To get a fast 3D printer, you need to focus on a few key features. Look at the motion system, hotend and extruder, smart firmware, frame strength, slicer settings, and nozzle size. Each part affects speed and quality. If you want to save time, you must balance these systems. You cannot push speed without keeping prints strong and accurate.

Key Takeaways

- Look at important parts like motion systems, hotends, and firmware to make your 3D printer faster.

- Make sure speed and print quality are balanced. Fast prints can cause problems if you do not control them well.

- Pick a CoreXY motion system for more speed and better stability in your 3D printer.

- Use high-flow hotends and smart firmware to help material move better and make prints more reliable.

- Change slicer settings to make prints faster but still keep them looking good.

What Defines a Fast 3D Printer

Speed vs. Quality and Reliability

When you want a fast 3D printer, speed is important. But you also need good print quality and reliability. If you make the printer go too fast, prints can break or shift. Sometimes, the nozzle can get jammed. Think about a race car. It needs strong tires and a tough frame to go fast. A 3D printer needs strong parts too. You want each layer to stick well. You also want details to look nice.

Experts check print speed by how much material is used over time. For fdm 3d printing, speed is in millimeters per second (mm/s). For lcd 3d printing, it is in layers per hour. The best speed and quality depends on your project. If you need a quick model, lower resolution is okay. If you need a final part, every layer should be perfect.

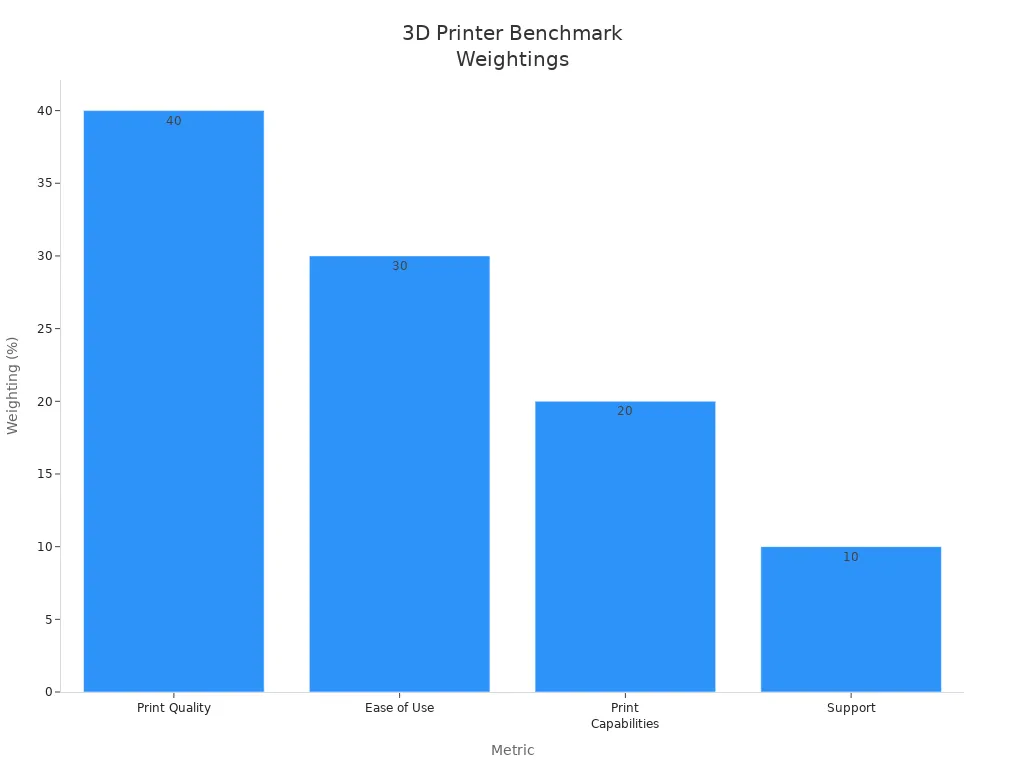

Tip: Industry tests show print quality matters most (40%). Ease of use is next (30%). Print capabilities get 20%. Support is last with 10%.

|

Metric |

Weighting (%) |

|---|---|

|

Print Quality |

40 |

|

Ease of Use |

30 |

|

Print Capabilities |

20 |

|

Support |

10 |

Key Features for High-Speed Printing

A fast 3D printer needs many features working together. These features are like players on a team. Each one helps the printer work better and faster. Here are the main features that help with speed:

- Motion system: CoreXY and linear rail designs help the printer move fast and smooth.

- Hotend and extruder: A high-flow hotend and strong extruder push more material without clogging.

- Firmware: Smart firmware like Klipper and input shaping control movement and stop shaking.

- Frame: A strong frame keeps the printer steady when moving fast.

- Slicer settings: Changing acceleration, jerk, and layer height can make prints faster.

- Nozzle size: A bigger nozzle puts down more material each time, so prints finish quicker.

- Material compatibility: Some materials work better at high speed than others.

|

Feature |

Description |

|---|---|

|

Print Speed |

Needed to make things faster, especially for lots of prints. |

|

Resolution |

Needed for sharp details; higher resolution can slow printing. |

|

Material Compatibility |

Shows which materials work well for fast printing. |

|

AI-Assisted Optimization |

Makes printing better by changing settings while printing. |

You should watch for problems like nozzle jams or prints coming loose. Sometimes, layers do not stick well. Always balance speed, quality, and reliability. If you only care about speed, you might have to fix failed prints later.

Motion System and Speed

The motion system acts as the backbone of any fast 3D printer. It decides how quickly and accurately the print head moves across the build area. If you want to boost print speed, you need to understand how different motion systems work and why some designs outperform others.

CoreXY vs. Bedslinger

You will find two main types of motion systems in fdm 3d printing: CoreXY and bedslinger. Each system moves the print head and bed in a unique way.

- CoreXY: This design keeps the print bed still while the print head moves in both the X and Y directions. The belts and motors work together, so the print head glides quickly across the frame. You get less vibration and more control. This setup lets you print at higher speed without losing quality.

- Bedslinger: In this system, the bed moves back and forth while the print head moves side to side. The moving bed adds weight and inertia. When you try to print fast, the bed can shake, and layers may shift. This can hurt print quality, especially for tall or detailed models.

Tip: CoreXY systems let you print faster because the print head moves over a stationary bed. This reduces vibrations and keeps each layer in place. You get more accurate prints, even at high speed.

Here is a quick comparison:

|

Feature |

CoreXY |

Bedslinger |

|---|---|---|

|

Bed Movement |

Stationary |

Moves during printing |

|

Speed |

High |

Moderate |

|

Vibration |

Low |

Higher at fast speeds |

|

Print Quality |

Consistent at high speed |

Can drop at high speed |

|

Best For |

Fast, precise printing |

Simpler, slower prints |

If you want a fast 3D printer that saves you time and keeps your prints strong, CoreXY stands out. It works well with advanced features like Klipper firmware and input shaping, which further boost speed and accuracy.

Linear Rails and Stability

Linear rails play a key role in keeping your printer stable at high speed. These rails guide the print head smoothly along its path. You get less wobble and more precise movement, which means better print quality.

- Linear rails support all axes, so the print head stays on track, even during quick moves.

- The low friction of linear rails lets the printer move fast without jerking or skipping steps.

- You will notice sharper details and smoother contours, especially when printing complex shapes or using lcd 3d printing for fine layers.

Note: Linear rails also last longer and need less maintenance. You spend more time printing and less time fixing your machine.

Motion system advancements do not work alone. They need a strong frame to hold everything steady. They also rely on smart firmware to control movement and adjust for any shake or vibration. When you combine CoreXY, linear rails, and advanced firmware, you get a system that prints layer by layer with speed and precision.

- High-resolution extruders and linear rails work together to deposit material exactly where you want it.

- Sensors can give real-time feedback, letting the printer adjust speed and keep each layer perfect.

- This synergy means you do not have to choose between speed and quality. You get both.

In summary:

If you want to print fast without losing quality, focus on the motion system. Choose CoreXY for speed and stability. Add linear rails for smooth, accurate movement. Make sure your printer’s frame and firmware can keep up. This balance gives you reliable, high-quality prints every time.

Hotend, Extruder, and Flow Rate

High-Flow Hotends

A high-flow hotend is needed for a fast 3d printer. This part melts filament and pushes it out the nozzle. With a high-flow hotend, you can print more material quickly. You can finish big models or test prints faster. The hotend’s temperature and nozzle size change how much filament you use. Bigger nozzles and hotter temps make printing faster, but quality can change.

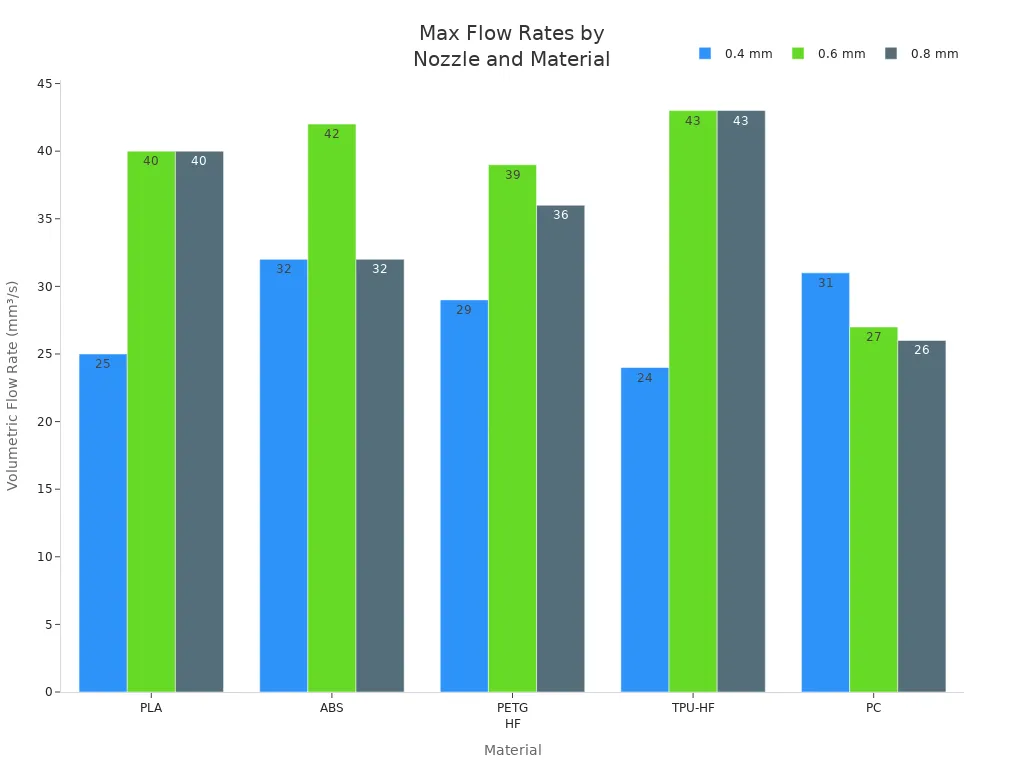

Here is a table that shows how nozzle size and material affect flow rate:

|

Nozzle Diameter (mm) |

Material |

Hotend Temperature (°C) |

Volumetric Flow Rate (mm³/s) |

|---|---|---|---|

|

0.4 |

PLA |

220 |

25 |

|

0.6 |

PLA |

220 |

40 |

|

0.8 |

PLA |

220 |

40 |

|

0.6 |

ABS |

270 |

42 |

|

0.8 |

TPU-HF |

230 |

43 |

You can see that higher flow rates mean faster printing. All-metal hotends work with high-temp materials like nylon and PETG. These upgrades help you print faster and more reliably. In fdm 3d printing, a high-flow hotend, strong extruder, and smart firmware like Klipper firmware keep printing smooth.

Direct Drive vs. Bowden

You have to pick between direct drive and Bowden extruder setups. Each one changes how you feed filament and how fast you print.

- Direct Drive: The extruder is close to the hotend. You get better control with flexible or rough filaments. This setup is good for lcd 3d printing and fdm 3d printing when you want high detail or quick tests. It may be a bit slower because of extra weight, but you get better quality.

- Bowden Extruder: The extruder is farther from the hotend. The print head is lighter and moves faster. You can print simple shapes quickly, but flexible filaments can jam. Bowden works best with hard materials like PLA and ABS.

Here is a quick comparison:

|

Feature |

Direct Drive |

Bowden Extruder |

|---|---|---|

|

Filament Compatibility |

Handles flexible and abrasive materials |

Best for rigid materials |

|

Print Speed |

Slower, better control |

Faster, may reduce quality |

Tip: Direct-drive extruders and all-metal hotends let you print with more types of filament. You get better results with nylon, PETG, and flexible materials. Bowden setups are faster for simple prints, but quality can drop on tricky designs.

You need to balance speed, quality, and reliability. Fast 3d printer features like high-flow hotends and direct-drive extruders work with motion systems and firmware. You get faster prints, strong layers, and sharp details. In sla 3d printing, dlp 3d printing, and lcd 3d printing, the right extruder setup helps you finish jobs faster and with fewer mistakes. Always check how each part works with the others in the 3d printing process. When everything works together, you get the best results for quick testing and making parts.

Conclusion:

Pick a hotend and extruder that fit your speed and material needs. Upgrade to all-metal hotends and direct-drive systems for flexible filaments and high-heat jobs. Use Bowden setups for fast and easy prints. Remember, every part must work together for the best print speed and layer quality.

Firmware, Slicer, and Print Settings

Advanced Firmware Features

You can make a fast 3D printer work even better by updating its firmware. New firmware like Klipper gives you special tools to help your printer go faster and keep prints looking good. Klipper firmware uses a Raspberry Pi to do hard math. This lets your printer handle more steps every second and move more accurately. Input Shaping and Smooth Pressure Advance help stop shaking and leaking. You get cleaner prints, even when printing fast.

Tip: Input Shaping works like car shock absorbers. It helps smooth out quick moves. Your printer can lay down each layer with less shaking.

Here is a simple table comparing firmware options:

|

Feature |

Klipper Firmware |

Traditional Firmware (e.g., Marlin) |

|---|---|---|

|

Processing Power |

Uses Raspberry Pi for fast G-code |

Limited to printer’s onboard chip |

|

Step Rate |

Over 600,000 steps per second |

About 10,000 steps per second (8-bit) |

|

Print Quality |

Enhanced by Input Shaping, Pressure Advance |

Standard, fewer advanced features |

You get faster prints and better quality when you use advanced firmware with a strong motion system like CoreXY and linear rails.

Slicer Settings for Speed

Slicer software tells your printer how to move. You can change settings like acceleration, jerk, infill speed, and infill pattern. Higher acceleration and jerk make your printer reach top speed faster. But they can cause problems like ghosting. Lower settings slow things down but make prints look better and help your printer last longer.

- Print speed: Controls how fast the print head moves.

- Acceleration: Sets how quickly the printer speeds up.

- Jerk: Decides how fast the printer changes direction.

- Infill pattern and density: Simple patterns and less infill print faster.

Note: In fdm 3d printing, lcd 3d printing, and dlp 3d printing, slicer settings work with firmware to balance speed and quality. Smart slicer updates can make prints faster by picking quick infill patterns and thicker layers.

Nozzle Size and Layer Height

Nozzle size and layer height change how your printer puts down material. A bigger nozzle lets you print thicker layers, so you finish faster. For example, a 0.6mm nozzle with a 0.2mm layer height prints quicker than a 0.4mm nozzle. The best starting point is a nozzle size-to-layer height ratio of 1:3.

- Thicker layers print faster but may lose small details.

- Thinner layers look better but take longer.

- Nozzle diameter sets the range for layer heights.

In fdm 3d printing and lcd 3d printing, you can change layer height in your slicer. This helps you pick between speed and detail for each print. In sla 3d printing and dlp 3d printing, layer thickness also changes speed and how smooth the print looks.

In summary:

You can get fast and strong prints by changing firmware, slicer, and nozzle settings. All parts must work together. If you go too fast, you might lose quality. Always balance speed, reliability, and print quality for the best results.

Frame, Power, and Cooling

Rigid Frame Importance

A rigid frame is needed to keep your fast 3D printer steady. If the frame is weak, it can shake or bend when printing fast. This shaking can make layers move and mess up high resolution prints. A strong frame keeps all parts in place. This helps your printer build each layer with care. When you use CoreXY motion systems or linear rail guides, a solid frame helps these features work well. You can print faster without losing quality.

A rigid frame also works with smart firmware like Klipper firmware and input shaping. These systems help control movement and stop shaking. But they need a strong base to work right. If your frame is weak, even the best firmware cannot stop shaky prints. You get better prints when all parts work together.

Power Supply and Cooling

Your power supply must be steady for high-speed printing. If the power goes up or down, your printer can stop or make mistakes. Steady power keeps all parts working well. This helps you avoid problems. Fast fdm 3d printing uses more energy, especially for heated beds and high-flow hotends. If you print faster, you might need a bigger power supply.

- Watt density is important. If you make your printer twice as big, you need twice the power to keep it working well.

- Line speed changes how much power you need. Printing faster uses more energy.

Cooling is also very important. When you print fast, each layer must cool quickly to keep its shape. If cooling is too strong, you might see cracks or brittle parts. If cooling is too weak, layers can sag or melt together. You need to balance cooling for each material. PLA needs lots of cooling for sharp details. ABS and ASA need less cooling to stop warping. PETG works best with medium cooling.

|

Cooling Issue |

Symptoms |

Fix / Solution |

|---|---|---|

|

Cooling Too Strong |

Cracks, weak adhesion, brittle parts |

Lower fan speed, raise enclosure temperature |

|

Cooling Too Weak |

Stringing, sagging, melted corners |

Increase fan speed, lower nozzle temp, slow speed |

You can make cooling better with dual duct mods, strong fans, or even liquid cooling for advanced printers. Enclosures help keep the right temperature for materials like ABS. Good cooling duct design moves air well and keeps print quality high, especially in fdm 3d printing and lcd 3d printing.

Conclusion:

You get the best prints when your frame, power supply, and cooling all work together. A strong frame helps your printer move fast. Steady power keeps your printer working right. Good cooling protects each layer and keeps high resolution. Always check these things before trying to print faster.

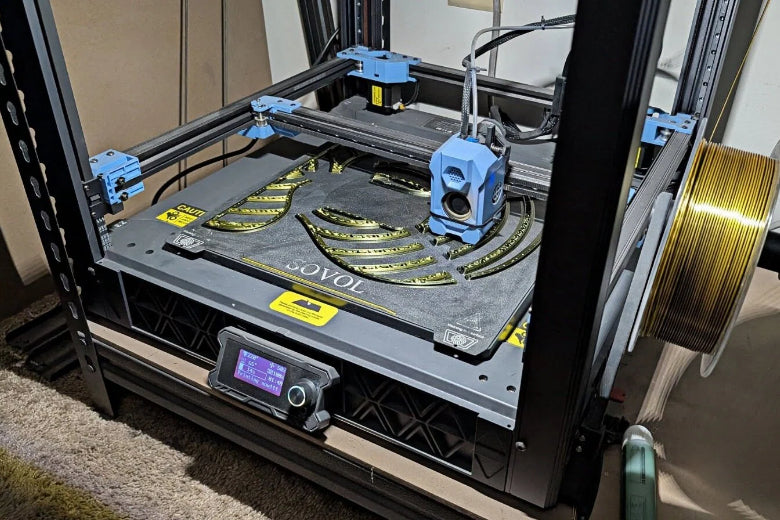

You need all parts working together for fast 3D printing. Motion, power, and smart controls help each layer. Printers like SOVOL SV08 use CoreXY, linear rails, high-flow hotend, and Klipper firmware. These features work together as a team. Here is what top models have:

|

Printer Model |

Key Features |

|---|---|

|

SOVOL SV08 |

CoreXY, linear rail, Klipper |

|

Smart print head, reliability |

|

|

AnkerMake M5 |

Multi-gear, AI monitoring |

Quick tips for picking a fast 3D printer:

- Pick a strong motion system and frame.

- Choose a high-flow hotend and smart firmware.

- Change slicer settings to fit your needs.

- Make sure speed does not hurt print quality.

Check out SOVOL SV08 to see how experts build great printers.

FAQ

What makes CoreXY better for fast 3D printing?

CoreXY keeps the bed still and moves the print head quickly. You get less vibration and more accurate layers. This system works well with linear rails and Klipper firmware. You see faster prints and better quality.

How does Klipper firmware improve speed and reliability?

Klipper firmware uses a Raspberry Pi to process commands quickly. You get smoother motion and fewer errors. Input shaping reduces shaking. Your printer works faster and keeps prints strong.

Why do I need a high-flow hotend for speed?

A high-flow hotend melts and pushes more filament. You finish prints faster. This hotend works best with strong extruders and smart cooling. You get reliable results at high speed.

What role does cooling play in fast 3D printing?

Cooling keeps each layer solid and prevents sagging. Good cooling works with high-flow hotends and fast motion systems. You see sharper details and fewer print failures.

Can I use bigger nozzles for faster prints?

Yes, bigger nozzles lay down more material. You finish prints quickly. You may lose some fine details. Balance nozzle size with layer height and motion speed for best results.