You can stop 3d printer layer shifting by looking at your printer often and making small changes. Layer shifting happens when layers do not line up right during printing. This can lead to problems like:

- Prints that look crooked or have steps

- Objects that are not as strong

- Bad print quality

Begin with easy checks to get better prints.

Key Takeaways

- Check your printer's belts and pulleys often. This helps stop layer shifting. Belts that are tight move the printer parts correctly.

- Set up your printer settings like speed and acceleration. This helps prints look better. It also lowers the chance of layers not lining up.

- Put your printer on a flat and steady table. Keep it away from things that shake. This helps layers stay lined up while printing.

What Is 3D Printer Layer Shifting?

Layer Shifting Explained

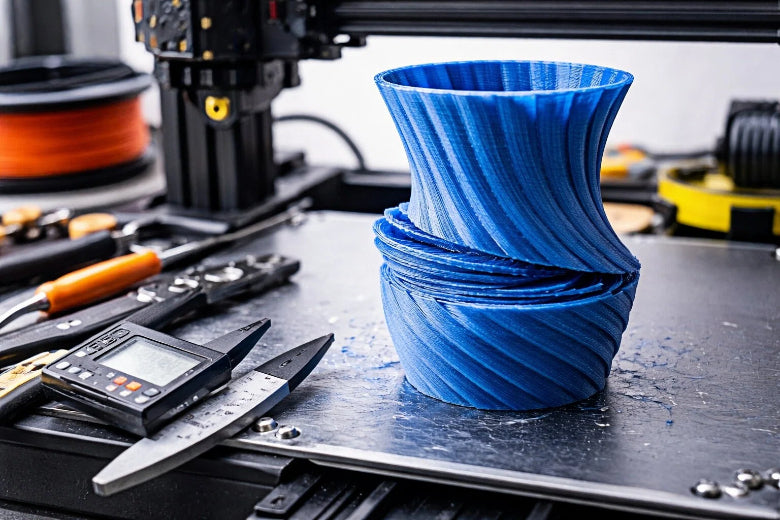

Sometimes your 3D prints look slanted or have steps on the sides. This is called 3D printer layer shifting. It happens when the layers do not match up right. The printer head moves to the wrong spot. Then, each new layer prints in the wrong place.

3D print layer shift means the layers are not lined up right. The print can move sideways or up and down while printing. This can happen for many reasons. Some reasons are problems with the printer parts, software errors, or things like shaking or bumps during printing.

You can find layer shifting by looking for these things:

- A sudden sideways move in the layers that stays for the rest of the print.

- Layers that stick out, making the print look slanted or rough.

- Gaps in the lower layers, which look like steps on the sides.

- The print surface moves or the layers on top do not match the ones below.

Why It Matters

Layer shifting can mess up your print and waste your time. If the layers do not line up, your object may not fit or work right. Even small shifts can make a part weak or broken. If you want your prints to be strong and correct, you must stop layer shifting. This is very important for parts that need to be exact or hold weight. You can stop these problems by checking your printer often and making sure it works well.

Common Causes of Layer Shifting

Mechanical Problems

Mechanical issues are the most common reason for 3d printer layer shifting. You should check for loose belts, misaligned pulleys, and dirty rods. If a belt is loose or worn, it can skip teeth and cause the print head to move the wrong way. Misaligned pulleys can slip, making layers print in the wrong spot. Dirty or blocked axles and rods can make the printer move unevenly. Use this table to help you spot common mechanical problems:

|

Cause Description |

|---|

|

Stiff or blocked axles; check bearings for smooth movement. |

|

Loose pulley on the motor shaft causing backlash. |

|

Excessive motor power; check and adjust belts. |

|

Dirty rods; clean and oil rods often. |

|

Loose screws or bolts causing play in the extruder. |

Speed and Acceleration

High print speeds can shake your printer and make the motors skip steps. If you set acceleration or jerk too high, the print head may move too fast and shift layers. Lowering speed and acceleration is one of the common solutions for layer shifting issues.

Motor and Electronics

Problems with stepper motors or their drivers can cause layer shifting. A bad connection or a malfunctioning driver can make the motor skip steps. You should check all cables and make sure the drivers work well.

Slicer and Firmware

Wrong slicer or firmware settings can lead to layer shifting. If you see oval holes or misaligned rods, check your calibration and make sure all parts are tight. Blocked nozzle paths can also cause shifts.

Environmental Factors

Vibrations from nearby machines or an unstable table can move your printer during a print. Temperature changes can cause motors to overheat and skip steps. Place your printer on a stable surface and keep it away from heavy equipment.

By understanding these causes, you can prevent most layer shifting issues and improve your print quality.

Mechanical Checks to Prevent Layer Shifting

Mechanical checks help you stop 3d printer layer shifting before it ruins your prints. You can follow these steps to keep your printer working well and avoid layer shifting. Regular maintenance makes your printer last longer and gives you better results.

Inspect Belts and Pulleys

Belts and pulleys move the print head and bed. If they slip or wear out, your layers will not line up. You should check belts and pulleys often. Here is a simple way to check and tighten belts:

- Look at the X and Y belts. They should feel firm but not too tight. Pluck each belt gently. You should hear a low twang, not a high pitch.

- Check for loose or worn belts and pulleys. If you see cracks or fraying, replace the belt.

- Tighten the eccentric nuts on the rollers for the X and Y axes. This helps the rollers grip the rails.

- Make sure the belt tension knobs are secure. These knobs can loosen over time.

- Check the set screw on the Y-axis motor pulley. It should be firmly attached to the motor shaft.

Tip: If you notice any slipping or strange noises, stop the printer and check belts and pulleys right away. This is one of the most important maintenance tips.

You should check belts and pulleys every month. This simple step helps prevent layer shifting and keeps your printer running smoothly.

Check Linear Bearings

Linear bearings help the printer move smoothly. If they get dirty or dry, the print head can jerk or stop. You should lubricate and clean motion parts to keep everything moving well.

- Wipe the rods and bearings with a clean cloth.

- Add a small drop of machine oil to each bearing.

- Move the print head by hand to spread the oil.

If you hear grinding or feel rough spots, clean the rods again. You should check bearings every few weeks. Clean bearings help you avoid layer shifting and make your prints look better.

Tighten Frame and Screws

A loose frame can cause the printer to shake and shift layers. You need to secure bed and frame by tightening all screws and bolts. Use a screwdriver or wrench to check each screw.

- Check the tightness of bolts on the frame. If you find any loose bolts, tighten them until they feel snug.

- Make sure there are no gaps or misalignments in the printer’s structure.

- Pay attention to factory-installed bolts. Sometimes they are not tight enough.

Note: Proper torque helps prevent gaps and keeps your printer stable. This is a key maintenance tip for every printer owner.

You should check the frame and screws every two months. A strong frame helps you avoid layer shifting and keeps your printer safe.

Maintain Belt Tension

Belt tension affects how well your printer moves. If the belts are too loose or too tight, you may see layer shifting. You should check and tighten belts to keep tension in the right range.

- For the X-axis, aim for a tension of about 250.

- For the Y-axis, aim for a tension of about 275.

- The best range is plus or minus 15 from these numbers.

- If the tension is below 240, loosen the belt.

- If the tension is above 290, tighten the belt.

You can use a belt tension gauge or a simple app to measure tension. Always check and tighten belts after moving your printer or finishing a big print.

Tip: Good belt tension helps with calibration and keeps your prints accurate. Add this step to your regular maintenance tips.

By following these mechanical checks, you can prevent 3d printer layer shifting and get better results. Regular maintenance and simple checks help you avoid problems and save time. Remember to check belts and pulleys, lubricate and clean motion parts, secure bed and frame, and keep belt tension in the right range. These steps make your printer last longer and improve your print quality.

Calibrate Printer for Better Results

Printer Calibration Steps

You can prevent misaligned layers by taking time to calibrate your printer. Calibration helps your printer move smoothly and print each layer in the right place. Use these steps to get better results:

|

Description |

|

|---|---|

|

Reduce the Printing Speed |

Keep the speed below 60mm/s to stop the motors from skipping or overheating. |

|

Reduce the Travel Speed |

Set travel speed to 100-150mm/s to avoid sudden impacts. |

|

Adjust the Retraction |

Increase retraction distance to stop blobs and oozing. |

|

Enable the Z hop |

Lift the printhead before moving to prevent bumps. |

|

Disable Combing mode |

Turn off combing for large prints to avoid the printhead hitting the model. |

|

Set the right belt tension |

Make sure belts are tight so motors can move the printhead correctly. |

|

Identify the direction of shifts |

Look at which way the layers move to help find the problem. |

Tip: Always check your printer’s manual for the best speed and tension settings.

Test and Adjust Alignment

After you calibrate printer settings, test the alignment to catch any issues early. You can follow these simple steps:

- Inspect belts and tighten them if they feel loose.

- Check pulleys and make sure they are secure on the motor shafts.

- Keep your printer clean and add a drop of oil to moving parts.

- Level the bed and check motor settings often.

- Place your printer on a stable table to stop vibrations.

- Lower print speed if you see any shifting.

Regular calibration and maintenance help you avoid layer shifting and keep your prints looking great.

Adjust Print Settings to Prevent Layer Shifting

You can prevent layer shifting by changing a few print settings in your slicer. These steps help your printer move smoothly and keep each layer in the right spot. Follow these tips to get better results and avoid problems.

Lower Print Speed

Print speed affects how well your printer can keep up with each movement. If you print too fast, the motors may skip steps and cause layers to shift. You should start with the recommended speeds for your material. Here is a table to help you choose the right speed:

|

Material |

Recommended Print Speed |

|---|---|

|

ABS |

40-60 mm/s |

|

PETG |

Up to 60 mm/s |

|

TPU |

15-30 mm/s |

You can set the speed in your slicer software. If you see shifting, lower the speed by 20-50%. Use the default profile for your material as a starting point. Slow speeds help your printer stay accurate.

Reduce Acceleration

Acceleration controls how quickly your printer changes direction. High acceleration can shake the printer and cause layer shifting. You should lower the acceleration and jerk settings for the X and Y axes. In your slicer, look for these options:

- Set acceleration to a lower value, such as 500-1000 mm/s².

- Reduce jerk settings to help the printer move smoothly.

Tip: Lowering acceleration makes your printer less likely to skip steps. This is a simple way to improve print quality.

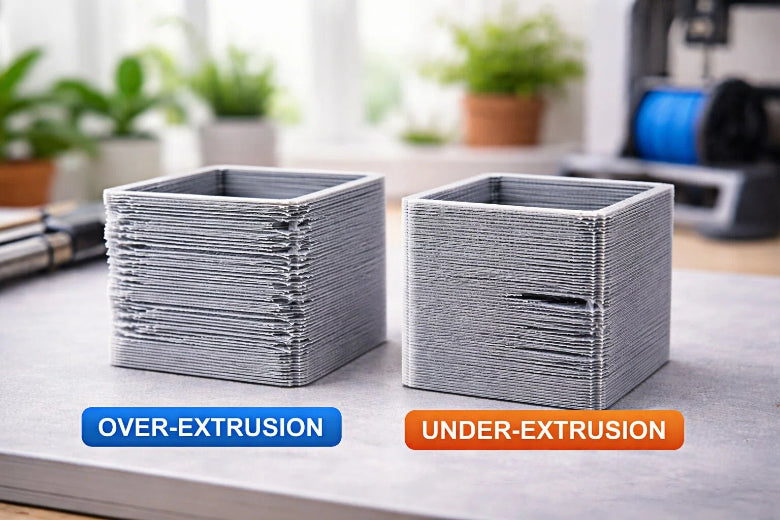

Decrease Extrusion Rate

Too much filament can push the print head out of place. You should decrease the extrusion rate if you see blobs or rough edges. In your slicer, find the flow or extrusion multiplier setting. Lower it by 5-10% and test your print. This step helps with calibration and keeps layers lined up.

Regular maintenance and careful adjustment of these settings help you avoid layer shifting. Always check your printer after making changes and run a small test print to see the results.

Electronics and Motor Troubleshooting

Check Stepper Drivers

Stepper drivers control how your printer’s motors move. If a driver fails, you might see layer shifting or missed steps. You should check the drivers during regular maintenance. Look for blinking lights or error codes on the control board. If you hear clicking or grinding sounds, turn off the printer and inspect the drivers. Make sure each driver sits firmly in its socket. If you find a loose driver, gently press it back into place. Replace any driver that shows damage or burns.

Tip: Always unplug your printer before touching any electronics. This keeps you safe and protects your printer.

Prevent Overheating

Motors and electronics can get hot during long prints. Overheating causes motors to skip steps and shift layers. You can prevent this by following these steps:

- Test the cooling fan to make sure it works well.

- Increase the fan’s speed if you notice heat building up.

- Use a high-quality hot end to reduce heat creep.

- Choose better-quality filament for steady printing.

- Boost print speed to keep filament moving.

- Lower the printing temperature to control heat.

You should check these steps before starting a long print. Good calibration and cooling help your printer run smoothly.

Inspect Wiring

Loose or damaged wires can cause sudden stops or shifts. You should inspect all cables and connectors as part of your troubleshooting routine. Look for frayed wires or loose plugs near the motors and control board. Gently tug each wire to check if it stays in place. If you find a broken wire, replace it before printing. Secure all cables with clips or ties to prevent movement during a print.

Note: Careful wiring checks help you avoid problems and keep your printer working well.

Slicer and Firmware Settings

Update Firmware

It is important to keep your printer’s firmware current. New firmware can fix problems and add helpful features. These updates help stop layer shifting. First, go to your printer’s brand website. Look for the newest firmware version. Download it and follow the steps to install. Updated firmware helps with calibration and slicer settings. This makes your prints more exact. If you see layer shifting after a power loss or error, new firmware may help your printer finish the print.

Tip: Set a reminder to check for updates every few months. This easy step helps with maintenance and troubleshooting.

Review Slicer Configuration

Slicer software tells your printer how to build each layer. You can change slicer settings to help stop layer shifting. This is very useful for tricky prints. Here is a table with important settings:

|

Setting |

Description |

Recommended Value |

|---|---|---|

|

Retract Speed |

How fast the build plate lowers after each layer. |

150–400 mm/min |

|

Rest Time After Retract |

How long the build plate waits after moving down. |

0.5 to 1 second |

|

Lift Height |

How far the build plate moves up between layers. |

10 mm for bottom layers, 7 mm normal |

You can find these settings in your slicer software. Change each one and do a test print. If you see shifting, lower the retract speed or make the rest time longer. Good slicer settings help your printer work better.

Enable Power Recovery

Power loss can mess up a print and shift layers. You can turn on power recovery in your printer’s firmware. This feature lets your printer save its spot if power goes out. When power comes back, the printer heats up and goes to the last spot. The print starts again from where it stopped. This keeps layers lined up. Look in your printer’s menu for power recovery options. Turn them on before starting a long print.

Note: Power recovery saves filament and keeps your prints strong.

By updating firmware, checking slicer settings, and turning on power recovery, you can stop layer shifting and make your prints better. Regular checks and fixes help your printer work well.

Environmental and External Factors

Outside things can make your 3D printer shift layers. This can happen even if your settings are good. You can stop many problems by watching your workspace. Make a few easy changes to help your printer.

Stable Surface

Your printer needs to sit on something strong. If the table shakes, your printer can move. This can mess up your print. Try these tips to keep your printer steady:

- Put your printer on a heavy desk or workbench.

- Make sure the build plate is flat and does not move.

- Use a level tool to check the build plate.

- Place dampening pads under your printer to stop shaking.

- Check the build plate and frame often for problems.

A strong table helps your printer stay still. This keeps each layer in the right place.

Minimize Vibrations

Vibrations can make your printer shift layers. You can stop vibrations by:

- Keeping your printer away from big machines or busy spots.

- Using dampening pads under your printer.

- Putting your printer on a strong table.

- Checking moving parts often and fixing them.

These steps help your printer move smoothly. Your prints will look better.

Control Room Temperature

Changes in room temperature can hurt your printer. If it gets too hot or cold, printer parts can change size. This can make the print head move wrong and shift layers. You can:

- Keep the room at the same temperature while printing.

- Do not put your printer near windows or heaters.

- Check your printer settings if you see shifting when the weather changes.

A steady room temperature helps each layer line up right.

Avoid Power Interruptions

Power problems can stop your print and shift layers. You can use backup power to protect your prints:

|

Solution Type |

Advantages |

Limitations |

|---|---|---|

|

UPS Systems |

Keeps power steady, helps avoid sudden stops. |

Needs battery changes sometimes. |

|

Portable Power Stations |

Easy to move, works with solar charging. |

Costs more and takes up space. |

|

DIY Battery Backup |

You can build it for your needs. |

Needs some technical skill. |

Power loss can make layers uneven and cause surface problems. You can stop these problems by using backup power. Check your troubleshooting steps if you see shifting.

If you keep your printer on a strong table, stop vibrations, keep the room temperature steady, and use backup power, you can stop most layer shifting from the environment. These easy steps, plus good settings and regular checks, help you get better prints every time.

Prevent Layer Shifting with Proper Supports

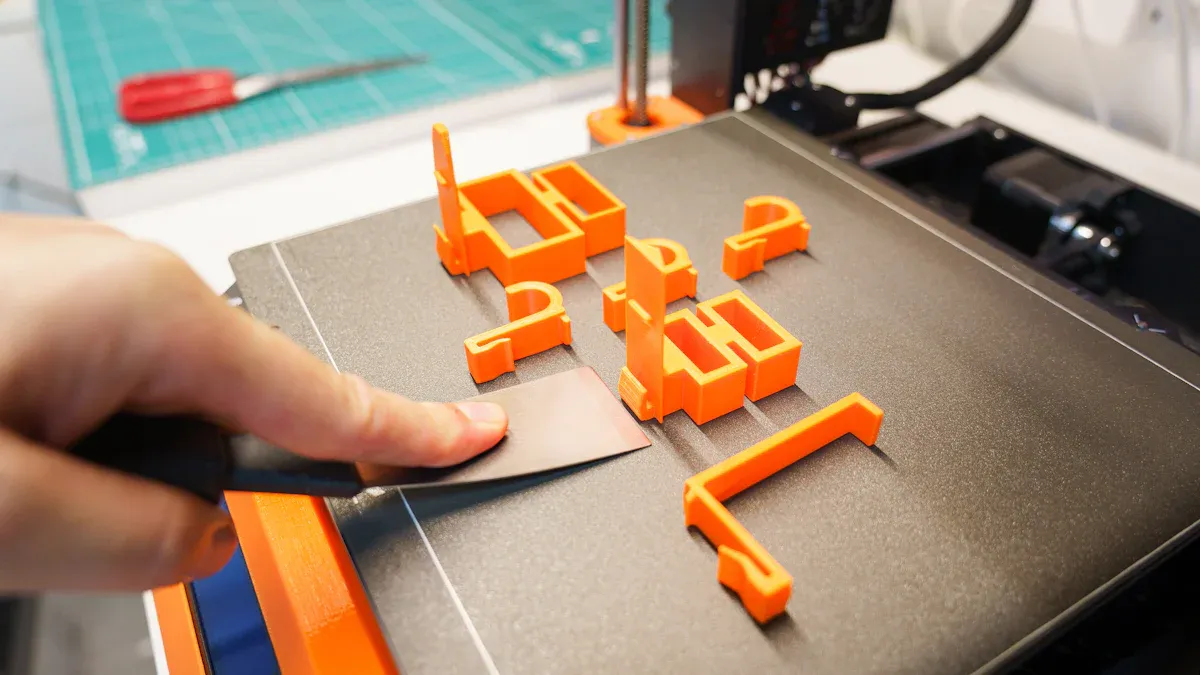

Correct Support Placement

You can stop layer shifting by placing supports in the right spots. Supports hold up parts of your print that hang in the air. If you put supports in the wrong place, your print may wobble or shift. Start by looking at your model in the slicer. Check which parts need extra help. Use the settings in your slicer to add supports under overhangs and weak spots. Try these steps:

- Open your slicer and load your model.

- Turn on support generation in the settings.

- Look for overhangs and mark them for support.

- Place supports close to the edges but not too far from the main part.

- Preview the print to see if supports touch all needed areas.

Tip: Good support placement helps with calibration and keeps your print steady.

Avoid Abnormal Suction Forces

Suction can pull layers out of place during printing. You can avoid this problem by changing a few settings and using the right supports. If your print has large flat areas, air can get trapped and cause suction. Try these steps:

- Use grid or tree supports instead of solid blocks.

- Add small holes in wide flat areas to let air escape.

- Lower the bed temperature if you see suction marks.

- Check your troubleshooting guide for suction problems.

|

Support Type |

Best Use |

How It Helps |

|---|---|---|

|

Grid |

Flat surfaces |

Stops suction |

|

Tree |

Complex shapes |

Reduces shifting |

You can keep your layers lined up by using proper supports and adjusting your settings. Regular calibration and careful troubleshooting help you get better prints.

You can stop 3d printer layer shifting by looking at your printer often. Use calibration to help your printer work better. Try these easy troubleshooting steps: check the belts, change print settings, and make sure your workspace is steady. When you learn new things, your prints get better. Keep asking questions and keep practicing.

FAQ

What should you do first if you notice layer shifting?

Check your printer for loose belts or screws. Tighten them if needed. Run a quick test print to see if the problem goes away.

How often should you perform calibration on your 3D printer?

You should perform calibration every month. This keeps your printer accurate and helps prevent layer shifting in future prints.

Can changing the print speed help stop layer shifting?

Yes. Lowering the print speed makes your printer move more smoothly. This reduces the chance of motors skipping steps and keeps layers lined up.