PLA filament stands out as the most popular choice for 3D printing filament. You get strong prints, smooth surfaces, and reliable quality every time. Many users load the PLA filament because it is easy to use and a popular choice for beginners. PLA offers a low-cost option and does not emit strong fumes. You can trust this filament for both home and school projects. PLA comes from renewable sources, making it eco-friendly. With minimal warping and wide availability, you can enjoy 3D projects without hassle.

Most users report that PLA is simple to print, affordable, and does not cause unpleasant odors, which makes it perfect for your 3D creations.

Key Takeaways

- PLA filament is easy to use and beginner-friendly, requiring low printing temperatures and minimal special equipment, which makes 3D printing simple and hassle-free.

- PLA produces high-quality prints with smooth surfaces and fine details, while being affordable and widely available in many colors and brands.

- PLA is eco-friendly because it comes from renewable resources and is biodegradable, making it a great choice for sustainable and safe 3D printing projects.

PLA Filament Advantages

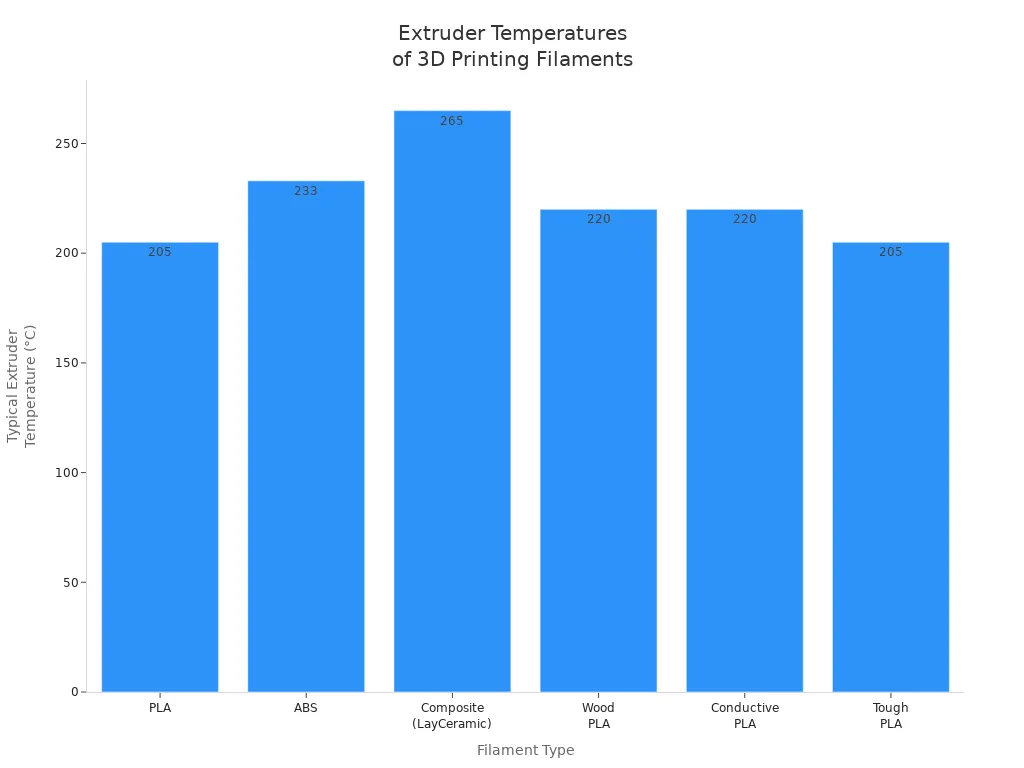

Ease of Use

You will find that PLA filament is one of the most easy to use materials for 3D printing. PLA prints at lower temperatures, usually between 200°C and 220°C. You do not need a heated bed, and you rarely see warping. This makes PLA a top choice for both beginners and experienced users. You can print with PLA on most desktop 3D printers without special equipment. Unlike ABS or PETG, PLA does not require an enclosure or strong ventilation. You avoid strong fumes and can print safely at home or in a classroom.

Here is a comparison of key features that make PLA filament stand out:

|

Feature |

PLA |

ABS |

PETG |

|---|---|---|---|

|

Printing Temperature |

Lower (200-220°C) |

Higher (220-250°C) |

Higher (230-245°C) |

|

Heated Bed Required |

No (or low temp ~50-60°C) |

Yes |

Yes (~80-90°C) |

|

Warping Tendency |

Minimal due to low thermal expansion |

High, prone to warping |

Moderate, requires heated bed |

|

Enclosure Needed |

No |

Yes |

No |

|

Post-processing Ease |

Easier due to lower melting point |

Moderate |

More difficult due to heat resistance |

|

Fume Emission |

Minimal |

Emits fumes, needs ventilation |

Emits fumes, needs ventilation |

|

Beginner Friendliness |

High |

Lower due to complexity |

Moderate |

You can see that PLA filament offers a smooth experience from start to finish. You spend less time troubleshooting and more time creating. PLA is also less sensitive to temperature changes and moisture than other 3d printing filament types. If you want a reliable and easy to use option, PLA is the best place to start.

Tip: If you notice stringing or poor bed adhesion with PLA, try adjusting your nozzle and bed temperatures in small steps. Most users solve these issues quickly, making PLA even more user-friendly.

Print Quality

When you print with PLA filament, you get high-quality prints with sharp edges and fine details. PLA’s properties help you achieve smooth surfaces and excellent dimensional accuracy. You can create intricate designs and prototypes that look professional. PLA has a low shrinkage rate, so your 3d models keep their shape and size. This makes PLA ideal for projects that require tight tolerances.

Here is a comparison of print quality features:

|

Filament |

Surface Finish |

Dimensional Accuracy |

Additional Notes |

|---|---|---|---|

|

PLA |

Sharp edges, fine details, minimal warping, ideal for high-resolution prints |

Low shrinkage, better accuracy, easy to achieve tight tolerances |

Prints at lower temperatures, easiest to print |

|

ABS |

Surface can warp, needs heated bed and enclosure, can be smoothed with acetone |

Higher shrinkage, more prone to warping, needs more calibration |

Prints at higher temperatures, more challenging |

|

PETG |

Good finish, strong adhesion, can string, needs tuning |

Good accuracy, low warping |

Prints at higher temperatures, balances strength and quality |

You will notice that PLA filament produces high-quality filaments with consistent results. Most users report fewer defects, such as warping or odor, compared to ABS. PLA does sometimes show stringing or adhesion issues, but you can fix these with simple adjustments. PLA’s properties make it a favorite for both hobbyists and professionals who want high-quality prints every time.

Affordability

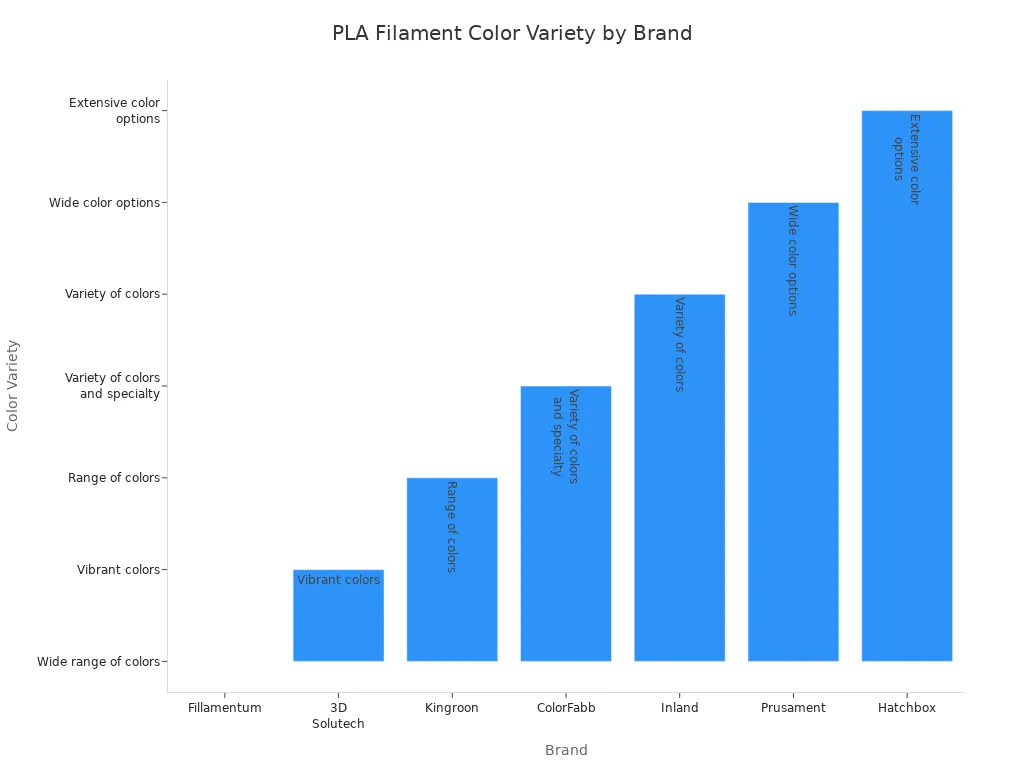

PLA filament is a cost-effective choice for 3d printing. You can find PLA in almost every 3d printing store, both online and offline. PLA is one of the most widely used materials because it is affordable and available in many colors and brands. You can choose from a huge range of shades, including unique and vibrant options.

You can see that brands like Hatchbox, Prusament, and Fillamentum offer a wide selection of PLA colors. This variety lets you match your project’s needs and express your creativity.

When you compare prices, PLA filament is generally less expensive than other 3d printing filament types. Here is a quick look at average prices:

|

Filament Type |

Average Price per kg (USD) |

|---|---|

|

ABS |

$10 |

|

PLA |

$15 |

|

PETG |

$15 |

While ABS may sometimes cost less, PLA offers better ease of use, quality, and color variety for the price. You get strong, high-quality prints without spending a lot. PLA’s cost-effective nature makes it perfect for schools, makerspaces, and anyone who wants to print more for less.

Note: PLA filament also uses less energy during printing because it does not need a heated bed or high extrusion temperatures. This helps you save on electricity and makes PLA an even more affordable and eco-friendly option.

Properties of PLA

Strength and Structure

You can rely on the properties of PLA to deliver strong and reliable 3D prints. PLA filament has low thermal expansion, which means your prints will not warp or shrink much as they cool. This property helps you create models with precise dimensions and sharp details. PLA’s low melting temperature, usually around 205°C, makes it easy to print and reduces the risk of overheating or damaging your printer.

When you look at the strength of PLA filament, you will notice that it performs well for most everyday uses. PLA is hard and maintains its shape, but it can be brittle under heavy impact. The structural integrity of your 3D prints depends on several factors, such as printing temperature, layer height, and infill pattern. For example, printing at around 220°C improves interlayer bonding and makes your models stronger. Smaller layer heights, like 0.1 mm, increase load capacity and reduce defects. Lower print speeds also help by allowing better fusion between layers.

Here is a table that shows how different printing parameters affect the structural properties of PLA:

|

Parameter |

Effect on PLA 3D Prints |

|---|---|

|

Printing Temperature |

Optimal at ~220°C for best strength; above 240°C causes brittleness |

|

Layer Height |

0.1 mm improves load capacity and reduces defects |

|

Print Speed |

40 mm/s enhances strength and rigidity |

|

Infill Density |

Lower infill reduces bonding strength; skin layers dominate in small prints |

|

Printing Orientation |

X/Y axis gives higher strength; Z axis can be brittle |

|

Filament Width |

Larger width increases stiffness and bending resistance |

You can also compare the impact resistance and tensile strength of different filaments:

|

Filament Type |

Tensile Strength (PSI) |

Impact Resistance (kJ/m²) XY Plane |

Impact Resistance (kJ/m²) Z Plane |

Notes |

|---|---|---|---|---|

|

PLA (standard) |

N/A |

~7 |

~7 |

Nearly isotropic, good adhesion |

|

ABS |

16-23 |

1.5-3.3 |

Strong in XY, weak in Z |

|

|

PETG |

N/A |

7-14 |

2-7 |

Variable, sometimes better in XY |

|

PLA+ |

N/A |

2-4x standard PLA (up to ~14-28) |

Slightly better than standard PLA |

Improved impact resistance |

PLA filament properties make it a great choice for models, prototypes, and low-stress parts. If you need more durability, you can use tough PLA or adjust your print settings for better results. The composition of PLA gives you a balance of strength and printability, making it ideal for most 3D projects.

Tip: For the strongest PLA prints, use a higher infill, lower layer height, and print at the optimal temperature. This will help your models withstand more stress and last longer.

Eco-Friendly Material

PLA stands out as an environmentally friendly material. The composition of PLA comes from renewable resources like corn starch and sugarcane. Manufacturers ferment these crops to produce lactic acid, which forms the base of PLA filament. Some brands even use recycled material, with up to 87% of their PLA coming from post-industrial waste.

PLA is biodegradable, which means it breaks down into natural compounds under the right conditions. In industrial composting facilities, PLA decomposes within 90 to 180 days when exposed to heat, moisture, and microbes. Traditional plastics, on the other hand, can take hundreds of years to break down and often pollute the environment with microplastics.

|

Parameter |

PLA Biodegradation (Industrial Composting) |

Traditional Plastics Biodegradation |

|---|---|---|

|

Temperature |

55-60°C (131-140°F) |

Not biodegradable |

|

Moisture Content |

50-60% |

Not biodegradable |

|

Microbial Activity |

Required |

Ineffective |

|

Timeframe |

90-180 days |

Hundreds of years |

You help the environment by choosing PLA filament. Its production uses less energy and creates fewer carbon emissions than petroleum-based plastics. The plants used to make PLA absorb CO2 as they grow, which helps offset emissions from manufacturing. PLA also requires lower extrusion temperatures during 3D printing, saving even more energy.

- PLA is biodegradable and compostable, reducing plastic waste.

- PLA comes from renewable crops, not fossil fuels.

- PLA filament production has a smaller carbon footprint.

- Composting PLA prevents microplastic pollution.

Note: PLA is safe for home and educational use. It does not emit strong fumes, making it a good choice for classrooms and indoor spaces.

Versatility in 3D Printing

You will find that the versatility of PLA filament sets it apart from other materials. PLA supports a wide range of print features, including complex curves, fine details, and intricate internal structures. You can print prototypes, models, and even functional parts with PLA. Its low warping and easy printability allow you to create complex designs without special equipment.

|

Filament Type |

Print Features & Complexity |

Comparison to Other Filaments |

|---|---|---|

|

PLA (Standard) |

Prototypes, low-stress parts, fine details |

Easier than ABS, more versatile |

|

Tough PLA |

Larger prints, complex curves, harsh overhangs |

More reliable than ABS for big projects |

|

Carbon Fiber Reinforced PLA |

Strong, wear-resistant parts, tools, frames |

Combines PLA ease with extra rigidity |

|

ABS |

Functional parts, but more warping and harder to print |

Less versatile due to print challenges |

|

PVA (Support Material) |

Enables complex geometries with PLA in dual extrusion printing |

Best support for intricate PLA designs |

PLA’s properties make it suitable for many applications. In prototyping, you can quickly test ideas and create models. In biomedical fields, PLA is used for medical devices, tissue engineering, and drug delivery systems because it is biocompatible and biodegradable. PLA is also popular in food packaging, as it is made from plant-based sources and considered safer for food contact.

Callout: PLA filament is a top choice for 3D printing in schools, makerspaces, and research labs. Its safety, ease of use, and wide range of applications make it perfect for learning and innovation.

The properties of PLA, including its renewable composition, low melting temperature, and ability to print complex features, make it a favorite among 3D printing enthusiasts. When you choose PLA filament, you support a more sustainable environment and enjoy reliable, high-quality prints for a variety of uses.

PLA Limitations

Drawbacks

You should know that PLA filament has some important limitations. PLA softens at low temperatures, with a glass transition point around 60°C. This means your prints can lose shape if left in a hot car or near a heat source. PLA also breaks more easily than other filaments like ABS or PETG. It is brittle and does not handle impact or bending well.

- PLA softens above 60°C, so it cannot withstand high heat.

- Sunlight and moisture cause PLA to degrade quickly outdoors.

- PLA is brittle, especially along the Z-axis, and has weaker tensile strength.

- It performs poorly in durability tests compared to PETG or ABS.

|

Property |

Value Range / Approximate |

|---|---|

|

53 °C |

|

|

Heat Deflection Temp |

80 °C |

|

Tensile Strength |

38 - 47.8 MPa |

|

Flexural Strength |

~85 MPa |

|

Hardness |

Shore D 66 |

You should avoid using PLA for parts that need to handle stress, heat, or outdoor conditions. PLA works best for cosmetic models, prototypes, or short-term projects.

Note: Many new users think PLA is perfect for every project, but it is not suitable for functional or outdoor parts that need toughness or flexibility.

Why PLA Remains Popular

Despite these drawbacks, you will see that PLA remains the top choice for many users. PLA is easy to print, affordable, and widely available. You can find it in many colors and specialty blends, such as wood, metal, or glow-in-the-dark. PLA comes from renewable resources, making it attractive if you care about the environment.

- PLA prints at low temperatures and rarely warps, so you get reliable results.

- You do not need special equipment or ventilation.

- PLA’s eco-friendly nature appeals to schools, hobbyists, and professionals.

- New blends, like carbon fiber PLA, improve strength and expand uses.

- A strong community and ongoing innovation keep PLA at the center of 3D printing.

Tip: If you need more strength or heat resistance, try reinforced PLA blends or adjust your print settings. Many professionals use these strategies to get the best results from PLA.

You can rely on PLA for most creative, educational, and prototyping needs. Its balance of ease, cost, and versatility explains why so many people pick PLA filament for their 3D printing projects.

You can rely on PLA filament for easy printing, consistent quality, and eco-friendly results. Its low printing temperature, affordability, and versatility make it a top choice for 3D projects.

|

Benefit |

Description |

|---|---|

|

Simple to use, minimal warping |

|

|

Eco-friendly |

Biodegradable, plant-based |

|

Cost-effective, widely available |

|

|

Suits many applications |

FAQ

What is the best way to store PLA filament?

Keep PLA filament in a cool, dry place. Use a sealed bag with desiccant packs. This prevents moisture from causing brittle prints or poor extrusion.

Tip: Store unused spools in airtight containers for best results.

Can you paint or finish PLA prints?

Yes, you can sand, prime, and paint PLA prints. Use acrylic paints for best results. Always clean and dry your print before painting.

Is PLA filament food safe?

Some PLA filaments are labeled food safe, but you should check with the manufacturer. Printing conditions and additives may affect safety. Avoid using printed items for long-term food contact.