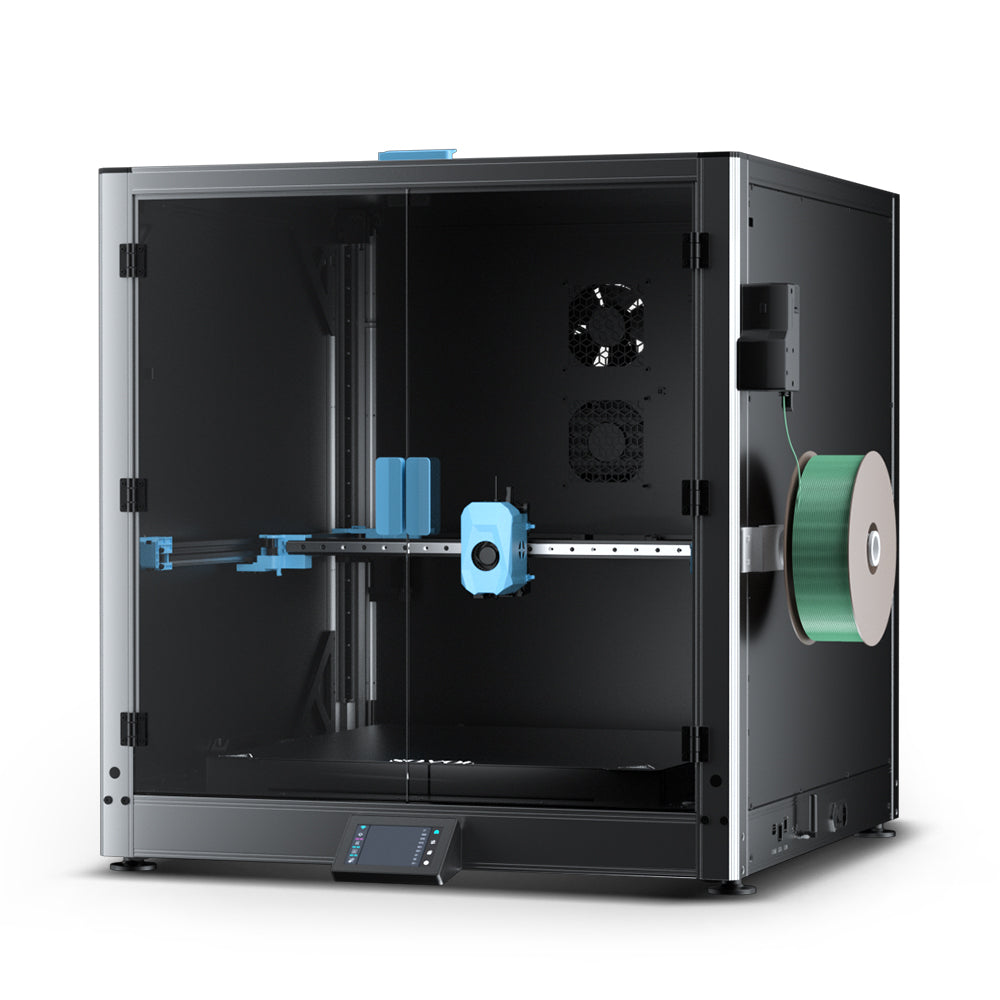

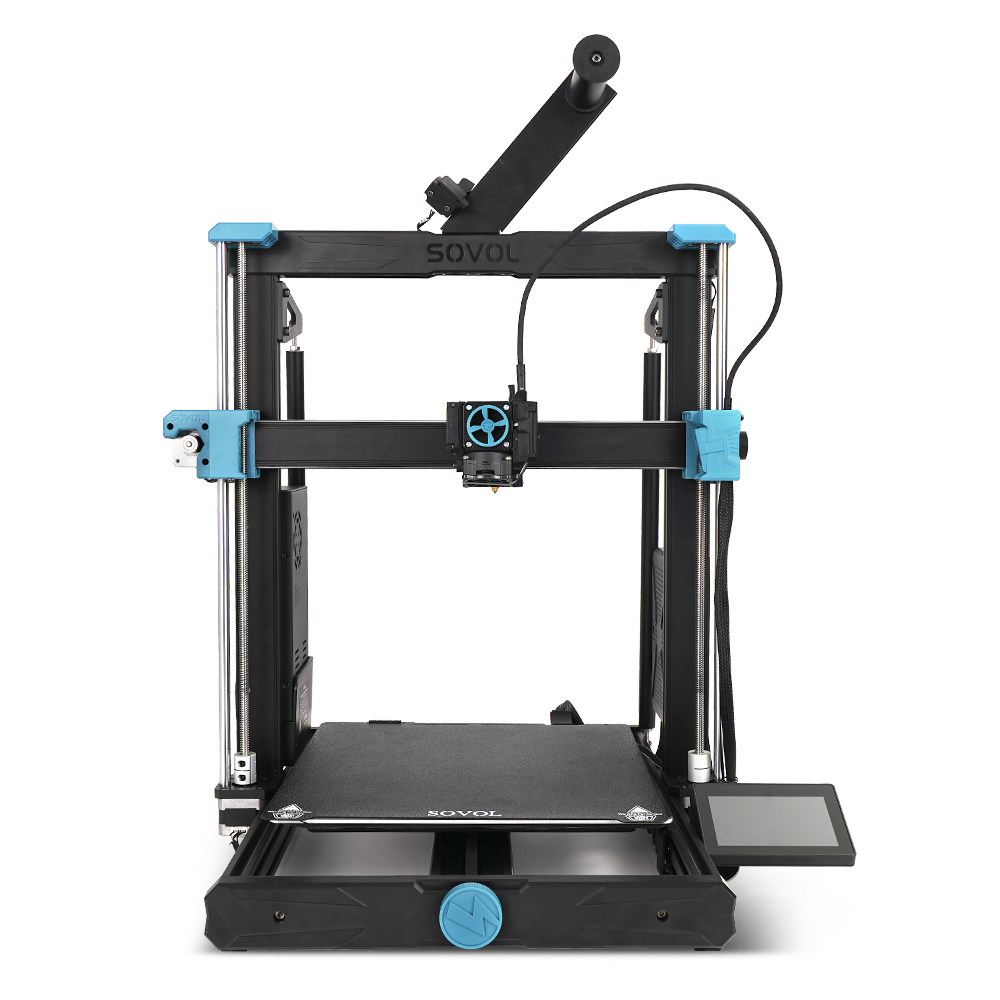

You can stop 3d printer stringing fast by changing a few settings. Many people have this annoying problem. Sovol’s open-source technology and easy design help you fix it fast. The SV06 PLUS is simple for beginners and intermediate users. It helps you get clean prints. Try these expert tips today and see quick results.

Key Takeaways

Change retraction to 1.5 mm and 35 mm/s for cleaner prints. Set nozzle heat to 200-210°C for PLA and 230-240°C for PETG to stop oozing. Always use dry and good filament to avoid stringing from moisture. Make travel speed 150 mm/s and turn on Z lift in your slicer for better prints. Join the Sovol group for help and tips to make your 3D printing better.

3D Printer Stringing Causes

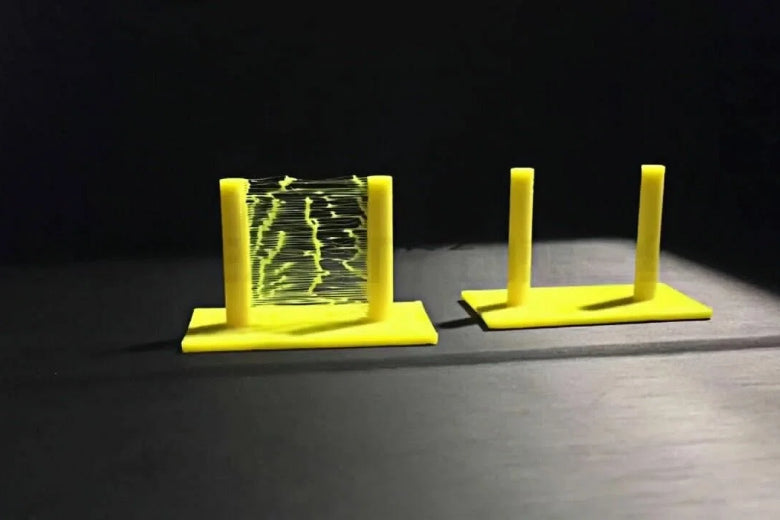

When you see thin, messy threads on your print, that is stringing. Knowing why stringing happens helps you fix it fast. Here are the main reasons and how Sovol’s open-source design and SV06 PLUS can help.

Retraction Settings

Retraction pulls filament back before the print head moves. Wrong retraction settings cause lots of stringing.

Bad retraction settings are the main reason for stringing in FDM 3D printing. If the retraction distance is too short or the speed is too slow, the filament does not pull back enough. This makes it drip during travel moves.

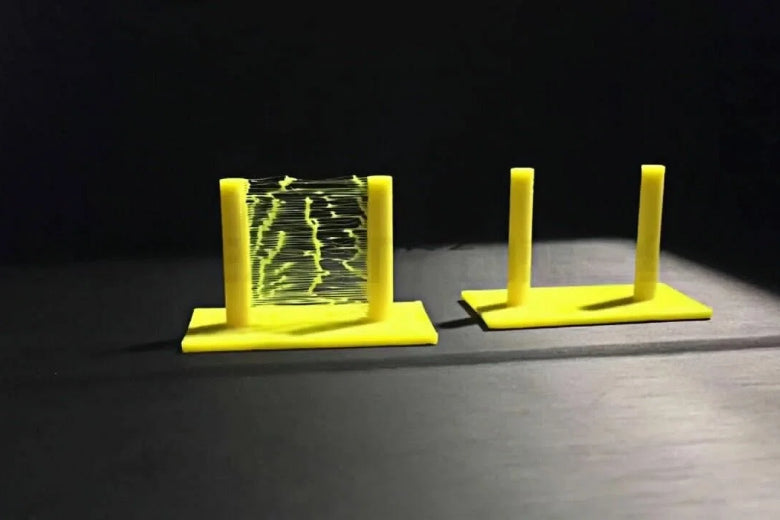

The Sovol SV06 PLUS has a direct drive extruder. This gives you better control over retraction. Set the retraction distance to 4-6mm and speed to 40-50mm/s for PLA. This helps stop stringing and keeps your prints neat.

Printing Temperature

If the nozzle is too hot, the filament melts too much. This is called excessive nozzle temperature. The melted filament drips out and causes stringing. For Sovol printers, use 200-210°C for PLA and 230-240°C for PETG. The SV06 PLUS all-metal hotend works well at these temperatures.

Filament Quality and Moisture

Wet or cheap filament can cause stringing. Moisture in the filament turns to steam in the hotend. This makes bubbles and oozing. Always use dry, good-quality filament. Sovol’s filament dryers help keep your filament dry.

Movement Speed and Z Lift

If the printer moves slowly, the nozzle has more time to ooze. Increase travel speed to 150mm/s on the SV06 PLUS for better prints. Turn on Z lift in your slicer. This lifts the nozzle a little during travel moves and helps stop stringing.

When you know these causes, you can fix stringing on your Sovol printer.

Eliminate Stringing Fast

You can stop stringing fast by using these steps. Each step fixes a different cause. The Sovol SV06 PLUS makes changes easy with its smart features.

Adjust Retraction (SOVOL SV06 PLUS Direct Drive)

Retraction is the key setting to stop stringing or oozing. Turn on retraction in your slicer and set it up right. The SV06 PLUS has a direct drive extruder. This gives you more control over retraction. Direct drive needs less retraction distance than Bowden.

Here is a table with the best retraction settings for Sovol SV06 PLUS:

|

Setting |

Recommended Value |

|---|---|

|

Enable retraction |

Yes |

|

Retraction distance |

1–2 mm (direct drive) |

|

Retraction speed |

25–45 mm/s |

Use these numbers for PLA and PETG. Try 1.5 mm distance and 35 mm/s speed first. If you still see stringing, make the speed a bit higher. Always test with a small print before a big one.

Tip: The SV06 PLUS direct drive extruder changes retraction fast. You can adjust settings for each filament and see results quickly.

Optimize Temperature (SOVOL Hotend Ranges)

Nozzle temperature changes how much filament oozes. If it is too hot, you get more stringing. The SV06 PLUS all-metal hotend works with many materials.

For PLA, set the nozzle to 200°C to 210°C. For PETG, use 230°C to 240°C. Lower heat means less oozing, but too low can cause under-extrusion. Always check the filament maker’s guide.

Note: The SV06 PLUS hotend heats up fast and stays steady. This helps you stop stringing and get smooth prints.

Use Dry Filament (SOVOL Filament Dryer)

Wet filament causes oozing and stringing. Water in the filament turns to steam in the hotend. This makes bubbles and drips. Always use dry filament for the best prints.

Sovol filament dryers like SH01 and SH02 keep filament dry. Put your spool in the dryer for a few hours before printing. For PLA, dry at 45°C for 4–6 hours. For PETG, dry at 55°C for 6 hours.

- Dry filament prints better and stops stringing.

- Sovol dryers work with all normal filament sizes.

Tip: After drying, store filament in a sealed bag with desiccant. This keeps it dry until you print again.

Enable Wipe, Coasting, and Z Lift

You can use slicer tools to stop stringing fast. Wipe and coasting help control oozing at the end of each move. Z lift raises the nozzle during travel moves to stop dragging and stringing.

- Wipe: The nozzle goes back over the last part to clean off extra filament.

- Coasting: The extruder stops pushing filament just before the end. It uses leftover pressure to finish the line.

- Z Lift: The nozzle lifts up 0.2–0.5 mm during travel. This keeps it away from the print and stops oozing.

Turn on these features in your slicer. The SV06 PLUS works with all main slicers, so you can change these settings easily.

Tip: Start with a Z lift of 0.2 mm and test your print. Make it higher if you still see stringing.

You can stop stringing by following these steps. Change retraction, set the right temperature, use dry filament, and turn on wipe, coasting, and Z lift. The Sovol SV06 PLUS and Sovol filament dryers make these steps easy. You will get cleaner prints and less oozing right away.

Sovol Tips for Stringing Prevention

You want to stop 3d printer stringing and get clean prints every time. Sovol offers many common solutions and helpful resources. You can use these techniques and methods to prevent stringing on your SV06 PLUS and other Sovol printers.

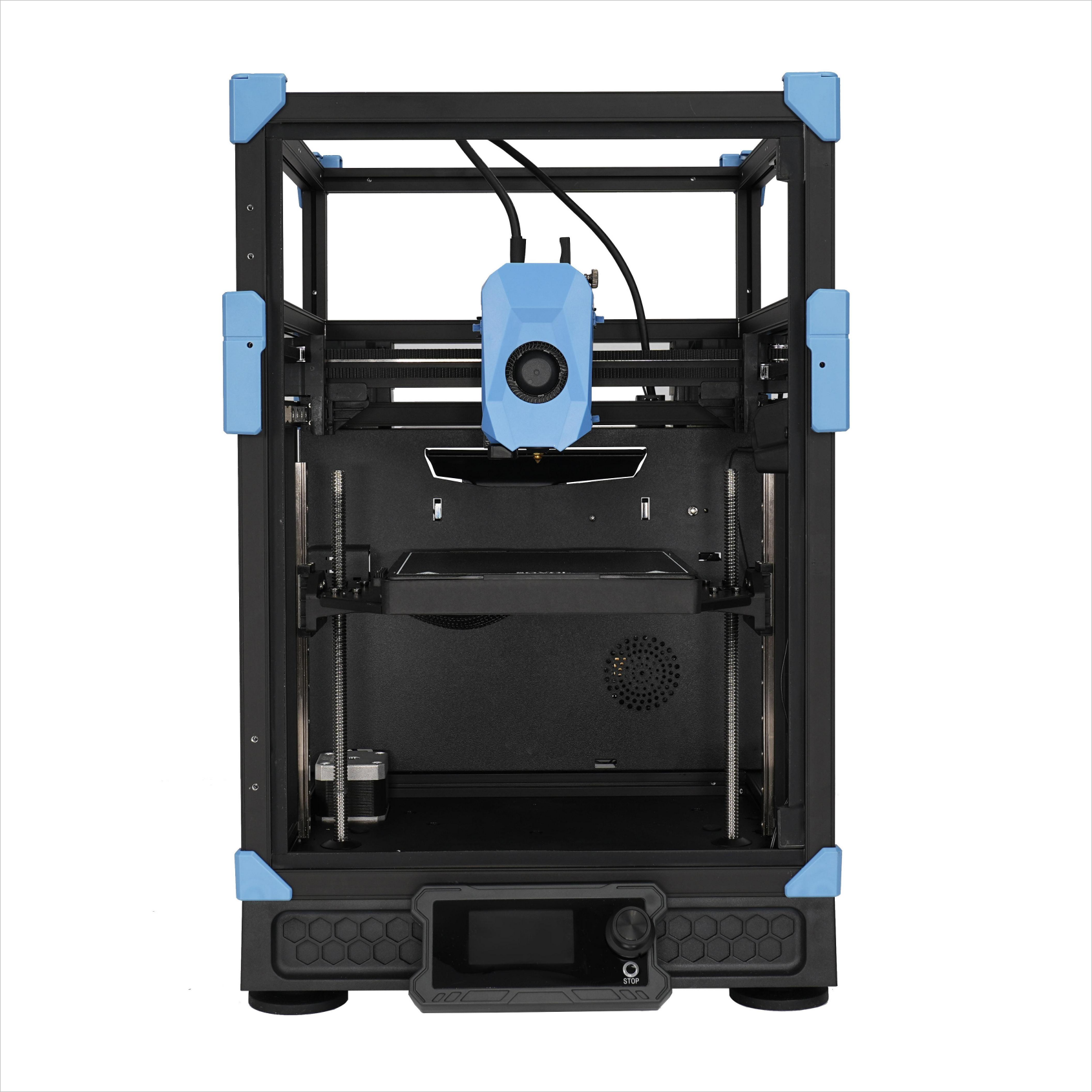

SV06 PLUS Recommended Settings

The SV06 PLUS gives you control over your print settings. You can adjust retraction, temperature, and travel speed to reduce stringing.

- Set retraction distance to 1.5 mm for PLA and PETG.

- Use retraction speed of 35 mm/s.

- Set nozzle temperature to 200°C for PLA and 235°C for PETG.

- Increase travel speed to 150 mm/s.

- Enable Z lift at 0.2 mm.

You can use the table below to check the best settings for your Sovol SV06 PLUS:

|

Setting |

PLA Value |

PETG Value |

|---|---|---|

|

Retraction Distance |

1.5 mm |

1.5 mm |

|

Retraction Speed |

35 mm/s |

35 mm/s |

|

Nozzle Temperature |

200°C |

235°C |

|

Travel Speed |

150 mm/s |

150 mm/s |

|

Z Lift |

0.2 mm |

0.2 mm |

Tip: You can test these settings with a small print first. If you see stringing, adjust the retraction speed or temperature.

Slicer and Firmware Adjustments

You can use slicer profiles and firmware features to prevent stringing. Sovol printers work with many slicers, including Cura and PrusaSlicer.

- Turn on "avoid crossing outline for travel movement" in your slicer. This keeps the nozzle away from open spaces and reduces stringing.

- Enable wipe and coasting features. These help clean the nozzle and stop oozing.

- Update your firmware to the latest version. Sovol releases updates that improve print quality and add new features.

- Use Sovol’s recommended slicer profiles from the Sovol Wiki. These profiles have tested settings for different filaments.

Note: You can find slicer profiles and firmware guides on the Sovol Wiki. The Wiki has step-by-step instructions for your printer.

Maintenance and Sovol Community Support

Regular maintenance helps you prevent stringing and keep your printer working well. Sovol supports you with guides and a strong community.

- Clean your nozzle and extruder often. This stops clogs and keeps extrusion smooth.

- Store filament in a dry box or use a Sovol filament dryer.

- Check belts and screws for tightness.

- Join the Sovol community for help and advice. You can ask questions and share your results.

- Visit the Sovol Wiki for troubleshooting guides and tips.

Tip: If you have trouble with stringing, you can post your problem in the Sovol user group or check the Sovol Wiki for solutions.

You can use these Sovol tips and techniques to prevent stringing. Adjust your SV06 PLUS settings, use slicer and firmware features, and keep your printer in good shape. Sovol’s community and resources help you solve problems and improve your prints.

Troubleshooting 3D Printer Stringing

Step-by-Step Diagnosis

You can solve most stringing problems by following a simple checklist. Start with these steps:

-

Check Filament Condition

Make sure your filament is dry. Use a Sovol filament dryer if you see bubbles or hear popping sounds during printing. -

Inspect Retraction Settings

Open your slicer and look at the retraction distance and speed. For Sovol SV06 PLUS, set retraction distance to 1.5 mm and speed to 35 mm/s. -

Review Nozzle Temperature

Look at your temperature settings. For PLA, use 200°C. For PETG, use 235°C. High temperatures cause more oozing. -

Test Travel Speed and Z Lift

Set travel speed to 150 mm/s. Enable Z lift at 0.2 mm. Fast moves and Z lift help reduce stringing. -

Examine Slicer Features

Turn on wipe and coasting. These features clean the nozzle and stop extra filament from leaking.

Tip: Print a small test object after each change. You will see which adjustment works best.

Quick Fixes and When to Seek Help

If you still see 3d printer stringing after checking the basics, try these quick fixes:

- Lower nozzle temperature by 5°C.

- Increase retraction speed by 5 mm/s.

- Dry your filament for a few more hours.

- Clean the nozzle with a soft brush.

If problems continue, you can get help from Sovol support channels:

|

Support Option |

How to Use |

|---|---|

|

Sovol Wiki |

Find guides and troubleshooting tips |

|

Sovol User Group |

Ask questions and share photos |

|

Sovol Official Support |

Contact for technical help |

Note: Many Sovol users share their solutions in the community. You can read real stories, like the SV08 hands-on review, to learn more.

You can fix stringing by following these steps and using Sovol resources. You will get cleaner prints and enjoy your 3D printing projects.

You can stop 3d printer stringing fast by changing a few things. Adjust retraction, set the right temperature, and keep filament dry. Try Sovol SV06 PLUS settings to get clean prints. Sovol filament dryers and slicer tools help stop stringing.

- Join the Sovol community to get help and learn new tips.

- Check out Sovol SV07 and other products on the Sovol website for more ways to fix problems.

Sovol gives you tools and advice to help you create. You can trust their support and get better at 3d printing.

FAQ

What causes stringing on my Sovol 3D printer?

Stringing happens when melted filament leaks during travel moves. You may see thin threads on your print. Common causes include high nozzle temperature, wet filament, slow travel speed, or incorrect retraction settings.

How do I fix stringing quickly?

You can adjust retraction distance and speed, lower nozzle temperature, dry your filament, and enable Z lift in your slicer. Try Sovol’s recommended settings for fast results.

What is the best retraction setting for SV06 PLUS?

Set retraction distance to 1.5 mm and speed to 35 mm/s for PLA and PETG. You can test these values with a small print and adjust if needed.

Should I use a filament dryer?

Yes. Dry filament prints cleaner and reduces stringing. Sovol filament dryers like SH01 and SH02 help keep your filament dry and ready for use.

Where can I find more Sovol troubleshooting tips?

Visit the Sovol Wiki for guides, slicer profiles, and firmware updates. You can also join the Sovol user group to ask questions and share your results.