You want parts that are strong and last a long time. This is important for high-temperature 3D printing. The best heat-resistant 3D printing materials can handle high heat. They work well in places with a lot of heat. Some high-temperature resistant materials are ABS, ULTEM, PP, metal filaments, polycarbonate, PEEK, aluminum alloys, stainless steel, Inconel, and carbon fiber. These heat-resistant 3D printing filaments help you make working and industrial parts. These parts will last a long time. Picking the right heat-resistant materials keeps your 3D printing safe. It also makes your parts strong and helps you succeed. You can choose easy or advanced high-temp 3D printer filament types. The right heat-resistant filament and 3D printing materials make your parts work better. They also help them last longer in hot places.

Key Takeaways

- Pick heat-resistant materials like ABS, ASA, and PET-G. These are good for strong parts in hot 3D printing.

- Learn about how materials act. This helps you pick the best filament for your project.

- Keep your filament dry. Wet filament can cause bubbles and weak spots.

- Use a printer with a hotend that gets very hot. This is needed for advanced materials like PEEK and Ultem.

- Try easier materials like PET-G first. This helps you learn before using harder filaments.

High-Temperature 3D Printing Filaments: ABS, ASA, PET-G

Heat Resistance

You should pick heat-resistant 3D printing filament for hot jobs. ABS, ASA, and PET-G are popular choices for high heat. Many people use these materials for their projects. Look at the table below to see how much heat each can take:

|

Filament |

Maximum Operating Temperature |

|---|---|

|

ABS |

97ºC |

|

ASA |

98ºC |

|

PET-G |

70ºC |

ABS and ASA can handle more heat than PET-G. ASA is better than ABS for sunlight and weather. PET-G is easier to print and works well for many uses.

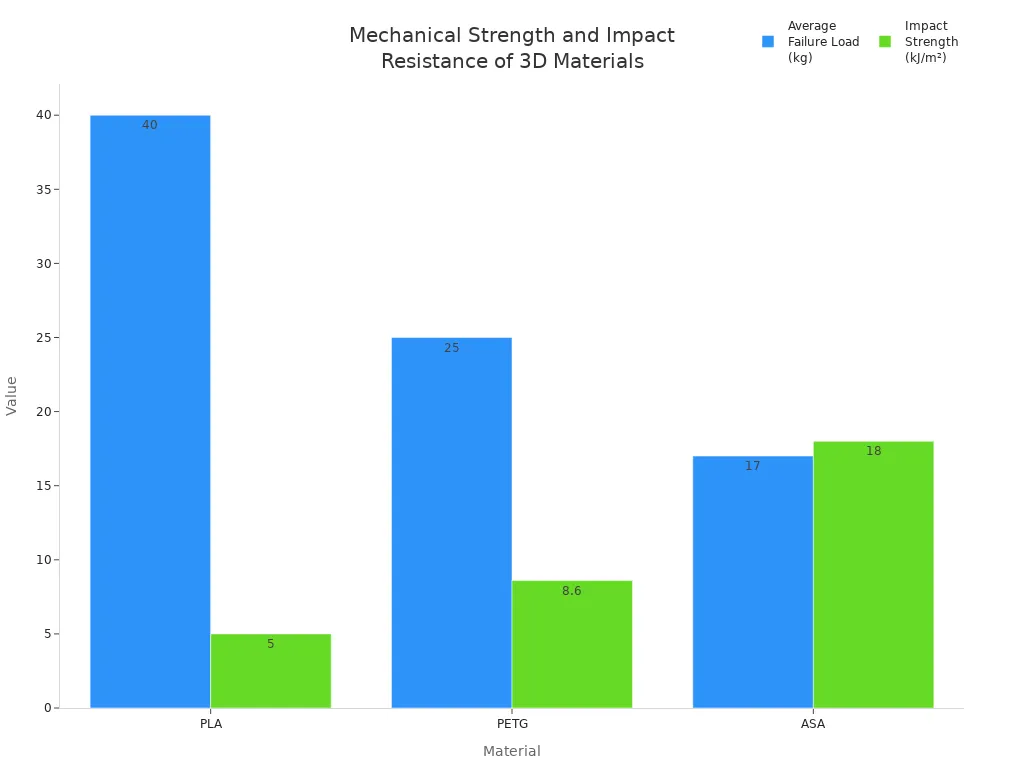

Mechanical Properties

You need strong parts for high-temperature 3D printing. ABS, ASA, and PET-G have different strengths. The table below shows how much force and impact each can take:

|

Material |

Average Failure Load (kg) |

Impact Strength (kJ/m²) |

|---|---|---|

|

PLA |

40 |

5 |

|

PETG |

25 |

8.6 |

|

ASA |

17 |

18 |

- PET-G can take more hits than PLA, so it is tougher.

- ASA can take the most hits, so it is the toughest of these heat-resistant 3D printing filaments.

Pros & Cons

ABS

- Pros: Handles heat well, strong, not expensive.

- Cons: Can bend out of shape, needs a hot bed, makes fumes.

ASA

- Pros: Great for weather, lasts long, does not fade in sun.

- Cons: Can bend, needs a cover, costs more than ABS.

- Pros: Easy to print, strong against hits, bends less.

- Cons: Handles less heat, can make strings, does not like water.

Applications

You can use these heat-resistant 3D printing materials for many things. The table below shows what each is good for:

|

Application Type |

|

|---|---|

|

Aesthetic and Concept Models |

PLA, PETG, ASA |

|

Functional Prototyping |

ABS, PETG, ASA |

|

End-Use Custom Parts |

PETG, ASA, ABS |

|

Outdoor and Weather-Exposed Applications |

ASA, PETG |

|

Educational and Learning Projects |

PLA, PETG |

|

Functional Assemblies and Moving Mechanisms |

ABS, PETG, ASA |

ASA is best for outdoor parts. ABS and PET-G are good for working models and moving parts.

Printing Requirements

You need the right printer settings for high-temp 3D printer filament. Use the table below to help you:

|

Filament |

Nozzle Temperature (°C) |

Bed Temperature (°C) |

|---|---|---|

|

ABS |

240 - 280 |

Recommended |

|

ASA |

240 - 280 |

Recommended |

|

PET-G |

240 - 270 |

Available |

- Use a hot bed for ABS and ASA to stop bending.

- PET-G works on most printers but needs to be dry.

- Keep all high temperature 3D printing materials dry. PET-G takes in water fast, so dry it before you print.

Tip: If you are new to high-temperature 3D printing, try PET-G first. It is easy to use and still strong.

Advanced Heat-Resistant 3D Printing Materials: PC, PA12, Nylon Composites

Heat Resistance

You can use advanced heat-resistant 3D printing materials for hot parts. Polycarbonate (PC), PA12, and Nylon composites work well in high heat. These materials handle more heat than basic filaments. Here are some key facts: PC can take heat up to 135°C. PA12 CF5 Carbon Fiber Composite also works up to 135°C. High-Strength PA12-CF5 Carbon Fiber Composite works at about 85°C. You need a nozzle that gets as hot as 350°C for these filaments. This makes them good for tough jobs.

Mechanical Properties

These 3D printing materials are strong and flexible. PA12 has a tensile strength of 48 MPa. It can stretch up to 20% before breaking. Nylon composites are even more durable and resist impacts. Your parts last longer and do not break easily.

Pros & Cons

PC, PA12, and Nylon composites are good for detailed parts. They resist chemicals and keep their shape well. These materials do not soak up much water, so they stay strong. Some Nylon composites can change color in sunlight. Warping can happen if you use the wrong printer settings. Moisture can cause problems, so dry your filament before printing.

Applications

You can use these heat-resistant 3D printing filaments in many industries. Here is a table with common uses:

|

Industry |

Applications |

|---|---|

|

Aerospace |

Flight-grade brackets, ducting, drone components |

|

Automotive |

Fuel lines, under-hood mounts, custom gaskets |

|

Industrial |

Jigs, fixtures, conveyor belts, wear-resistant gears |

|

Healthcare |

Prosthetic sockets, surgical guides, biocompatible implants |

|

Consumer Goods |

Durable phone cases, snap-fit enclosures, high-stress toys |

These materials are great for strong and tough parts.

Printing Requirements

You need a special printer for these high-temperature 3D printing jobs. Make sure your extruder gets up to 350°C. Use a heated chamber to stop warping. Dry your filament before you print, because water can ruin your part. If you are new to high-temp 3D printer filament, start with small parts and check your settings often.

Tip: Keep your heat-resistant 3D printing material in a dry box. This helps it stay ready for your next project.

Most Heat Resistant 3D Printing Filament: PEEK, PEKK, Ultem (PEI), PPSU, PSU

Heat Resistance

You need very heat-resistant filament for tough jobs. PEEK, PEKK, Ultem (PEI), PPSU, and PSU are best for hot places. These materials can handle heat for a long time. They also work when the temperature changes quickly. Here is how much heat each can take:

- PEEK: Works up to 250°C for many hours.

- Ultem (PEI): Handles up to 210°C.

- PEKK: Stays strong up to 160°C.

- PPSU: Works well at 180°C.

You need a printer with a nozzle that gets very hot, up to 500°C. The printer chamber should be heated to 90°C for these filaments.

Mechanical Properties

These materials are strong and resist chemicals and heat. They keep their shape even when stressed. Here is a table to compare them:

|

Material |

Tensile Strength |

Heat Resistance |

Chemical Resistance |

Cost Comparison |

|---|---|---|---|---|

|

PEEK |

High |

>250°C |

Broad |

Very High |

|

PEKK |

High |

160°C |

Moderate |

High |

|

Ultem (PEI) |

Moderate |

170°C |

Good |

Lower |

|

PPSU |

Lower |

180°C |

Superior |

Moderate |

PEEK and PEKK are very tough and last long. Ultem is strong and easier to print.

Pros & Cons

- PEEK: Works best for hot and tough jobs. It does not wear out fast. You need to set your printer just right.

- Ultem (PEI): Easier to print than PEEK. It costs less and works up to 210°C.

- PEKK: Very strong but costs more than Ultem.

- PPSU: Great against chemicals but not as strong.

- Cost: PEEK costs the most. Ultem is cheaper.

Tip: Dry your filament before you print. These filaments soak up water, which can mess up your print.

Applications

You can use these materials for jobs that need high heat:

- Aerospace: Engine parts, brackets, and ducts.

- Automotive: Parts under the hood and fuel system pieces.

- Medical: Tools for surgery and devices that can be cleaned.

- Industrial: Gears, insulators, and chemical parts.

These filaments make parts that last and work well.

Printing Requirements

You need a special printer for these filaments. Make sure your printer can do this:

|

Specification |

Value |

|---|---|

|

Maximum Nozzle Temperature |

Up to 500°C |

|

Heated Chamber Temperature |

90°C |

|

Supported Materials |

PEEK, PEKK, PEI, PPSU, PSU |

Keep your filament dry in a closed box. Use a dryer if you can. Try small prints first to check your settings. If you are new, ask for help or use easier materials.

Material Preparation and Storage for Heat-Resistant 3D Printing Filaments

Drying and Humidity Control

You must keep your filament dry before printing. Wet filament can make bubbles and weak spots. It can also make the surface look bad. Some 3D printing materials, like nylon composites and peek, soak up water from the air. Drying your filament helps it stay strong and keeps its chemical resistance.

Here is a table with drying temperatures and times for popular filaments:

|

Filament Type |

Drying Temp (°C) |

Recommended Time |

|---|---|---|

|

PLA |

45−55 |

4-6 Hours |

|

ABS |

80 |

2-4 Hours |

|

PET-G |

65 |

4-6 Hours |

|

Nylon |

80 |

6-8 Hours |

|

Ultem |

120 |

4-6 Hours |

|

PEEK |

120 |

4-6 Hours |

You can use a filament dryer or a food dehydrator. You can also use your printer’s heated bed. Always look at the instructions from the manufacturer for your materials.

Tip: If you see steam or hear popping while printing, your filament is wet. Dry it again before you print next time.

Storage Best Practices

Keep your high temperature filaments in a cool, dry spot. Humidity can hurt your filament and make it work worse. Use airtight containers or vacuum bags to block water. Put silica gel packs inside to soak up extra moisture.

- Put filament spools in sealed bins or bags.

- Keep bins away from sunlight and heat.

- Use filament boxes with humidity indicators.

- Use older filament first by rotating your stock.

If you do these things, your 3D printing materials will be ready for your next project. Good storage helps you get strong and reliable prints every time.

Note: Getting your filament ready and storing it right is important for high-temperature 3D printing. You protect your materials and help your parts last longer.

Printer Hardware for High-Temperature 3D Printing

If you want to print with high heat, your printer needs stronger parts. These upgrades help you use advanced 3D printing materials like peek and ultem. You get better prints for hot jobs and more chemical resistance.

Nozzle and Hotend Requirements

You need a special nozzle and hotend for high temperature filament. Regular parts cannot take the heat from peek and ultem. Here are the main upgrades you should get:

- Use a full metal hotend. This kind does not melt or break.

- Pick a hotend that gets up to 350°C or 400°C. This lets you print with high-temperature 3D printing materials.

- Add a thermistor that can read up to 500°C. This gives you the right temperature.

- Put cooling fans on stepper motors. This stops them from getting too hot.

Tip: Change your old hotend to an all-metal one before you try high-temperature filament.

Bed and Chamber Needs

Your printer bed and chamber must handle high heat too. A strong bed keeps your print stuck in place. A heated chamber stops warping and helps with chemical resistance. Look at the table below for the best bed temperatures:

|

Material |

Bed Temperature Range (°C) |

|---|---|

|

TPU |

40 - 60 |

|

TPU |

30 |

|

TPU |

50 - 60 |

For advanced materials, use an AC-powered bed. This kind can get up to 230°C. A heated chamber keeps the whole print area warm. You get better layers and fewer failed prints.

Enclosure and Environmental Controls

You need an enclosure for high-temperature jobs. This keeps the heat steady and blocks cold air. Here is why an enclosure is good:

- Keeps heat even, so your print does not warp.

- Stops cold air from cooling your print too fast.

- Lowers the chance of bad sticking and layers coming apart.

- Controls high heat, so you do not get jams or heat creep.

Note: Always check the temperature inside your enclosure. This helps you avoid problems with your 3D printing materials.

A strong printer setup lets you use high temperature filament and advanced materials. You get good prints for hard jobs.

Comparing Heat-Resistant 3D Printing Materials

Heat Resistance and Durability Table

You want to know which 3D printing filaments can take heat and last long. The table below shows how popular materials do with heat, strength, and what they are used for. This helps you choose the best filament for your project.

|

Filament |

Heat Resistance |

Durability |

Applications |

|---|---|---|---|

|

PETG |

Impact and heat resistant |

Durable, flexible |

Mechanical parts, snap-fit enclosures |

|

RYNO |

Superior chemical and heat resistance |

Durable, flexible |

Strong, functional prototypes |

|

ASA |

UV, weather, and temperature resistant |

Strong |

Outdoor clips, planters, fixtures |

|

Nylon |

Tough, shatter resistant |

Strong, flexible |

Living hinges, strong functional parts |

|

ABS |

Wear resistance, heat tolerance |

Strong, ductile |

Interlocking parts, UV and heat exposed parts |

|

PLA |

Stiff but brittle |

Low-stress |

Cosmetic prints, prototypes, desk toys |

|

PET |

Impact and heat resistant |

Durable, flexible |

Mechanical parts, snap-fit enclosures |

|

Tough PLA |

Impact strength close to ABS |

Reliable |

Large volume models |

PETG and ASA are good for outdoor and machine parts. ABS and Nylon make strong prints for moving parts. PLA is best for simple models and toys.

Cost and Ease of Printing

You need to think about price and how easy each filament is to use. Some cost more and need special printers. Others are cheaper and work on most printers. Here is a quick list:

- PLA and Tough PLA: Cheap, easy to use, great for beginners.

- PETG: Costs a bit more, prints easily, works for many things.

- ABS: Costs more, needs a hot bed and cover, good for users with some skill.

- ASA: More expensive, needs a hot bed and cover, best for outside parts.

- Nylon: Costs more, soaks up water, needs drying, strong and bends well.

- Polycarbonate (PC): Expensive, needs high heat, only for advanced users.

- PEEK and Ultem: Very expensive, need special printers, for experts and big jobs.

Tip: If you are new, try PLA or PETG first. Use ABS or ASA when you want stronger, heat-resistant parts.

Common Challenges

You might have problems when printing with heat-resistant materials. The table below shows the most common issues and why they happen.

|

Challenge |

Description |

|---|---|

|

Insufficient Cooling |

Too much heat can change your print’s shape. |

|

Printing Too Hot |

Lowering the heat helps the plastic keep its shape. |

|

Printing Too Fast |

Printing fast does not let layers cool, so they can bend. |

You can fix these problems by changing your printer settings. Slow down your print speed and check your fans. Use the right heat for each filament.

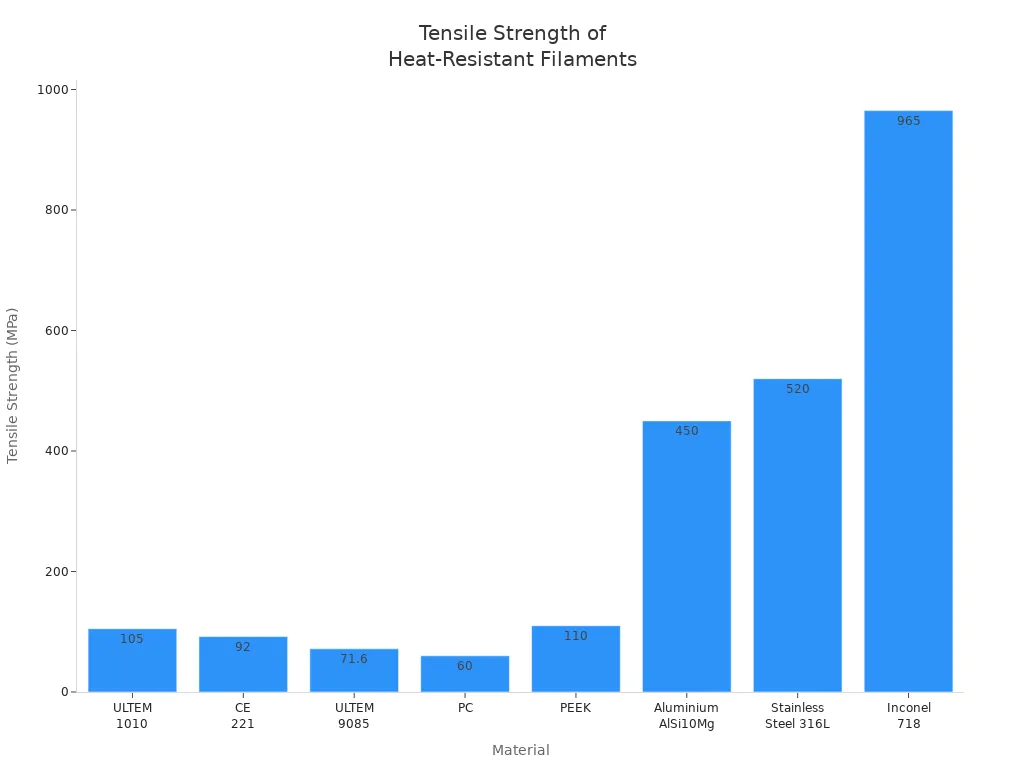

You can choose the best high temperature filament by looking at how each performs and what it costs. The table below shows how ultem, PEEK, and other materials compare in melting point and strength.

|

Material |

Melting Point |

Tensile Strength |

Cost per Unit |

|---|---|---|---|

|

ULTEM 1010 |

340°C |

105 MPa |

€50.03 |

|

PEEK |

343°C |

110 MPa |

€88.42 |

|

PC |

230–260°C |

60 MPa |

€34.45 |

To get started with high-temperature 3D printing, follow these steps:

- Begin with PLA to learn the basics.

- Try advanced materials like PC or PA for stronger parts.

- Use additives and control your print environment for best results.

Tip: Pick your filament based on your project needs and your printer’s abilities.

FAQ

What is high-temperature 3D printing?

High-temperature 3D printing lets you create parts that can handle heat and stress. You use special printers and materials. These parts work in places like cars, airplanes, and factories.

Which filament should I choose for my first high-temperature 3D printing project?

You should start with PET-G. It prints easily and resists heat. PET-G works on most printers. You can move to stronger materials like polycarbonate or ultem when you need more heat resistance.

How do I stop my prints from warping?

You can use a heated bed and an enclosure. Dry your filament before printing. Slow down your print speed. These steps help your parts stick to the bed and keep their shape.

Can I use my regular 3D printer for high-temperature materials?

Most regular printers cannot reach the high temperatures needed for advanced materials. You need a printer with a metal hotend and a heated chamber for best results.

Why do I need to dry my filament before printing?

Moisture in filament causes bubbles and weak spots. Drying your filament keeps your prints strong and smooth. You get better results with high-temperature 3D printing when your material is dry.