Choosing the right nozzle depends largely on understanding the difference between nozzles, especially between brass and hardened steel options. Brass nozzles are ideal for standard filaments like PLA or ABS, offering good print quality and quick heating. On the other hand, hardened steel nozzles are designed to handle abrasive filaments such as carbon fiber blends, providing greater durability and a longer lifespan. The key difference between nozzles lies in the type of filament they support, the quality of the print, their durability, and cost.

|

Factor |

Brass Nozzle |

Hardened Steel Nozzle |

|---|---|---|

|

Standard |

Abrasive |

|

|

Durability |

Lower |

Higher |

|

Cost |

Lower |

Higher |

Key Takeaways

- Brass nozzles get hot quickly. They work best with regular filaments like PLA and ABS. These nozzles give smooth and detailed prints. They also cost less money.

- Hardened steel nozzles last much longer than brass ones. They can handle tough and rough filaments like carbon fiber. But they heat up more slowly. You may need to use higher print temperatures with them.

- Choose brass nozzles if you do not print often. They are good for non-abrasive materials. You get good quality prints without spending a lot.

- Pick hardened steel nozzles if you print a lot. They are best if you use rough filaments. You will save money on replacements. They are strong and last a long time.

- Always use the right nozzle for your filament. This helps you get better print quality. It also stops nozzle damage or printing problems.

Nozzle Basics

What Are Nozzles?

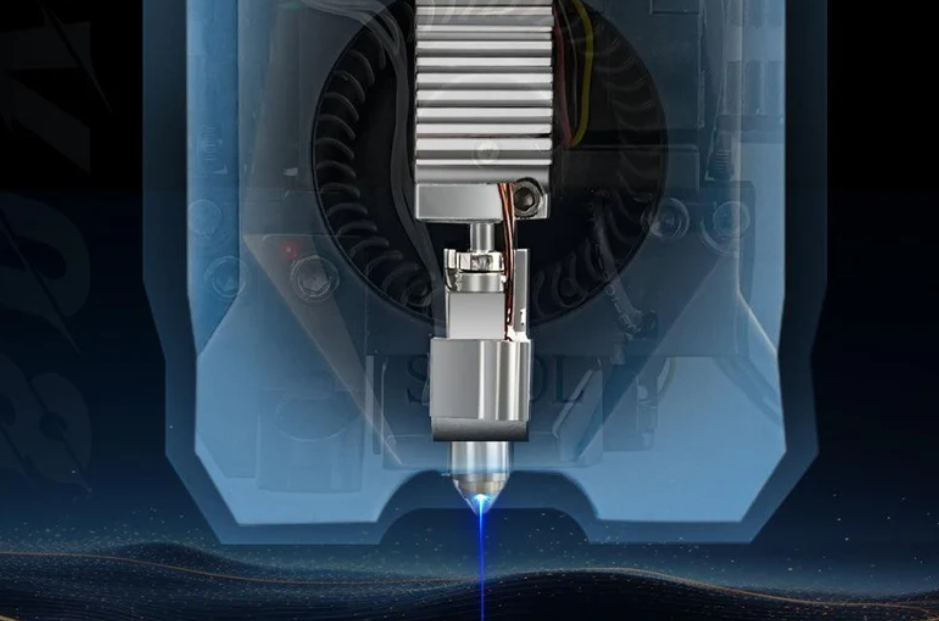

Nozzles are small but important parts of your 3D printer. You can think of them as the tip of a pen, but for melted plastic. When you print, the 3D printer heats up the filament until it melts. The melted filament moves through the nozzle and comes out in a thin line. This line builds up layer by layer to create your object.

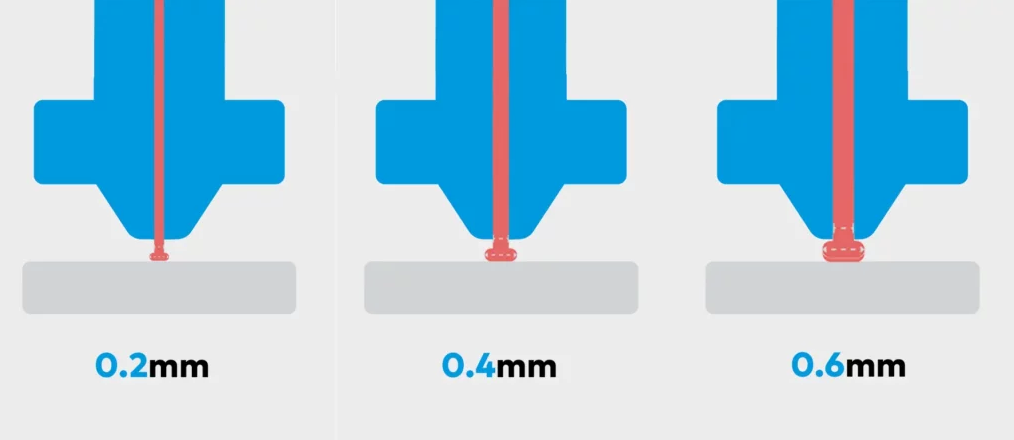

3d printer nozzles control how much melted filament comes out and where it goes. The size of the nozzle’s opening, called the orifice, affects how detailed your print will be. A smaller orifice gives you finer details, while a larger one lets you print faster. Nozzles also help keep the flow of filament steady, which is important for making sure your print looks good and matches the design.

Tip: If you want sharp details, choose a nozzle with a smaller opening. For bigger, faster prints, a larger nozzle works better.

Nozzles do more than just shape the filament. They also help control the temperature and make sure each layer sticks to the last one. This helps your prints stay strong and look smooth.

Why Nozzle Material Matters

The material your nozzles are made from can change how well your 3D printer works. Some nozzles heat up quickly and give you smooth, detailed prints. Others last longer, especially if you use tough or gritty filaments. For example, brass nozzles heat up fast and work well with regular filaments, but they wear out quickly if you use abrasive materials. Hardened steel nozzles last much longer with tough filaments, but they take more time to heat up.

3d printer nozzles made from special materials like tungsten carbide or ruby can handle lots of printing with rough filaments. These nozzles keep their shape and size for a long time, so your prints stay accurate. Good maintenance, like cleaning and using the right temperature, helps your nozzles last even longer.

Choosing the right nozzle material means you get better prints and spend less time fixing problems. You should always match your nozzle to the type of filament you use most.

Difference Between Nozzles

When picking a nozzle, you should know how they are different. You need to think about how well they move heat, how good your prints look, how long they last, and how much they cost. These things can change how your prints turn out and how easy printing is for you.

Thermal Conductivity

Thermal conductivity is how fast a nozzle heats up and keeps its heat. Brass nozzles heat up fast and keep the temperature steady. This helps your prints look smooth and nice. You can also print faster because the filament melts evenly.

Hardened steel nozzles heat up slower and may need more heat to work well. If you switch from brass to hardened steel, you might need to make the printer hotter by 5–10°C. If you do not do this, you could have problems like not enough filament coming out or layers not sticking. This matters if you want to print quickly.

Note: Brass nozzles heat up fast and give smooth prints. If you use tough filaments, you may need to change your settings for hardened steel.

Print Quality

Nozzle type also changes how your prints look. Brass nozzles give great print quality with regular filaments. They help you print small details and smooth surfaces. The heat spreads out evenly, so the filament comes out steady.

Hardened steel nozzles can also make good prints, but you might need to change your printer settings. Since they heat up slower, you could see small problems if you do not make it hotter. Some people do not notice much difference, but others see rougher surfaces or weak layers if they do not change the settings.

- Brass nozzles: Best for detailed prints with regular filaments.

- Hardened steel nozzles: Good for strong prints with tough filaments, but may need higher temperatures.

Durability

Durability is a big way nozzles are different. Brass nozzles work well with regular filaments like PLA or PETG. They can last for months or even a year if you use soft filaments. If you use tough filaments, brass nozzles can wear out after just a few prints. You might need to buy new ones often.

Hardened steel nozzles are much tougher. They last a lot longer, even with tough filaments like carbon fiber or glow-in-the-dark plastics. You can print for many weeks or months before they wear out. This makes them better if you use gritty or hard filaments.

|

Nozzle Material |

Filament Type |

Average Lifespan |

Notes |

|---|---|---|---|

|

Brass |

Standard (e.g., PLA) |

Lasts very long with non-abrasive filaments; typical lifespan 4-8 weeks with regular use |

|

|

Brass |

Abrasive |

4-8 weeks |

Wears out quickly with abrasive filaments |

|

Hardened Steel |

Standard (e.g., PLA) |

15-30 weeks or longer |

Lasts significantly longer than brass; suitable for abrasive filaments |

|

Hardened Steel |

Abrasive |

15-30 weeks or longer |

Recommended for abrasive filaments due to high durability |

If you want your nozzle to last a long time, pick hardened steel.

Cost

Cost is another thing to think about. Brass nozzles are cheaper at first. You can get them for $8–$20 each. If you only use regular filaments, you will not need to buy new ones often, so they are a good deal.

Hardened steel nozzles cost more, usually $10–$30 each. They last much longer, especially with tough filaments. If you print with hard materials, you will save money over time because you will not need to buy new nozzles as often.

|

Aspect |

Brass Nozzles |

Hardened Steel Nozzles |

|---|---|---|

|

Initial Purchase Cost |

Moderately expensive, typically $10–$30 |

|

|

Durability |

Wears out quickly with abrasive filaments, leading to frequent replacements |

Highly durable, resists wear from abrasive filaments, resulting in less frequent replacements |

|

Suitability |

Best for hobbyists using non-abrasive filaments on a budget |

More cost-effective long-term for heavy-duty or abrasive filament printing |

Tip: If you print a lot with tough filaments, hardened steel nozzles can save you money over time.

How These Differences Affect Your Printing

The nozzle you pick changes how you print and what your prints look like. Brass nozzles heat up fast and give great prints with regular filaments. They are easy to use and cost less. If you use tough filaments, they wear out quickly and need to be replaced often.

Hardened steel nozzles last much longer and can handle any filament, even the toughest ones. You might need to make your printer hotter, but you will not need to change nozzles as much. This makes printing easier and more reliable.

- If you want the best print quality and use regular filaments, pick brass nozzles.

- If you want your nozzle to last and use tough filaments, pick hardened steel nozzles.

The best nozzle for you depends on what you print, how often you print, and what matters most: print quality, durability, or cost.

Brass Nozzles

Pros of Brass Nozzles

Brass nozzles have many good points for 3D printing. They are simple to use and work well for most jobs. Many people pick brass nozzles for these reasons:

- They heat up fast and keep the temperature steady.

- They cost less, so you can save money.

- They work with many non-abrasive filaments like PLA, ABS, and PETG.

- They are easier to clean than other nozzle types.

- They give smooth prints and good quality with non-abrasive materials.

Tip: Brass nozzles are best for non-abrasive filaments. You will get steady prints and fewer issues.

Cons of Brass Nozzles

Brass nozzles also have some problems you should know. Here are some common issues:

- They wear out fast if you use abrasive filaments like carbon fiber or glow-in-the-dark.

- The tip can get round and the hole can get bigger, which makes prints look worse.

- You may need to replace them often if you use anything but non-abrasive filaments.

- Cleaning with too much heat can hurt brass nozzles, so be gentle.

- They do not work well with glass fiber, wood, or other rough additives.

Note: If you want to print with abrasive materials, try a stronger nozzle.

Best Uses for Brass Nozzles

Brass nozzles are great for non-abrasive filaments. They work best with PLA, ABS, and PETG, which are used in many projects. Brass nozzles are good for normal prints and regular heat settings. If you want smooth prints and fine details, brass nozzles are a good pick.

- Pick brass nozzles for daily printing with non-abrasive filaments.

- Use them if you want nice prints and do not want to spend a lot.

- Do not use brass nozzles for abrasive or metal-filled filaments, or they will wear out fast.

Hardened Steel Nozzles

Pros of Hardened Steel Nozzles

Hardened steel nozzles are great for printing with tough materials. They do not wear out fast, even after lots of use. You can use them with abrasive filaments like carbon fiber or metal-filled plastics. These nozzles do not scratch or get damaged easily, so you do not need to change them often.

- You can print with abrasive filaments for a long time.

- The nozzle keeps its shape and lasts longer.

- These nozzles are good for big jobs or factory use.

- You save money because you do not buy new nozzles often.

Tip: If you print big things or use your printer a lot, hardened steel nozzles are a good pick.

Cons of Hardened Steel Nozzles

Hardened steel nozzles have some problems you should know about. They heat up slower than brass nozzles. Sometimes, your prints may have small holes or rough spots, especially with flexible filaments like TPU. The inside of the nozzle is not as smooth, so the filament does not flow as well.

|

Drawback Aspect |

Hardened Steel Nozzles Drawbacks |

|---|---|

|

Thermal Conductivity |

They do not heat up as well, so you may need higher temperatures and slower speeds, especially with flexible filaments like TPU. |

|

Surface Finish |

The inside is a bit rough, which can make prints less smooth. |

|

Corrosion Resistance |

They can rust if they get wet, unlike stainless steel. |

|

Food Safety |

Not good for food-safe prints because of possible lead or coatings. |

|

Print Quality Impact |

Lower heat and rougher inside can cause gaps or rough prints, especially with soft or wet filaments. |

|

Compatibility |

They are strong for tough filaments, but not as good for flexible or wet filaments unless you change settings. |

You might need to make your printer hotter and print slower for better results. Hardened steel nozzles are not good for food-safe prints or printing in wet places because they can rust.

Best Uses for Hardened Steel Nozzles

Use hardened steel nozzles when you need strong wear resistance and want to print with tough filaments. They work best in factories, long projects, or with big nozzle sizes. If you use carbon fiber, glass-filled, or metal-filled filaments, these nozzles are the best choice. They are also good if you print a lot or for many hours.

- Pick hardened steel nozzles for carbon fiber, metal, or glass-filled filaments.

- Use them for big prints or when you want your nozzle to last.

- Do not use them for food-safe prints or with flexible filaments unless you change your settings.

Note: For the best results, use hardened steel nozzles for tough jobs and switch to other nozzles for regular or food-safe filaments.

Nozzle Comparison

Material Compatibility

When picking nozzles, you should think about what filaments you use. Brass nozzles work well with regular filaments like PLA, ABS, PETG, Nylon, and TPU. They heat up fast and make smooth prints. But brass nozzles wear out quickly if you use rough filaments like carbon fiber or metal-filled ones.

Hardened steel nozzles can handle more types of filaments. You can use them with both regular and rough filaments. They last longer when printing with tough materials. But they are not good for food-safe prints because some coatings might have lead. Some special nozzles, like ruby or tungsten, are even stronger. These are best for really rough filaments, but they cost more money.

Here is a simple guide to help you pick the right nozzle for your filament:

|

Nozzle Material |

Compatible Filaments |

Durability & Notes |

|---|---|---|

|

Brass |

PLA, ABS, PETG, Nylon, TPU (non-abrasive) |

Good for daily use; wears out fast with rough filaments |

|

Hardened Steel |

Carbon fiber, metal-filled, glow-in-the-dark, PLA, ABS, PETG |

Best for rough filaments; not food-safe; lasts longer |

|

Specialty |

Tungsten, Ruby (for extreme abrasion) |

Super strong; costs more; for special jobs |

Tip: Pick a nozzle that matches the filament you use most. This helps your prints look better and keeps your printer working well.

Maintenance Tips

You need to care for your nozzles to keep prints looking nice. Brass nozzles need to be cleaned often. You can use heat-and-push or cold-pull methods to clear clogs. Cleaning filaments also help. If you print a lot, change brass nozzles every six months, or sooner if you use rough filaments. Do not scrape the nozzle on the glass bed. Use a silicone sock to stop stuff from sticking.

Hardened steel nozzles do not need as much cleaning because they are tough. Still, check for clogs and keep an extra nozzle ready. These nozzles cost more, but you will not need to buy new ones as much. Special nozzles with coatings might need special tools for cleaning.

Here is a table to help you remember how to care for your nozzles:

|

Nozzle Type |

Maintenance Practices |

Replacement Frequency |

Extra Tips |

|---|---|---|---|

|

Brass |

Clean often; do not scratch; use silicone sock |

Every 6 months or sooner |

Heat before cleaning for best results |

|

Hardened Steel |

Clean less; check for clogs |

Not as often |

Keep extras; lasts longer |

Remember: Clean nozzles make your prints better and help your printer last longer.

Choosing the Right Nozzle

Filament Type

First, think about what filament you use most. Brass nozzles are best for regular filaments like PLA, ABS, and PETG. These nozzles heat up fast and make smooth prints. If you use rough filaments, like carbon fiber or metal-filled ones, you need a hardened steel nozzle. Hardened steel does not wear out fast and keeps its shape after many prints. But it heats up slower and might need higher temperatures to work well. Always pick a nozzle that matches your filament. This helps stop quick wear and bad print quality.

Print Frequency

How much you print is important too. If you only print sometimes, a brass nozzle will last a long time with normal filaments. If you print every day or do big jobs, you should use a hardened steel nozzle. Printing a lot with rough filaments can ruin brass nozzles quickly. Hardened steel nozzles last longer and you will not need to change them as much.

Tip: If you use rough filaments a lot, switch to hardened steel. This helps you avoid changing nozzles all the time.

Budget

Your money matters when picking a nozzle. Brass nozzles are cheaper and work well for most regular prints. But if you print a lot or use rough filaments, you might need to buy new ones more often. Hardened steel nozzles cost more at first but last longer, especially with rough filaments. Over time, you might save money because you do not need to buy new nozzles as much.

|

Nozzle Type |

Upfront Cost |

Lifespan with Abrasive Filaments |

Best For |

|---|---|---|---|

|

Brass |

Low |

Wears out quickly |

Occasional, standard use |

|

Hardened Steel |

Higher |

Frequent, tough jobs |

User Level

How much you know about 3D printing can help you choose. If you are new or want to print small, detailed things, brass nozzles are a good pick. They are easy to use and work well with regular filaments. If you have more experience or want to use rough or special filaments, try hardened steel nozzles. People who print big things or use filled filaments will like how tough hardened steel is.

- Beginners: Pick brass for easy use and nice prints.

- Advanced users: Use hardened steel for hard jobs and longer nozzle life.

Picking the right nozzle is about what you need. Brass nozzles are good for normal filaments like PLA, ABS, or PETG. They give nice prints and help you spend less money. Hardened steel nozzles are better if you use rough filaments like carbon fiber or metal-filled ones. They last longer and do not wear out fast. Here is a simple checklist to help you pick:

- Choose brass for regular, non-abrasive filaments.

- Use hardened steel for rough or special filaments.

- Switch to hardened steel if you print a lot or use tough materials.

Tip: Think about what you want to print in the future before picking your nozzle.

FAQ

What happens if you use abrasive filament with a brass nozzle?

You will notice your brass nozzle wears out quickly. Abrasive filaments like carbon fiber or glow-in-the-dark types can make the nozzle hole larger. This leads to poor print quality and rough surfaces.

Can you switch between brass and hardened steel nozzles easily?

Yes, you can swap nozzles on most 3D printers. Always let the nozzle cool before changing it. Use the right tools to avoid damage. Check your printer’s manual for safe steps.

Do you need to change print settings when using a hardened steel nozzle?

You should increase the print temperature by 5–10°C. Hardened steel does not heat up as fast as brass. This helps the filament flow smoothly and keeps your prints strong.

How do you know when to replace your nozzle?

Look for signs like uneven extrusion, rough print surfaces, or under-extrusion. If you see these problems, your nozzle may have worn out. Replacing it restores print quality.

Are hardened steel nozzles food-safe?

Hardened steel nozzles are not food-safe. They may contain coatings or metals that can contaminate prints. If you want to print food-safe items, use a stainless steel nozzle instead.