Professionals and hobbyists achieve the best results on the Sovol SV08 Max by selecting 3D print materials that match their project needs. Material choice directly impacts print quality, reliable quality, and overall performance. For example, PLA, ABS, and PETG each offer unique mechanical properties for 3D printing large or detailed models.

|

Property |

PLA |

ABS |

PETG |

|---|---|---|---|

|

Tensile Strength |

~4,600 psi |

~7,250 psi |

|

|

Elongation at Break |

6% |

20% |

20-30% |

|

Glass Transition Temp |

60-65°C |

~105°C |

85°C |

|

Printing Temperature |

200-220°C |

220-250°C |

220-260°C |

The Sovol SV08 Max’s advanced features, such as its CoreXY system, Smart Auxiliary Feeder, high-temp hotend, and large build volume, expand 3D printer compatibility and maximize print quality. These features ensure the printer delivers high-quality 3D printing for a wide range of materials and applications.

Key Takeaways

- The Sovol SV08 Max supports many 3D print materials like PLA, ABS, PETG, TPU, and specialty filaments, allowing users to choose the best material for their project needs.

- Advanced features like the CoreXY system, high-temp hotend, and Smart Auxiliary Feeder help achieve high print quality, smooth filament flow, and reduce print failures.

- Proper print settings for each material, such as nozzle and bed temperatures, print speed, and cooling, are essential to get the best results with the Sovol SV08 Max.

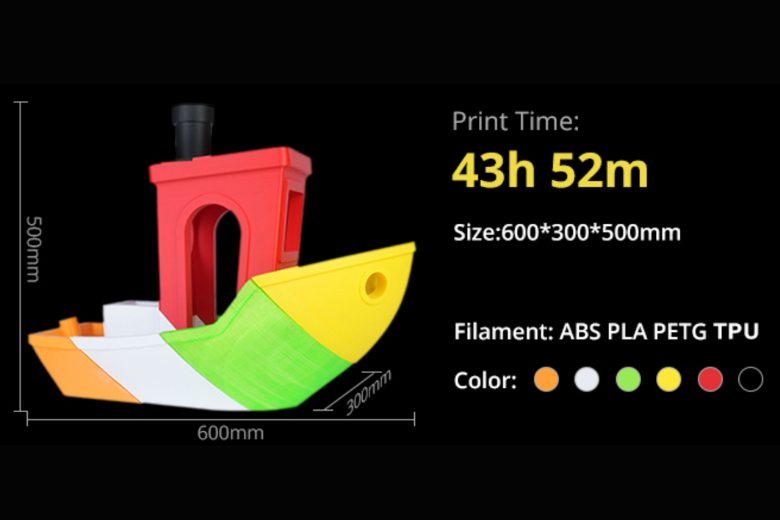

- The large 500×500×500 mm build volume lets users print big models, cosplay armor, industrial parts, and oversized designs in one piece, saving time and improving strength.

- Regular maintenance, cleaning, and careful material switching keep the printer running smoothly and ensure consistent, high-quality prints every time.

Material Overview

Sovol SV08 Max Compatibility

The Sovol SV08 Max stands out as a versatile 3d printer that supports a wide range of print materials. Users can rely on this printer for both standard and advanced 3d printing projects. The Sovol SV08 Max handles popular materials such as PLA, ABS, and PETG with ease. It also accommodates flexible filaments like TPU, engineering-grade options like PC and PA (nylon), and composite filaments including PETG-CF (carbon fiber reinforced). Specialty filaments, such as glow-in-the-dark or wood-filled, also work well with this 3d printer.

The Sovol SV08 Max’s compatibility with these materials comes from its advanced features. The high-temp hotend reaches temperatures suitable for demanding 3d print materials. The thick, heated aluminum bed ensures strong adhesion and reduces warping, even during large-scale printing. The Smart Auxiliary Feeder maintains smooth filament flow and detects tangles or clogs, which helps users achieve consistent print quality. These features allow professionals and hobbyists to explore new 3d printing possibilities and push the boundaries of their projects.

Tip: The Sovol SV08 Max’s large build volume enables users to print full-scale models and industrial parts in a single job, making material choice even more important for achieving the desired print quality.

3D Print Materials

The Sovol SV08 Max supports a broad spectrum of 3d print materials, each offering unique benefits for different applications. Below is an overview of the most common materials compatible with this 3d printer:

- PLA (Polylactic Acid): Easy to print, low warping, and ideal for prototypes or decorative models. PLA delivers reliable print quality and works well for beginners and professionals.

- ABS (Acrylonitrile Butadiene Styrene): Strong, impact-resistant, and suitable for functional parts. ABS requires higher temperatures, which the Sovol SV08 Max provides through its advanced hotend and heated bed.

- PETG (Polyethylene Terephthalate Glycol): Combines strength and flexibility. PETG resists moisture and chemicals, making it a popular choice for mechanical parts.

- TPU (Thermoplastic Polyurethane): Flexible and durable. TPU enables users to print gaskets, phone cases, and wearable items with the Sovol SV08 Max.

- PETG-CF (Carbon Fiber Reinforced PETG): Offers enhanced stiffness and strength. The Sovol SV08 Max’s robust feeder and high-temp hotend handle these abrasive filaments, ensuring consistent print quality.

- PC (Polycarbonate): High strength and heat resistance. PC is ideal for engineering applications and industrial prototypes.

- PA (Nylon): Tough and wear-resistant. PA suits gears, hinges, and moving parts that require durability.

- Composites and Specialty Filaments: The Sovol SV08 Max prints wood-filled, metal-filled, and glow-in-the-dark filaments, expanding creative options for users.

The Sovol SV08 Max’s advanced features, such as the high-flow nozzle and multi-fan cooling, further enhance print quality across all supported materials. These features help maintain optimal temperatures and prevent common 3d printing issues like stringing or layer separation. Users can confidently experiment with new materials, knowing the Sovol SV08 Max delivers reliable results and high-quality prints.

Note: Always check the filament manufacturer’s guidelines for recommended print settings. The Sovol SV08 Max’s robust design and advanced features give users the flexibility to fine-tune settings for each material, maximizing print quality and performance.

Print Settings

PLA and PETG

The Sovol SV08 Max delivers high precision and print accuracy with PLA and PETG. For PLA, users achieve optimal print quality by setting the nozzle temperature between 200°C and 220°C and the bed temperature at 55°C to 60°C. PETG requires a higher nozzle temperature, typically between 230°C and 250°C, and a bed temperature of 70°C to 80°C. The Sovol SV08 Max’s multi-fan cooling system ensures excellent surface finish and reduces stringing, especially for PLA. For PETG, users should keep the cooling fan off for the first few layers and then set it to 30-50% for the rest of the print. Print speeds between 30 and 60 mm/s work well for both materials, balancing print quality and accuracy. The thick aluminum bed provides strong adhesion, which is essential for large 3d prints. Adjusting the Z-offset and flow rate helps fine-tune print quality for different brands of filament.

|

Parameter |

PLA |

PETG |

|---|---|---|

|

Nozzle Temp |

200°C - 220°C |

230°C - 250°C |

|

Bed Temp |

55°C - 60°C |

70°C - 80°C |

|

Print Speed |

30 - 60 mm/s |

30 - 60 mm/s |

|

Cooling Fan |

100% after 1st layer |

0% (first layers), 30-50% (general) |

|

Retraction |

2-4 mm, 35-40 mm/s |

2-4 mm, 35-40 mm/s |

Tip: The Sovol SV08 Max’s advanced bed leveling technology ensures a perfect first layer, which is critical for print quality and strong adhesion.

ABS and PC

ABS and PC require higher temperatures and careful calibration for optimal print quality. The Sovol SV08 Max’s 1300W heated bed reaches 100°C quickly, providing even heat distribution for large 3d prints. Users should set the nozzle temperature to 240°C-260°C for ABS and 260°C-280°C for PC. The bed temperature should be 90°C-110°C for ABS and 100°C-120°C for PC. The printer’s corexy motion system maintains accuracy and precision at high speeds, supporting demanding 3d printing projects. To prevent warping, users should minimize cooling and use an enclosure if possible. Mesh bed leveling and careful Z-height calibration further improve print quality and strong adhesion.

- Perform PID autotune for the hotend and bed at target temperatures.

- Calibrate extruder steps for accurate filament flow.

- Use mesh leveling for consistent nozzle height.

- Adjust print speed and layer height for the best balance of print quality and speed.

TPU and Flexible

The Sovol SV08 Max handles flexible 3d materials like TPU with ease. Users should set the nozzle temperature to 220°C-240°C and the bed temperature to 40°C-60°C. Print speeds between 20 and 40 mm/s help maintain print accuracy and prevent filament stretching. The Smart Auxiliary Feeder ensures smooth filament feeding, reducing the risk of jams. Minimal retraction settings (1-2 mm) and slow retraction speeds (20-30 mm/s) prevent clogging and improve print quality. The thick aluminum bed and advanced bed leveling technology provide strong adhesion, even for flexible prints.

Note: For all 3d printing projects, the Sovol SV08 Max’s high-flow nozzle and multi-fan cooling system deliver consistent print quality, accuracy, and precision across a wide range of materials. Users can rely on this printer for high performance and excellent results.

Large Build Volume

The Sovol SV08 Max stands out as a large format 3D printer with a 500×500×500 mm build volume. This expansive volume allows users to tackle ambitious projects that smaller printers cannot handle. The combination of high-speed printing, advanced accuracy, and a sturdy frame ensures reliable results for every large-scale print.

Custom Cosplay Armor

Cosplayers and prop makers benefit greatly from the Sovol SV08 Max’s 500×500×500 mm build volume. They can print large props and custom cosplay armor in one piece, which eliminates the need for complex assembly. The ability to produce full armor pieces in a single print run saves time and reduces weak points. Many users report that the 500×500×500 mm volume enables them to create custom cosplay armor with improved structural integrity and smoother finishes. The Sovol SV08 Max’s accuracy, with positional deviation as low as 0.02 mm, ensures that every detail in custom cosplay armor appears crisp and precise. The large build volume also allows for creative freedom, letting designers experiment with intricate designs and oversized accessories. The high-speed printing capability, up to 700 mm/s, means users can complete custom cosplay armor projects faster without sacrificing quality.

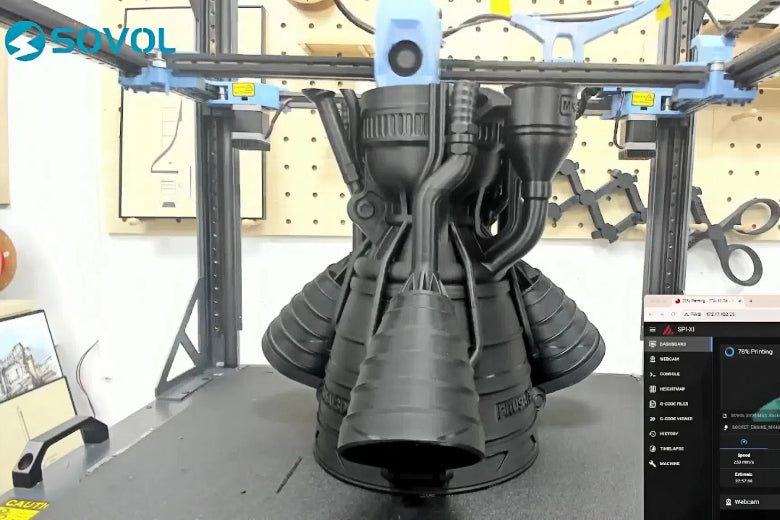

Industrial Parts

Engineers and manufacturers rely on the Sovol SV08 Max for industrial parts that demand both size and accuracy. The 500×500×500 mm build volume supports the production of large components, full-scale prototypes, and functional assemblies. The printer’s accuracy and 92% reduction in ringing artifacts deliver sharp edges and consistent dimensions. The robust frame and automatic bed leveling system minimize print failures, making the Sovol SV08 Max a dependable choice for industrial applications. Users appreciate the ability to print large props, jigs, and fixtures in one piece, which streamlines workflow and enhances part durability. The large format 3D printer’s material versatility further expands its use in various industries.

Oversized Models

Artists, architects, and designers use the Sovol SV08 Max to bring oversized models to life. The 500×500×500 mm build volume accommodates furniture parts, architectural models, and exhibition pieces. The large format 3D printer’s high-speed printing and accuracy ensure that even the most complex models maintain their intended form and detail. Users often highlight the ease of use and reliability when working with such a large volume. The Sovol SV08 Max’s advanced features, including a 50 mm³/s extrusion rate and multi-fan cooling, support consistent results across the entire 500×500×500 mm build area. This capability empowers creators to push boundaries and realize their visions on a grand scale

The Sovol SV08 Max’s combination of large build volume, accuracy, and speed makes it the preferred choice for professionals and hobbyists who demand more from their 3D printer.

|

Feature |

Sovol SV08 Max |

Competitors (e.g., Bambu Lab) |

|---|---|---|

|

Build Volume |

500×500×500 mm |

Smaller volumes |

|

Maximum Print Speed |

Up to 700 mm/s |

Up to 500 mm/s |

|

Positional Deviation |

≤0.02 mm |

N/A |

|

Ringing Artifact Reduction |

92% reduction |

N/A |

|

Material Extrusion Rate |

50 mm³/s |

N/A |

Troubleshooting & Tips

Print Quality

Achieving high print quality on the Sovol SV08 Max requires attention to detail and regular maintenance. Users should clean the nozzle and heated bed after each print to prevent clogs and ensure strong adhesion. Lubricating moving parts reduces friction and extends the printer’s lifespan. The Sovol SV08 Max’s CoreXY kinematics and Eddy Current Scanning bed leveling system help maintain precise motion and optimal first-layer adhesion, which leads to consistent results and fewer print failures. Monitoring the extruder for clogs and keeping the build plate free of debris also contribute to reliable print quality. Users who store filaments in dry conditions avoid moisture-related issues that can affect print quality and detailed results.

Tip: Use slicing software to optimize layer height and print speed for each filament type. Adjusting these settings improves print quality and produces detailed results.

Material Switching

Switching between different print materials, especially abrasive or flexible filaments, requires careful preparation. Users should always clean the nozzle thoroughly before changing materials to prevent contamination and clogging. When switching from abrasive filaments like PETG-CF to standard materials, replacing the nozzle ensures fewer print failures and maintains print quality. For flexible filaments, slow down the print speed and reduce retraction to avoid jams. The Sovol SV08 Max’s smart auxiliary feeder system monitors filament feeding, which helps prevent tangles and clogs during material changes.

Common Issues

Common print issues include warping, nozzle clogging, and poor bed adhesion. The Sovol SV08 Max addresses these challenges with advanced features. The thick 8mm aluminum hotbed provides rapid, even heating, minimizing warping and improving adhesion for large prints. Smart sensors and live feedback systems detect errors in real time, allowing users to pause and fix problems early. Regular maintenance, such as cleaning dust and debris, tightening bolts, and updating firmware, leads to fewer print failures and higher print quality. Using high-quality filament and calibrating print parameters also help avoid common problems.

- Clean the nozzle and bed after every print.

- Lubricate moving parts regularly.

- Store filament in dry, sealed containers.

- Use the Sovol SV08 Max’s real-time monitoring tools for early error detection.

These steps ensure reliable print quality and maximize the Sovol SV08 Max’s performance for every print job.

Selecting the right 3D print material unlocks the Sovol SV08 Max’s full potential. Its large build volume of 500×500×500 mm supports oversized projects, while the CoreXY system and high-flow extrusion deliver speed and precision. The advanced bed leveling and smart feeder ensure consistent results across the entire volume. Users benefit from reliable adhesion and reduced print failures, even with complex materials. Professionals and hobbyists can explore new applications, experiment with advanced filaments, and maximize every cubic volume of their printer. For deeper insights, users should review material-specific guides and join expert forums.

FAQ

What materials work best for large-scale prints on the Sovol SV08 Max?

PLA and PETG perform exceptionally well for large prints. These materials offer strong adhesion and minimal warping. The Sovol SV08 Max’s heated bed and advanced leveling system further enhance results with these filaments.

How does the Smart Auxiliary Feeder help with flexible filaments?

The Smart Auxiliary Feeder ensures smooth filament feeding. It detects tangles and clogs quickly. This feature reduces print failures when using flexible materials like TPU, making the process more reliable for users.

Can the Sovol SV08 Max print with abrasive filaments like carbon fiber composites?

Yes, the Sovol SV08 Max supports abrasive filaments such as PETG-CF. Users should install a hardened steel nozzle for these materials. This upgrade prevents excessive wear and maintains consistent print quality.

What should users do if prints show poor bed adhesion?

Tip: Clean the bed thoroughly before each print. Adjust the Z-offset for optimal first-layer height. Use a suitable adhesive, such as a glue stick or PEI sheet, to improve adhesion. The printer’s heated bed also helps reduce warping and lifting.

Is it necessary to recalibrate the printer when switching materials?

Users should recalibrate the bed and check nozzle temperature settings after changing materials. This practice ensures optimal print quality and prevents issues related to temperature differences or material residue.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.