Large-format 3D printing lets you create objects much bigger than what standard printers allow. You can make furniture, car parts, or even large art pieces in one go. This type of big 3D printing uses machines with huge build volumes, often several feet wide and tall. People choose large format 3d printing to speed up manufacturing and skip expensive tools. The market for these printers keeps growing:

- The large-format 3D printer market was valued at USD XX Billion in 2024.

- It is projected to reach USD XX Billion by 2033.

- The market is expected to grow at a CAGR of XX% from 2026 to 2033.

You see more industries using 3d technology for rapid, tool-free production.

Key Takeaways

- Large-format 3D printing lets you make big things. You can print furniture and car parts in one piece. This saves time and means less assembly is needed.

- This technology does not need pricey molds or tools. It helps save money for quick testing and custom designs.

- You can pick from many materials, like thermoplastics and composites. This helps match different project needs. It also makes things stronger and tougher.

- Large-format 3D printing is changing many industries. It helps automotive, aerospace, and art fields. It lets people make hard shapes and cuts down on waste.

- You should think about getting a large-format printer. It helps if you want to make bigger parts or try new materials. It can make work faster and give more design choices.

Large-Format 3D Printing Explained

What Is Large-Format 3D Printing?

Some people call large-format 3D printing by another name. They might say large format additive manufacturing. Both names mean the same thing. This process uses big machines to make objects layer by layer. These machines use additive technology. That means you add material instead of cutting it away. This way, you can make very large parts in one piece.

Here is a quick look at other names you might see:

|

Alternative Name |

Description |

|---|---|

|

A way of 3D printing that uses large-format pellet extrusion to make complex shapes. |

Large-format 3D printing is special because it can do jobs regular printers cannot. You can print furniture, car parts, or even big sculptures. This technology lets you skip old steps like making molds or tools.

Build Volume and Scale

The main thing about large-format 3D printing is its huge build volumes. Regular 3D printers have a build area about the size of a loaf of bread. Large-format machines can print things several feet wide, tall, and deep. Some printers have a big build space. You can make items as big as a couch or a car bumper.

You can use these printers to make:

- Full-size furniture pieces

- Large engineering prototypes

- Custom outdoor signs

- Big props for movies or events

This size gives you new ways to design and make things. You do not need to break your project into small parts. You can print the whole thing at once.

Key Differences from Standard 3D Printing

Large-format 3D printing is different from regular 3D printing in many ways:

- Size: You can print much bigger objects with large-format machines.

- Strength: Bigger printers often use stronger materials. Your parts can handle more stress.

- Part Consolidation: You can print one big piece instead of many small ones. This means less assembly.

- Speed and Throughput: Large-format printers can finish big jobs faster. They use bigger nozzles and higher speeds.

Here is a comparison of print speed and batch capacity for different systems:

|

Printer Model |

Print Speed |

Batch Capacity |

|---|---|---|

|

iLux Pro Dental |

Material-dependent |

Up to 12 clear aligners per batch |

|

SprintRay Pro 2 |

8 flat arches in 30 min |

Limited by smaller build platform |

|

Formlabs Form 4B |

100 mm/h |

11 aligner models or 8 splints per batch |

|

UNIZ NBEE |

6 full-arch models in 8 min |

Targets high-volume labs, no direct aligner printing |

Large-format additive manufacturing lets you make more parts at once. You can also make bigger parts in less time.

Main Advantages

You get many benefits when you use large-format 3D printing:

- You do not need expensive molds or tools. Additive manufacturing removes these costs.

- You can quickly make prototypes and custom parts. This helps you develop products faster.

- You save money and time. The process is faster and more efficient than old ways.

- You can create complex shapes that are hard to make with other methods.

Tip: Large-format additive manufacturing helps you bring new products to market faster. You can test ideas and make changes without waiting for new tools.

Large-format 3D printing changes how you make things. You can create large, strong, and complex parts without extra steps. This technology gives you more freedom to design and build what you want.

Technologies in Large Format Additive Manufacturing

FDM, CoreXY, and Industrial Systems

There are a few main technologies in large-format additive manufacturing. Fused Deposition Modeling (FDM) is the most popular. FDM melts plastic and builds objects layer by layer. CoreXY is another system. It moves the print head fast and smooth. Industrial systems use special designs for big jobs. These machines can print things as big as furniture or car parts.

Here is a table that shows the main material types you can use with these systems:

|

Material Type |

Description |

|---|---|

|

Thermoplastics |

Easy to use and recycle. Examples are PLA, ABS, PETG, and TPU. |

|

Composite Filaments |

Plastics mixed with fibers like carbon or glass for more strength. |

|

Metal-filled Filaments |

Plastics mixed with metal powders for a heavy, metal feel. |

|

High-performance Polymers |

Used for tough jobs in cars and planes. |

Hardware Requirements

Large-format printers need strong hardware. You need a sturdy frame and strong motors. Industrial systems use closed-loop motor control. This helps the printer fix mistakes while printing. You also get advanced thermal management. The printer keeps heat even and steady. This helps you print big objects without trouble.

Here is a table comparing industrial and consumer printers:

|

Feature |

Industrial Systems |

Consumer-Grade Printers |

|---|---|---|

|

Motion Control |

Closed-loop for fixing errors |

Open-loop |

|

Thermal Management |

Even heating and insulation |

Basic heating |

|

Material Compatibility |

Many types of materials |

Fewer options |

Industrial systems let you print bigger objects. You can use more materials and get better results.

Material Options

You have lots of choices for materials in additive manufacturing. Thermoplastics are popular because they are easy to use. Composite filaments make prints stronger for tough jobs. Metal-filled filaments give prints a real metal look and feel. High-performance polymers work well in cars and planes. You can pick the best material for your project.

Large-Scale Metal Additive Manufacturing

Large-scale metal additive manufacturing is changing how you make big metal parts. It lets you build large metal pieces without cutting or shaping by hand. You can use processes like directed energy deposition. This melts metal powder or wire to make each layer. Large-format metal additive systems have big build spaces. You can make whole parts in one piece.

Here is a table with the latest advancements:

|

Advancement |

Description |

Impact on Industries |

|---|---|---|

|

Big Metal Additive Manufacturing |

Builds large metal parts additively, no need for machining. |

Faster production, less waste in aerospace and energy. |

|

Directed Energy Deposition (DED) |

Melts metal powder or wire layer by layer. |

Makes and repairs large parts, saves money. |

|

Large Build Envelopes |

Prints big, complex parts with high accuracy. |

Makes whole parts at once, less post-work. |

You can see big metal additive manufacturing in aerospace, energy, and defense. It gives faster production, less waste, and stronger parts.

Applications of Large-Format 3D Printing

Large-format 3D printing helps many industries make new things. You can use it for quick prototypes, building parts, and construction 3d printer projects. Here are the main uses and why large-format 3d printing works well for each.

Home and Furniture

Large-format 3d printing lets you make custom furniture and home decorations. You can print chairs, tables, shelves, and lights. Big printers can make full-size pieces at once. You do not need to put together lots of small parts. This saves time and makes things stronger.

- Why it’s ideal: You can design shapes and sizes that fit your room.

- Benefits of single-piece printing: There are fewer weak spots and a smoother look.

- Recommended materials: PLA, PETG, and composite filaments are strong and last long.

- Variations: You can print parts that fit together or big items ready to use.

Cosplay and Props

Large-format 3d printing changed how people make cosplay props and costumes. You can print helmets, armor, and weapons in full size. You do not have to split designs into small pieces.

|

Benefit |

Description |

|---|---|

|

Size |

Large-format printers make full-size props without splitting designs. |

|

Customization |

Big build spaces let you make detailed designs and bright colors for cosplay. |

|

Efficiency |

Artists can make large, colorful art or themed decorations fast, saving time and supplies. |

- Why it’s ideal: You can make real, life-size copies.

- Benefits of single-piece printing: Props have no seams or weak spots, so they last longer.

- Recommended materials: PLA is easy to paint, ABS is strong, and TPU bends for flexible parts.

- Variations: You can print props in pieces for travel or as one big display.

Prototyping and Engineering

Prototyping is a top use for large-format 3d printing. You can turn computer designs into real models fast. This helps you test ideas and change them before making the final product.

- Why it’s ideal: You can make big engineering models in days, not weeks.

- Benefits of single-piece printing: You skip assembly mistakes and see the real size.

- Recommended materials: PLA is good for quick models, PETG is tough, and metal-filled filaments add weight and look real.

- Variations: You can print full-size models or small ones for showing ideas.

Tip: Large-format additive manufacturing makes prototyping faster and helps you launch products sooner.

Art and Sculpture

Artists use large-format 3d printing to make sculptures with cool designs. You can print detailed lattice shapes, smooth curves, and pieces that look like they float.

- Artists make sculptures that seem to break the rules of gravity.

- Lattice shapes and smooth curves show how exact 3D printing can be.

- Studios like Nervous System and Joshua Harker mix art and math, making digital art you can touch.

- Some sculptures are so thin and detailed that only 3D printing can make them, showing what this tech can do.

- Why it’s ideal: You can make hard shapes that old methods cannot.

- Benefits of single-piece printing: You get smooth, detailed art with no need to put pieces together.

- Recommended materials: PLA is easy to finish, resin shows details, and metal-filled filaments look special.

- Variations: You can print big art for shows or small, detailed pieces.

Automotive and Mechanical Parts

Large-format 3d printing is used in car making and engineering. You can print light body panels, custom inside trims, and test parts.

|

Application Type |

Description |

|---|---|

|

Used to make parts that make cars lighter and save fuel. |

|

|

Custom Interior Trims |

Lets you make special designs for each customer. |

|

Prototype Components |

Helps you test parts with tricky shapes and change designs fast. |

- Why it’s ideal: You can test and make parts quickly, saving money and time.

- Benefits of single-piece printing: You skip extra steps and make stronger parts.

- Recommended materials: High-performance polymers, composite filaments, and metal work for tough jobs.

- Variations: You can print big panels or small parts for testing.

Architecture and Education

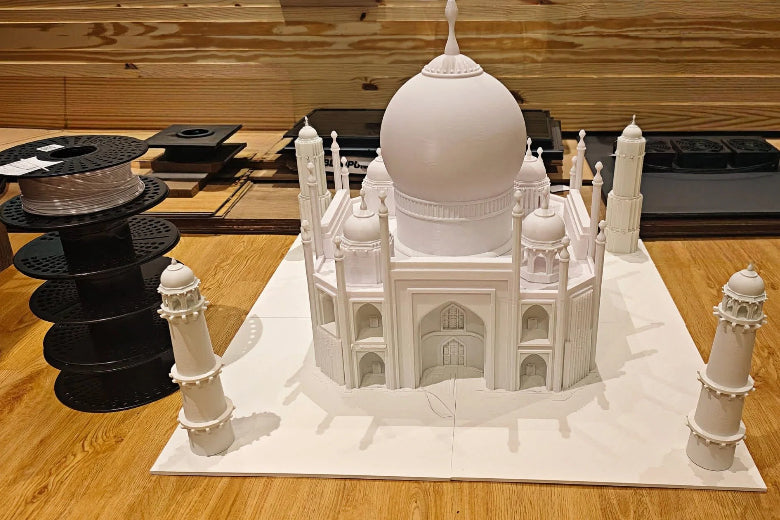

Large-format 3d printing helps architects and students turn computer designs into real models. You can print columns, arches, and detailed rooms to show your ideas.

- Architects and engineers use 3D printing to make real models from computer designs.

- You can print columns, arches, and fancy rooms to show off your work.

- This tech makes model building faster, cheaper, and easier for showing ideas to clients.

- Resin, PLA, and composites help make models that look and feel like real buildings.

- Students learn by making real models, which helps them understand design and building better.

- Why it’s ideal: You can make exact, detailed models for showing and learning.

- Benefits of single-piece printing: Models are strong and smooth, easy to use.

- Recommended materials: PLA for models, resin for details, and concrete for big building parts.

- Variations: You can print small models or big building features.

Outdoor and Garden Objects

Large-format 3d printing lets you make outdoor furniture, planters, and garden art. You can use materials that last outside for a long time.

- Why it’s ideal: You can make shapes and sizes that fit your yard.

- Benefits of single-piece printing: You get strong, tough objects with no weak spots.

- Recommended materials: PETG, ABS, and composite filaments last outside.

- Variations: You can print sets that fit together or big, single sculptures.

Large Functional Prints

Large-format 3d printing helps you make working things that were not possible before. You can print tools for healthcare, jet engine parts, and even food.

- Healthcare: 3D printing makes tools and even small human hearts, like BioLife4D did with stem cells.

- Aeronautics: GE Aviation uses 3D printing to make jet fuel nozzles for their LEAP engine as one piece, making building easier.

- Food: 3D printing is used to make fancy food designs, like desserts and seafood, showing how flexible this tech is.

- Why it’s ideal: You can make tricky, working parts in one step.

- Benefits of single-piece printing: You skip assembly and make parts more reliable.

- Recommended materials: Metal is strong, high-performance polymers last long, and food-safe materials work for cooking.

- Variations: You can print test models, finished parts, or even food.

Note: Large-format 3d printing brings additive manufacturing to new areas and lets you try new uses that were not possible before.

Technical Tips for Large-Format Printing

Frame and Motion Systems

When you use large-format 3D printing, you need a strong frame and a smooth motion system. A rigid frame keeps your big 3D printers steady. This reduces shake and helps you get clean prints. Many large build volume 3D printing machines use the CoreXY motion system. This design lets the print head move fast and smooth, even when the bed stays still. Linear rails add more stability and make each layer accurate. Advanced firmware and real-time feedback sensors help control movement and fix small errors as you print.

- Choose a frame that does not flex.

- Look for linear rails for smooth movement.

- Use printers with smart firmware for better results.

Nozzle and Hotend Choices

Picking the right nozzle and hotend is key for large-scale printing applications. You want to move a lot of material fast, especially for big parts or metal prints. Here is a quick guide:

|

Nozzle Type |

Key Features |

Best For |

|---|---|---|

|

High-flow nozzles |

Fast filament movement, bigger melt zone |

Large parts, thick layers, metal |

|

Copper nozzles |

Great heat transfer, handles high temperatures |

High-temp and sticky materials, metal |

|

Two-piece nozzles |

Combines heat efficiency and wear resistance |

Abrasive filaments, carbon fiber, metal |

High-flow nozzles work well with thick layers and metal. Copper nozzles are best for sticky materials like PETG or metal. Two-piece nozzles last longer with abrasive filaments, including metal-filled ones.

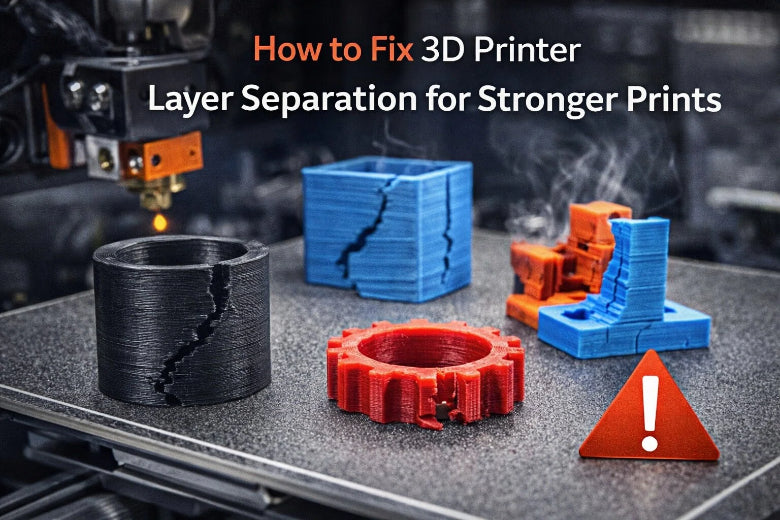

Bed Adhesion and Warp Control

Large-format 3D printing often means big parts that can warp or lift. You need the right bed surface for your filament. Clean your bed with isopropyl alcohol before each print. Slow down your first layer to 20–30 mm/s. Use brims or rafts for extra grip. For metal prints, make sure the bed stays hot and use adhesives if needed.

|

Filament Type |

Best Surfaces |

Tips |

|---|---|---|

|

PLA |

Blue tape, PEI, glass |

Glue stick on glass, sand for grip |

|

ABS |

Kapton, heated glass |

Bed at 90–110°C, use enclosure |

|

PETG |

PEI, glue stick on glass |

Lower bed temp after first layers |

|

TPU |

PEI, glass, magnetic |

Lower bed temp, use release agent |

|

Metal |

PEI, heated glass |

Keep bed hot, use special adhesives |

- Match your bed to your filament.

- Use adhesives for tricky materials.

- Keep the print area warm to stop warping.

Slicing Strategies

Good slicing makes large-format 3D printing faster and better. Adjust your layer height for speed or detail. For drafts, use 0.28–0.32mm. For a balance, try 0.24mm. Standard prints use 0.2mm. Pick fast infill patterns like lines or rectilinear. Avoid slow patterns like gyroid. Use tree supports to save time and material. Rotate your part to use fewer supports.

Tip: For large metal prints, use thicker layers and simple infill to finish faster.

You can get great results from your big 3D printers by following these tips.

Choosing a Large-Format 3D Printer

Key Specifications

When you want a large-format 3D printer, look at some important features. Big 3D printers come in different sizes. Some can print things as big as 10 feet by 40 feet. You need a strong frame and a good control system. Dual gantries let you print and trim at the same time. Some advanced printers can print tall or angled parts. This is because they have special layer systems. A steel frame keeps the printer steady. Fume extraction helps keep your work area safe. The extrusion system should work with many materials. It should handle high-temperature thermoplastic composites and metal.

|

Specification Type |

Details |

|---|---|

|

Available Sizes |

10'x10', 10'x20', 10'x40', 15'x20', 15'x40' |

|

Gantry & Control System |

Dual gantries and dual controls for simultaneous printing and trimming |

|

Advanced Capabilities |

Vertical Layer Print System for tall parts and Angle Layer Print System for angled parts |

|

Core Technology |

Uses advanced Ultra 6 control and a rigid structural steel gantry with fume extraction |

|

Material Processing |

Capable of processing various thermoplastic composite materials, including high-temperature ones and metal |

Tip: Pick a printer that fits your project size and the materials you want to use. If you want to print metal, make sure your printer can handle high heat.

Who Needs Large-Format Printing

Large-format 3D printing helps many people and businesses. You might need a big printer if you work in life sciences or at a school. Life sciences use these printers for flexible designs and to save money. Schools and labs use them for research in materials and making things.

|

Industry/Profession |

Benefits of Large-Format 3D Printing |

|---|---|

|

Life Sciences |

Improved flexibility, reduced costs, accelerated R&D |

|

Academic Institutions |

Advanced research in materials and manufacturing |

You also need a big printer for large jobs in cars, planes, and making metal parts.

When to Upgrade

You should get a large-format 3D printer when your old one is too small. If you want to print metal parts, big furniture, or prototypes in one piece, it is time to upgrade. You save time and money by printing big things without splitting them. You also get stronger parts with fewer seams. If your business gets bigger or you want to try new materials like metal, upgrading is a good idea.

Note: Upgrading lets you try new designs and big projects. You can print metal parts, large art, or custom tools easily.

You now know that large-format 3D printing uses big machines to make large things fast. This technology helps people come up with new ideas for making stuff. It also lets you build strong and special parts. You can try easy projects first, like a garden bench, a big planter, or a sign you design yourself. Give your first big print a try and see how simple it is to make something cool. Large-format 3D printing will get even better soon because new tools and materials are on the way.

-

Starter project ideas:

- Outdoor bench

- Oversized wall art

- Custom storage box

FAQ

What makes large-format 3D printing different from regular 3D printing?

Large-format 3D printing uses big 3D printers with much larger build volumes. You can print full-size furniture, car parts, or art in one piece. This saves time and makes stronger objects.

Can I use large-format 3D printing at home?

Yes, you can use large-format 3D printers at home. Many hobbyists print large storage boxes, garden planters, or cosplay props. Make sure you have enough space and a sturdy table for your printer.

What materials work best for large build volume 3D printing?

You can use PLA, PETG, and ABS for most projects. For outdoor or strong parts, try composite filaments or high-performance polymers. Always check your printer’s material compatibility before starting.

How do I prevent warping in large-scale printing applications?

To stop warping, use a heated bed and keep your print area warm. Clean the bed before printing. Add a brim or raft for better grip. Slow down the first layer for best results.