary |

Implication for Material Waste Reduction |

|---|---|---|

|

Old plastic is made into filaments for 3D printing |

Helps cut plastic waste by reusing it |

|

|

Circular economy promotion |

3D printing lets you reuse waste plastics to make new parts |

Cuts down on using new materials and making waste |

|

Material limitations |

Recycled PLA gets weaker after many uses |

Shows there are some limits to reusing materials |

|

Recycling of common plastics |

PET, PLA, ABS, and polycarbonates from e-waste are made into filaments |

Shows you can keep plastic out of landfills |

|

Environmental impact |

Recycling 3D printed PLA and PETG cuts environmental impact by about 50% |

Proves you can lower waste and pollution by recycling |

Large-scale 3d printing also makes stronger parts. When you print a part in one piece, it is stronger than glued pieces. This means your projects last longer and work better.

Many industries now care about being green. Large-scale 3d printing fits these goals. You can use green materials, recycle old prints, and lower your impact on the earth. Food makers found that 3d printing can cut waste costs by up to 25%. This shows large-scale 3d printing is fast, flexible, and good for your wallet and the planet.

Tip: If you want to save money and help the earth, try large-scale 3d printing for your next project.

Real-World Impact

Maker Success Stories

Large-size 3d printers help makers do things they could not before. Many people use these printers to make big, cool projects. Here are some examples:

- Makers print big soft signs and SEG frames in one go. These signs grab attention for ads.

- You can make channel letters for brands much faster than old ways. These letters are great for stores and shows.

- Thermoforming molds print fast, so you can make many displays without mass production.

- Point of purchase displays use less material and dry quickly. This helps you launch products faster.

- Mobile billboards print in eight hours and can handle bad weather. They get noticed on busy streets.

- Huge selfie spots and big characters help events get popular and fun.

- Custom mannequins of famous people make store displays more fun and flexible.

- Exhibition props print in large amounts with cool lights.

- Interior decor like chairs, tables, and shelves fit any room. They are light and can glow.

- Lighting fixtures print hollow in one try. You get special shapes and built-in lights.

- Restoration jobs, like palace capitals from the 1800s, use large 3d printers. They copy details very well.

Artist Ioan Florea used large 3d printers to make molds for a house with liquid metal. The project needed models bigger than normal printers could make. Large industrial printers made it work.

Industry and Community Projects

Large-size 3d printers are used in many jobs. In building, these printers help make models, molds, and real building parts. Some projects use 3d printed joint knots for glass walls or molds for concrete in offices. These ways save time and help build in a greener way.

In schools, like Ann Richards High School, students use large 3d printers for hands-on work. They fixed up a camping trailer and learned about design and building. Makerspaces like Engine-4 in Puerto Rico let you print big models, custom drones, and IoT cases. These places help new companies, students, and tech groups.

You can also use large 3d printers for:

- Making new product models and parts

- Creating art and home decorations

- Making custom prosthetics

- Building cosplay outfits

- Helping with architecture and theater sets

- Helping engineers and designers try new ideas

Open-source projects like RepRap and MakerBot show how group 3d printing brings new ideas. These projects cut costs and let you change your tools for any building job.

|

Project |

Description |

Impact |

|---|---|---|

|

RepRap |

First open 3d printer kit design |

Started self-copying printer industry and many new projects |

|

MakerBot |

Group-made 3d printer development |

Helped people change and improve printers, shaping the market |

|

Shared manufacturing system |

Made prices lower and gave more people access to large 3d printing for building needs |

Challenges and Future Trends

Barriers to Entry

You might run into some problems when using large-size 3D printers. These problems can slow you down or make starting harder. Here are some of the main things that get in the way:

- Industrial 3D printers and their materials cost a lot. Some machines can cost millions of dollars.

- You need to know how to use CAD and run the printer. Many people and companies do not have these skills yet.

- Large printers need a lot of space. You have to plan where to put them and keep them safe.

- Making things fast and in big amounts is still hard. This can make big jobs cost more than old ways.

- There are not many material choices yet. You may not find the right certified materials for every job.

- Some jobs, like in aerospace and healthcare, have strict rules. Getting parts approved takes time and money.

- You need to do regular maintenance and calibration. This adds more work and costs to keep the printer working well.

- It is still hard to check quality and make sure every part is safe.

Here is a quick chart to show how costs compare:

|

Cost Aspect |

Small/Entry-Level 3D Printers |

Large/Professional 3D Printers |

|---|---|---|

|

Initial Investment |

$200 - $1,000 |

Up to $10,000 or millions (industrial) |

|

Monthly Maintenance |

$20 - $200 |

$20 - $200 (scales with complexity) |

|

Annual Maintenance |

$50 - $500 |

$50 - $500 (higher for complex parts) |

|

Parts Replacement |

$10 - $100 (basic) |

More expensive and frequent |

Note: If you want to make lots of the same thing, old ways might be cheaper. Large 3D printers are best for special, tricky, or small-batch jobs.

Accessibility and Innovation

Now, it is easier to try large-size 3D printing than before. New tech and help from others make it less hard to start.

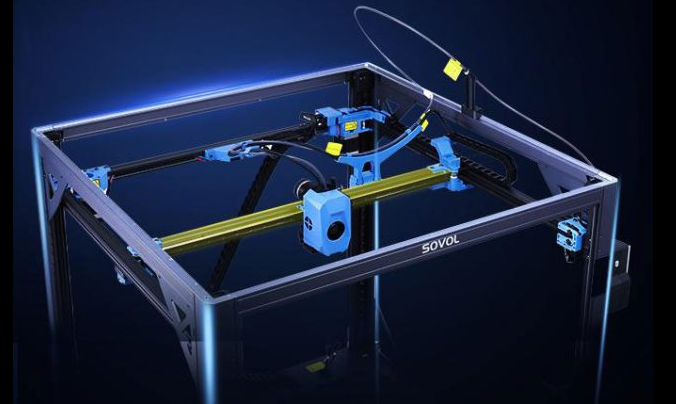

Large-format printers like the BigRep ONE use fused filament fabrication. This method is cheaper and simple to use. Dual extrusion lets you print tough shapes with supports that melt away. These printers are now more reliable and easy to use. You do not need as many skills to begin.

Makerspaces and 3D printing services let you try big printing without buying a printer. You can join a makerspace or use an online service to print large parts. This helps you learn and test ideas.

Open-source groups help make large 3D printers easier to use. You can share designs, change hardware, and use common parts. Projects like RepRap and MakerBot let you fix and upgrade your printer. This saves money and helps you be creative. This open way helps everyone come up with new ideas faster.

In the future, you will see better materials, faster printing, and more automation. AI and robots will make printing smarter and simpler. You will see more uses in jobs like aerospace and healthcare. The market for large 3D printers will grow fast. People will try to lower costs and help the planet. As tech gets better, you will have more chances to make big, custom things with less waste and more freedom.

Tip: Keep asking questions and learning new things. The future of large 3D printing will give you even more tools and ideas to try.

Large-size 3D printers give you new ways to create and save money. You can build complex shapes, combine parts into one, and try bold ideas. Makers use these printers to make art, furniture, and even building models. You work faster and waste less material.

- You can print big, detailed designs that were once impossible.

- You get more freedom to experiment and innovate.

- Many makers see faster results and lower costs.

Imagine what you could build next. The future of making looks bright with large 3D printers leading the way.

FAQ

What can you make with a large-size 3D printer?

You can print furniture, art, car parts, building models, and even house walls. These printers let you create big, strong, and detailed objects that smaller printers cannot handle.

How much space do you need for a large 3D printer?

You need a room or workshop with enough space for the printer and your projects. Some printers are as big as a refrigerator. Always check the size before you buy or set up.

Are large-size 3D printers hard to use?

You can learn to use them with practice. Many printers come with guides and software. Makerspaces and online videos help you get started. You do not need to be an expert.

What materials can you use in large 3D printers?

You can use plastics like PLA, ABS, PETG, and advanced materials such as carbon fiber, PEEK, or ULTEM™. Some printers also work with recycled plastics. Always check your printer’s material list.

Can you save money with large-size 3D printing?

Yes! You use less material and finish projects faster. You do not need to buy many tools or molds. Printing in one piece also means fewer repairs and less waste.