PETG filament stands out as your top pick in 2025 for making both molds and daily essentials. Makers like you value its unique mix of durability, easy printing, resistance to moisture, and low emissions. Take a look at what sets it apart:

|

Reason |

Explanation |

|---|---|

|

Durability and Strength |

Tough, flexible, and less likely to break under stress. Ideal for molds and functional parts. |

|

Easy Printing and Minimal Warping |

Reliable prints with excellent bed adhesion and low warping. |

|

Moisture Resistance |

Handles humidity and water exposure, perfect for daily use. |

|

Odorless and Low Fume Emissions |

Safer and more comfortable for indoor projects. |

|

Excellent Transparency and Finish |

Delivers a smooth, glossy look for professional results. |

You find PETG filament in water bottles, medical devices, and food packaging thanks to its strength and clarity. Its cost fits right between budget and specialty filaments, so you get quality and value.

Key Takeaways

- PETG filament offers strong, flexible, and durable prints that resist breaking and hold their shape well, making it ideal for molds and daily use items.

- Printing with PETG is easy due to its low warping, strong layer adhesion, and good precision, which helps you create reliable and accurate parts.

- PETG resists moisture, many chemicals, UV light, and heat, so your prints last longer indoors and outdoors without losing strength or color.

- PETG is safe for food contact when using FDA-approved filament and proper printing methods, and it emits very low fumes, making it great for home or classroom use.

- You can achieve clear, glossy, and professional-looking prints with PETG, plus enjoy a wide range of colors to match your project’s style.

PETG Filament Strength

Toughness

You want your molds and daily essentials to last. PETG filament gives you that reliability. The glycol modification in PETG makes it tougher than standard PET. This change improves both layer adhesion and overall mechanical strength. When you print with PETG filament, you get parts that resist breaking and hold up under stress. Laboratory tests show that PETG maintains its strength even after remelting, which means your molds stay strong and functional. Dimensional stability tests also reveal that PETG parts deform less than 1% under pressure, so you can trust your prints to keep their shape.

Flexibility

Flexibility matters when you need parts that bend without snapping. PETG filament offers a unique balance between strength and flexibility. Unlike PLA, which is strong but brittle, PETG bends and flexes before it breaks. This property helps your molds and daily items survive drops or pressure. The glycol in PETG not only boosts toughness but also allows for better interlayer bonding. You get prints that are less likely to crack or split, even with repeated use.

Impact Resistance

Impact resistance sets PETG filament apart from many other materials. You can see the difference when you compare it to ABS and PLA:

|

Material |

Tensile Strength (MPa) |

Impact Resistance |

|---|---|---|

|

PLA |

50-60 |

Brittle, low resistance |

|

PETG |

40-50 |

Superior, flexible |

|

ABS |

34-36 |

Tough, more rigid |

PETG filament stands out with higher tensile strength than ABS and better impact resistance than both ABS and PLA. This means your parts can handle bumps, drops, and daily wear without breaking. For mold making, this durability ensures your tools last longer and perform better.

Printability

Minimal Warping

You want your prints to stay flat and true to their design. PETG filament helps you achieve this goal. Its excellent thermal properties allow it to cool efficiently, which means you see almost no warping during the printing process. The material sticks well to the print bed, so your parts do not lift or curl at the edges. For larger prints, you can turn off the part cooling fan for the first few layers to further reduce the risk of warping. This makes PETG a reliable choice for both small and large projects.

Layer Adhesion

Strong layer adhesion gives your prints better strength and durability. PETG filament bonds each layer tightly, so your finished parts resist splitting or cracking. You do not need special adhesives or complex setups. A simple glue stick or blue painter’s tape on the print bed works well. This ease of use means you spend less time troubleshooting and more time creating. Beginners appreciate the forgiving nature of PETG, while experienced makers enjoy the consistent results.

Precision

You can achieve impressive accuracy with PETG filament. The material balances easy printing with stable dimensions, making it ideal for functional parts that need to fit together. Several factors help you reach high precision:

- Material properties like low thermal expansion and good viscosity support tight tolerances.

- Proper printer calibration, including bed leveling and extruder adjustment, ensures accurate prints.

- Print settings such as layer height, nozzle size, and temperature control affect detail and resolution.

- Environmental stability, like keeping humidity between 30-50%, helps maintain accuracy.

Tip: Use a smaller nozzle (0.2-0.4mm) for detailed prints, and store your filament in a dry place to prevent moisture issues.

PETG filament works well with most FDM 3D printers. You find it easy to use, whether you are just starting or have years of experience. Its low warping, strong adhesion, and reliable precision make it a favorite among makers of all skill levels.

Resistance

Chemical

You need materials that can handle exposure to different chemicals, especially for molds and daily essentials. PETG filament stands out because it resists many common chemicals, including acids, bases, and alcohols. This property makes it a smart choice for items that come into contact with cleaning agents or food. You can wash PETG prints with soap and water without worrying about damage. Many makers use PETG for containers, kitchen tools, and laboratory parts because it does not absorb moisture or break down easily.

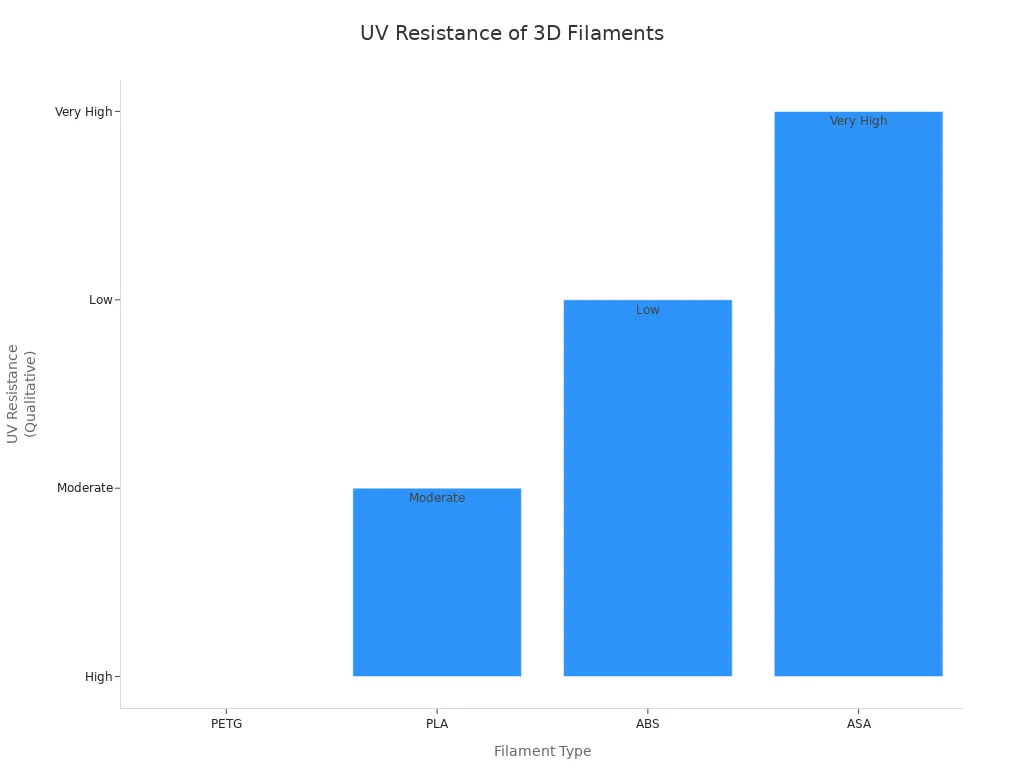

UV

If you plan to use your prints outdoors or in direct sunlight, UV resistance becomes important. PETG filament performs well under prolonged UV exposure. It keeps its strength and color longer than PLA or ABS. You can see how PETG compares to other popular filaments in the table below:

|

Filament |

UV Resistance |

Heat Resistance (HDT/Tg) |

Notes |

|---|---|---|---|

|

PETG |

High UV resistance, suitable for outdoor use and direct sunlight exposure |

HDT ~70ºC, Tg ~77ºC |

Superior strength, durability, and chemical resistance compared to PLA; 100% recyclable |

|

PLA |

Considerably UV resistant but lower heat resistance (Tg ~57ºC) |

Tg ~57ºC |

May degrade under increased temperature and humidity; suitable for light outdoor use but not structural parts |

|

ABS |

Raw ABS has poor UV resistance; additives improve UV resistance |

N/A |

Widely used but less UV resistant than PETG; UV resistance depends on additives |

|

ASA |

Most UV resistant filament; about 10x more UV and weather resistant than ABS |

N/A |

Best choice for outdoor and direct sunlight applications; superior mechanical properties and aesthetics |

You can trust PETG for garden tools, outdoor fixtures, and sun-exposed parts. It will not yellow or become brittle quickly.

Heat

Heat resistance matters for items that face warm environments or hot water. PETG filament has a heat deflection temperature around 70°C and a glass transition temperature near 77°C. This means your prints will not deform easily in most household or outdoor conditions. You can use PETG for dishwasher-safe items, car parts, or electronics enclosures. For very high heat, you might choose a specialty filament, but PETG covers most daily needs.

Tip: If you need a filament for both outdoor and indoor use, PETG offers a great balance of chemical, UV, and heat resistance.

Safety

Food Safe

You want to create food containers, utensils, or kitchen tools that are safe for daily use. PETG filament gives you this option when you choose the right product and follow best practices. Manufacturers often test their PETG filaments in labs and ensure they meet FDA regulations. These tests confirm that the material does not contain harmful additives or dyes. Some companies also work with notified bodies, which are government-approved organizations that check for compliance with food safety standards. You should look for PETG filament labeled as FDA-approved and made in clean facilities. For extra safety, use a food-grade stainless steel nozzle during printing. Applying a food-safe coating, such as epoxy or silicone, can seal the surface and prevent bacteria from growing in tiny pores. Remember, these coatings wear down over time, so avoid using printed items for long-term food storage.

Tip: Always check the manufacturer’s certification before using any filament for food contact projects.

Low Emissions

You care about the air quality in your workspace. PETG filament helps you maintain a safer environment. Scientific studies show that PETG emits very low levels of volatile organic compounds (VOCs) and ultrafine particles during printing. Most emissions occur at the start of the print, but the levels stay much lower than those from ABS or nylon. When you print at standard temperatures (220–270 °C), PETG does not break down or release significant fumes. The main VOC detected is acetaldehyde, but its concentration remains low. This makes PETG a smart choice for home or classroom use, especially if you have limited ventilation.

Recyclable

You want to reduce waste and support eco-friendly production. PETG filament is recyclable, but it requires special handling. Most municipal recycling programs do not accept it because of its glycol modification. Specialized facilities or companies can recycle PETG, but you need to check local options. The table below compares PETG with other common filaments:

|

Aspect |

PETG Filament |

PET Filament (PET) |

PLA Filament |

|---|---|---|---|

|

Recyclability |

Recyclable but more challenging |

Widely recyclable |

Generally recyclable |

|

Recycling Code |

Code 7 (Other) |

Code 1 |

N/A (bioplastic, varies) |

|

Recycling Acceptance |

Limited acceptance in municipal programs |

Widely accepted in recycling centers |

Widely accepted in composting/recycling |

|

Melting/Recycling Behavior |

Glycol modification prevents clean melting, fouling machines |

Melts cleanly, easy to recycle |

Biodegradable, compostable |

|

Practical Recycling Options |

Requires specialized facilities or companies |

Accepted by most municipal recycling centers |

Accepted by many composting programs |

|

Environmental Impact |

Recycling reduces landfill waste but may degrade material properties |

Recycling reduces landfill waste and conserves resources |

Composting reduces landfill waste |

You help the environment by choosing PETG filament for projects that last. Recycling PETG reduces landfill waste, but always check if your local recycling center accepts it.

Aesthetics

Transparency

You can achieve impressive clarity with PETG. This material offers excellent optical transparency, making it a strong choice for projects that need to look clear and professional. You often see it used in clear packaging, cosmetic containers, and display cases. PETG lets light pass through with minimal haze, so your prints look clean and sharp. While polycarbonate provides the highest level of transparency—almost like glass—PETG comes very close and even outperforms acrylic in clarity for many uses. If you want a part that looks almost see-through, PETG gives you that option without sacrificing strength.

Smooth Finish

You want your prints to look polished and professional. PETG naturally produces a glossy surface, which helps your projects stand out. You can make the finish even smoother by using a few simple techniques:

- Start sanding with coarse sandpaper to remove layer lines, then move to finer grits for a silky feel.

- Apply a self-leveling epoxy resin, such as XTC-3D, to fill in tiny gaps and create a glass-like shine.

- Try wet sanding with high-grit sandpaper to reduce heat and avoid deformation.

- Use a heat gun at a safe distance to seal the outer layer and smooth out imperfections.

Tip: Practice these finishing steps on a test print first to get the best results.

These methods help you minimize visible lines and give your prints a professional look. PETG stands out because it balances durability with a naturally glossy appearance, so your finished parts look less like typical 3D prints and more like real products.

Color Options

You have a wide range of color choices with PETG. Manufacturers offer everything from crystal-clear to vibrant solid colors. You can pick transparent, translucent, or opaque shades to match your project’s needs. This variety lets you create eye-catching models, functional parts, or even artistic pieces. PETG’s glossy finish enhances each color, giving your prints a professional and attractive appearance. Whether you want a subtle look or something bold, you can find a PETG color that fits your vision.

You see more makers and semi-professionals choosing PETG filament for good reasons. This material gives you strong, reliable prints with great impact resistance and heat tolerance. You enjoy easy printing and a smooth finish. Many industries and schools now use PETG filament because it works well with most 3D printers and offers many color options.

- Makers value its durability and safety.

- Teachers use it in STEM classes.

- Manufacturers create new blends to meet your needs.

Try PETG filament for your next project and experience its growing popularity firsthand.

FAQ

What printer settings work best for PETG filament?

You should print PETG at 220–250°C with a heated bed set to 70–80°C. Lower your print speed to 40–60 mm/s for better results. Use minimal cooling for the first layers. Adjust retraction settings to reduce stringing.

Can you use PETG for food-safe projects?

Yes, you can use PETG for food-safe items if you choose FDA-approved filament and print with a clean, stainless steel nozzle. Always apply a food-safe coating to seal the surface. Avoid using PETG prints for long-term food storage.

How do you store PETG filament?

Store PETG filament in a dry, airtight container. Use silica gel packs to keep moisture away. Moisture can cause poor print quality and bubbles. Always reseal the spool after use.

Does PETG filament require special post-processing?

You can sand, polish, or coat PETG prints for a smoother finish. Wet sanding works well. Use a heat gun carefully to seal the surface. PETG does not respond to acetone smoothing like ABS.