You want to choose a 3d printer that matches your goals and projects. With so many 3d printers like the Sovol SV08 Max 3D Printer, Sovol SV08 3D Printer, and Sovol Zero 3D Printer, finding the right 3d printer can feel overwhelming. Think about what you need from 3d printing before you start shopping.

Tip: Make a list of your most important project requirements. This step helps you focus on features that matter most.

Key Takeaways

- Define your needs before shopping. Consider if you need a printer for personal projects or professional use. This decision shapes your expectations and required features.

- Evaluate print technology options. FDM printers are great for durable parts, while resin printers excel in high-detail models. Choose based on your project requirements.

- Assess your available space. Ensure you have enough room for the printer and post-processing tasks. Consider ventilation and access to power outlets.

- Set a realistic budget. Factor in not just the printer cost but also ongoing expenses like materials and maintenance. This helps avoid surprises later.

- Research and read reviews. User feedback provides valuable insights into printer performance and reliability. This helps you make an informed decision.

Define Your Needs

Personal vs. Professional Use

You should first decide if you need a 3d printer for personal or professional use. This choice shapes your expectations and the features you require. Personal users often want to create household items, educational projects, or custom figurines. Professionals usually need 3d printers for prototyping, product demos, or communicating complex ideas with physical models.

|

Setting |

Common Use Cases |

|---|---|

|

Personal |

Creating household items, educational projects, custom figurines |

|

Professional |

Prototyping, product demos, communication of complex ideas |

Tip: Think about how often you plan to use your printer and the level of detail you expect in your prints.

Types of Projects

The types of projects you plan to tackle will influence your choice. Some users focus on simple models or toys, while others need to produce functional parts or detailed miniatures. You should define your intended application, such as making prototypes, tooling, or production parts. Material choice also matters. Some projects require strong, flexible, or heat-resistant materials. Changing materials can add costs and require recalibration.

|

Criterion Number |

Criterion Name |

Description Summary |

|---|---|---|

|

1 |

Application |

Define your intended use (prototypes, tooling, production parts) |

|

4 |

Material |

Consider physical properties, material changeover costs, recalibration |

|

8 |

Post-processing |

Assess finishing needs, space, tools, labor, and safety equipment |

Space Considerations

You need to assess your available space before buying a 3d printer. Some models fit on a desktop, while others need a dedicated workbench or even a separate room. Consider ventilation, noise, and access to power outlets. Post-processing tasks, such as cleaning or curing prints, may require extra space and safety equipment. Planning your workspace ensures a smoother 3d printing experience.

Choosing a 3D Printer: Key Factors

When choosing a 3d printer, you must evaluate several key factors. Each factor influences your experience and the results you achieve. Matching printer features to your specific needs ensures you get the most value from your investment.

Print Technology (FDM vs. Resin)

You will encounter two main print technologies: FDM and resin. FDM printers extrude melted thermoplastic, while resin printers cure photosensitive resin with UV light. The choice between these technologies depends on your intended application and desired output quality.

|

Feature |

FDM |

SLA (Resin) |

|---|---|---|

|

Printing Process |

Extrudes melted thermoplastic |

Cures photosensitive resin with UV light |

|

Material Versatility |

Wide range of filaments (e.g., PLA, Kevlar) |

Limited to resin types, often brittle |

|

Output Quality |

Lower resolution, less detail |

High resolution (as small as 25 microns) |

|

Best Applications |

Prototypes, industrial tools, fixtures |

Presentation models, complex geometries |

|

Mechanical Strength |

Stronger materials available (e.g., polycarbonate) |

Generally weaker, suitable for delicate structures |

FDM printers suit users who need durable parts and material versatility. Resin printers excel at producing high-resolution models with intricate details. Consider your project requirements before selecting a technology.

Print Quality

Print quality determines how well your 3d printer produces accurate and detailed objects. You should pay attention to several measurable standards:

- Resolution: Measured in microns, includes XY resolution (horizontal detail) and Z resolution (layer height).

- Layer Height: Lower values lead to smoother surfaces and finer detail.

- Calibration: Proper bed leveling and extruder calibration are essential for accuracy.

- Material Quality: Consistent properties in filaments or resins improve print results.

- Print Speed and Cooling: Optimal settings balance quality and efficiency.

- XY Resolution defines the smallest movement of the print head on the X and Y axes.

- Z Resolution typically ranges from 50 to 200 microns (0.05 to 0.2 mm) for a good balance of quality and speed.

A higher XY resolution allows for finer details on the print's surface. A lower Z resolution results in smoother vertical aspects of the print. You should select a printer that meets your expectations for resolution and overall quality.

Tip: If you plan to print miniatures or presentation models, prioritize high resolution and precise calibration.

Ease of Use

Ease of use affects how quickly you can start printing and how much time you spend troubleshooting. Look for features such as intuitive interfaces, clear setup instructions, and reliable software. Some 3d printers offer touchscreen controls, automatic bed leveling, and guided calibration routines. These features help beginners and professionals alike save time and reduce frustration.

You should also consider the learning curve. If you are new to 3d printing, choose a model with strong community support and comprehensive documentation. Experienced users may prefer advanced features that allow for customization and fine-tuning.

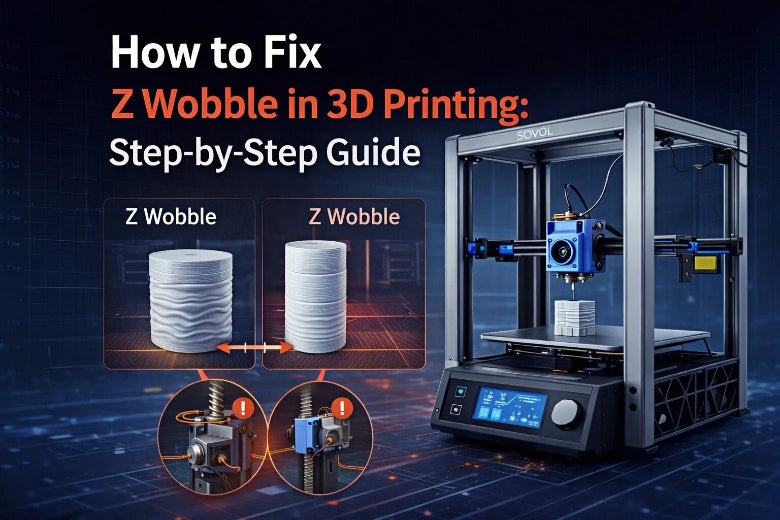

Maintenance Needs

Regular maintenance keeps your 3d printer running smoothly and ensures consistent print quality. You should perform weekly or bi-weekly checks if you use your printer extensively. Inspect for loose nuts, dust buildup, and verify belt tension. Monthly checks include basic cleaning and lubrication of moving parts. Quarterly reviews involve software updates and deeper cleaning.

- Clean fans to prevent overheating.

- Check belt tension for precise movements.

- Use compressed air or a soft brush to clean dust from electronics and ventilation areas.

- Inspect spool holders and couplers for wear or damage.

- Clear scratches from the build surface for good adhesion.

- Document parts replaced or adjustments made during maintenance.

Maintaining a clean nozzle is crucial for optimal print quality. Signs of a clogged nozzle include irregular filament extrusion or burn marks. Regularly checking and cleaning the nozzle prevents these issues. Proper belt tension is essential for longevity and performance. Belts that are too tight can stress components, while loose belts can lead to print quality problems.

Budget

Budget plays a major role in choosing a 3d printer. Entry-level models cost between $200 and $1,000. Mid-range printers range from $1,000 to $3,000. Professional machines can reach $10,000.

|

Category |

Price Range |

|---|---|

|

Entry-Level |

$200 – $1,000 |

|

Mid-Range |

$1,000 – $3,000 |

|

Professional |

$3,000 – $10,000 |

You should set a realistic budget based on your needs and expected usage. Entry-level printers suit hobbyists and beginners. Mid-range models offer better print quality and more features for serious enthusiasts. Professional printers deliver high resolution, advanced features, and robust build quality for demanding applications.

Note: Consider ongoing costs such as materials, replacement parts, and maintenance supplies when planning your budget.

By evaluating these key factors, you can make an informed decision when choosing a 3d printer. Focus on the features that align with your projects and quality expectations.

3D Printers: Features to Compare

Build Volume

When you compare 3d printers, build volume stands out as a key factor. A larger build volume lets you create bigger objects in one piece, which is essential for projects like furniture or industrial parts. You can also print multiple items at once, making small batch production more efficient. Printers with dimensions such as 500x500x500mm or greater are common in industries like architecture and automotive, where large models are required.

- A bigger build volume supports larger single-piece projects.

- You can print several objects simultaneously, saving time.

- Large-format printers suit industries needing oversized prototypes.

Material Compatibility

You should check which print materials a 3d printer supports before making a decision. The most popular 3d printers work with a range of materials, each suited for different applications. Plastic remains the most common choice due to its versatility and cost-effectiveness. FDM printers use thermoplastic filaments, shaping them layer by layer.

|

Material |

Compatibility |

Applications |

|---|---|---|

|

PLA |

FDM |

Prototyping, general use |

|

ABS |

FDM |

Functional parts, durable models |

|

PETG |

FDM |

Functional, moisture-resistant parts |

|

Nylon (PA12) |

SLS |

Strong prototypes, industrial applications |

|

PEEK |

FDM |

High-performance parts, heat resistance |

|

Carbon Fiber Composites |

FDM |

Strong, lightweight parts |

- PLA is biodegradable and easy to print, making it ideal for beginners.

- ABS offers better heat resistance but needs a controlled environment.

- PETG combines strength and flexibility, and resists moisture.

- Nylon provides high strength and chemical resistance, often used in SLS printing.

Print Speed & Accuracy

Print speed and accuracy affect how quickly you finish projects and the quality of your results. FDM printers usually take 3–8 hours to print a 10 cm tall object, while resin printers finish in 2–5 hours. Resin printers deliver excellent detail and smooth surfaces, with minimum feature sizes around 0.1 mm. FDM printers show visible layers and have minimum feature sizes near 0.2 mm.

|

Aspect |

FDM Printer |

Resin Printer (LCD/DLP/SLA) |

|---|---|---|

|

Print time for 10 cm tall object |

3–8 hours |

2–5 hours |

|

Detail |

Good |

Excellent |

|

Print quality |

Visible layers |

Smooth, fine detail |

|

Dimensional Tolerance (Typical) |

±0.5% (±0.5 mm over 100 mm) |

±0.15% to ±0.2% (±0.01 mm for 100 mm) |

|

Minimum Feature Size |

~0.2 mm |

~0.1 mm |

Software & Connectivity

You need reliable software and connectivity to manage your 3d printer efficiently. Many platforms offer remote monitoring, control, and advanced features. OctoPrint provides an open-source web interface for remote control and live camera feeds. Mainsail and Fluidd deliver lightweight, customizable interfaces for Klipper firmware. Cloud-based management software, such as SimplyPrint and Obico, enables remote printing and AI-powered failure detection.

|

Software Platform |

Description |

|---|---|

|

3D Printer Operating System and Management Software |

Cloud-based management software that connects 3D printers, users, and data on one platform. |

|

Obico |

Remote monitoring and management platform for 3D printing with features like real-time video streaming and AI-powered failure detection. |

|

OctoPrint |

Open-source web interface for 3D printers, offering remote control and live camera feed monitoring. |

|

Mainsail |

Lightweight web interface for Klipper with remote control and advanced print monitoring features. |

|

Fluidd |

Customizable web interface for Klipper, focusing on user experience and functionality. |

|

SimplyPrint |

Cloud management software allowing remote printing and AI failure detection. |

Safety Features

Safety features protect you and others when using 3d printers at home or in educational settings. You should select a fully enclosed printer to reduce exposure to hot surfaces and emissions. Using pla filament lowers emissions and improves air quality. Good ventilation, such as six air changes per hour, is important. Place the printer away from desks and near a fire extinguisher. Combine HEPA and carbon filters for better air quality, and post safety reminders near the printer.

Tip: Always check for proper grounding and keep safety equipment nearby when operating your 3d printer.

Compare 3D Printer Types

FDM vs. Resin

When you compare FDM and resin 3d printers, you notice clear differences in performance and best use cases. FDM printers use thermoplastic filaments, which melt and layer to form objects. Resin printers use liquid resin, which cures with UV light to create detailed models. If you want to print large, single items, FDM works best. Resin printers excel at producing many small, intricate pieces in one batch. The print time for FDM increases with each object, but resin printers maintain a steady print time if all models fit on the build plate.

|

Batch Printing Aspect |

FDM Printer |

Resin Printer |

|---|---|---|

|

Increases with each object |

Stays about the same if objects fit |

|

|

Efficiency |

Lower for batches |

Very high for batches |

|

Best use |

Large, single prints |

Many small, detailed prints |

You should choose FDM for projects that require strong, versatile materials and larger parts. Resin printers suit you if you need high detail and want to print several small models at once.

Open vs. Enclosed

You must decide between open-frame and enclosed 3d printers based on your workspace and safety needs. Open-frame models expose moving and hot parts, which can pose risks. Enclosed printers provide a physical barrier, improving safety and controlling environmental factors. Enclosed designs maintain stable temperatures and reduce fumes, which helps with print quality and layer adhesion.

|

Feature |

Open-Frame Printers |

Enclosed Printers |

|---|---|---|

|

Safety |

Less safe; lacks physical barriers for protection |

Safer; provides a barrier against hot and moving parts |

|

Print Quality |

Sensitive to environmental conditions; may warp prints |

Superior reliability; reduces print failures and improves layer adhesion |

|

Environmental Control |

Requires controlled room conditions for best results |

Maintains stable temperatures; controls fumes and odors |

Tip: If you work with advanced materials or print in shared spaces, enclosed printers offer better safety and reliability.

Kits vs. Pre-Assembled

You can select kit-based or pre-assembled 3d printers depending on your technical skills and budget. Kit-based printers cost less and give you full control over upgrades and features. You must assemble these printers yourself, which requires patience and technical knowledge. Pre-assembled models arrive ready to use, saving you time and effort, but they often cost more and offer less flexibility for customization.

|

Aspect |

Kit-Based Printers |

Pre-Assembled Printers |

|---|---|---|

|

Cost |

Typically more expensive |

|

|

Control |

Full control over features and upgrades |

Limited control over features |

|

Assembly Requirement |

Requires assembly and technical knowledge |

Ready to use out of the box |

You should choose a kit if you enjoy building and want to learn about 3d technology. Pre-assembled printers suit you if you prefer convenience and want to start printing right away.

How to Choose a 3D Printer on a Budget

Entry-Level vs. Premium

You need to compare entry-level and premium 3d printers before you decide how to allocate your budget. Entry-level models offer basic features and suit hobbyists or beginners. Premium printers deliver advanced capabilities, higher accuracy, and better reliability. The price difference can be significant, so you must weigh the long-term value against your immediate needs.

|

Type of Printer |

|

|---|---|

|

Hobbyist |

$200 – $1,500 |

|

Enthusiast 3D Printers |

$1,000 – $4,000 |

|

Professional/Performance 3D Printers |

$4,000 – $20,000 |

|

Enterprise 3D Printers |

$20,000 – $100,000 |

If you want to choose a 3d printer for personal projects, a hobbyist or enthusiast model may offer the best value for your budget. Professional and enterprise printers suit users who need top-tier performance and reliability for demanding applications. You should always consider how much you plan to print and the types of materials you want to use. Premium printers often support a wider range of materials and deliver better results, but entry-level models can provide excellent value for simple tasks.

Hidden Costs

When you set your budget, you must look beyond the sticker price. Owning a 3d printer involves several hidden costs that can affect your total investment and long-term value.

- Production costs are just the beginning; other hidden costs include quality, reliability, and flexibility.

- Supply chain costs can be significant, including shipping, customs delays, and the need for decentralized production strategies.

- Consequential costs arise from unforeseen issues, such as breakdowns, which can severely impact profitability.

- Ongoing material and maintenance costs are crucial in determining the total cost of ownership for 3d printers.

- High costs from proprietary materials can significantly inflate operating expenditures, leading to a poor return on investment.

- Key cost categories include:

- Materials: Costs vary based on supplier and can be significantly marked up by manufacturers.

- Labor: Includes costs related to machine setup, cleaning, and post-processing.

- Process Consumables: Costs for additional components and supplies needed for operation.

- Maintenance: Regular hardware replacements and warranty costs can add to overall expenses.

- Closed materials systems can lead to excessive pricing, increasing total ownership costs and reducing ROI.

You should factor in these expenses when you choose a 3d printer. A realistic budget helps you avoid surprises and ensures you get the best value for your money. Careful planning leads to better results and supports your 3d printing goals.

Making Your Final Choice

Research & Reviews

You should start your final decision process by reading reviews and user feedback. Reliable sources include community-driven platforms where users share personal experiences with different 3d printers. These platforms offer diverse opinions and real-time feedback, helping you understand how each model performs in actual use. You gain insight into common strengths and weaknesses, which helps you avoid costly mistakes.

- Users discuss their hands-on experiences with various models.

- You see a range of opinions and troubleshooting tips.

- Community platforms provide up-to-date feedback on new releases.

Community Support

Active community support makes a big difference when you own a 3d printer. You can find guides that outline common issues and solutions, often created by experienced users. These guides help you resolve problems quickly and optimize your printing results. You may seek advice on software settings or hardware upgrades from communities like the SketchUp Community. This collaborative environment encourages problem-solving and knowledge sharing.

- Guides list frequent 3d printing issues and solutions.

- Users offer advice on improving print quality and optimizing settings.

- Communities foster teamwork and help you learn new techniques.

You can join active online communities to stay connected. For example:

|

Activity Level |

|

|---|---|

|

PrusaPrinters |

High |

|

Now known as |

printables.com |

Where to Buy

You should purchase your 3d printer from reputable retailers to ensure quality and support. Trusted sellers offer clear warranty terms and comprehensive protection. You can compare options using the table below:

|

Website Link |

|

|---|---|

Warranty coverage varies by region and seller. For example:

|

Region |

Warranty Period |

Coverage Details |

|---|---|---|

|

EU Consumers |

2 years |

Covers all parts, excludes user error and maintenance issues. |

|

EU Enterprises |

1 year |

Covers all parts, excludes user error and maintenance issues. |

|

Rest of the World |

1 year |

Covers all parts, excludes user error and maintenance issues. |

You should look for sellers that offer comprehensive parts and labor protection, unlimited claims, and international coverage. Some plans cover major manufacturers and must be purchased within 30 days of your original purchase.

Tip: Always review warranty details before buying to protect your investment in 3d technology.

You can make a smart choice by following these steps:

- Define your needs and main application.

- Research technologies and compare models.

- Evaluate features like build volume, material compatibility, and accuracy.

- Use a checklist and read reviews before deciding.

Focus on features that fit your space and project goals. Advanced customization, cloud-based access, and security matter for many users. Remember, the best 3d printers help you achieve your 3d project vision.

FAQ

What is the best 3d printer for beginners?

You should choose a model with easy setup, strong community support, and reliable print quality. Entry-level 3d printers often include guided calibration and user-friendly interfaces. These features help you start printing quickly and reduce troubleshooting time.

How often should I maintain my 3d printer?

You should perform basic maintenance weekly. Clean the nozzle, check belt tension, and inspect moving parts. Regular care prevents print failures and extends your printer’s lifespan.

Can I use different materials with my 3d printer?

You can use various materials if your printer supports them. Check the manufacturer’s specifications. Some printers handle only specific filaments or resins, while others offer broader compatibility for advanced projects.

Do I need special software to design 3d models?

You need 3d modeling software to create custom designs. Many free and paid options exist, such as Tinkercad or Fusion 360. Most printers also require slicing software to prepare files for printing.