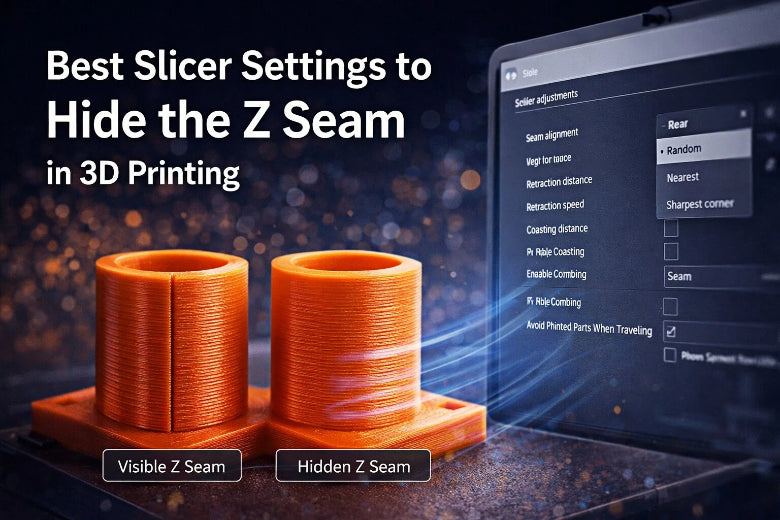

Best Slicer Settings to Hide the Z Seam in 3D Printing

Optimize z seam placement in your slicer to hide seams and minimize blobs for smoother 3D prints with professional surface quality.

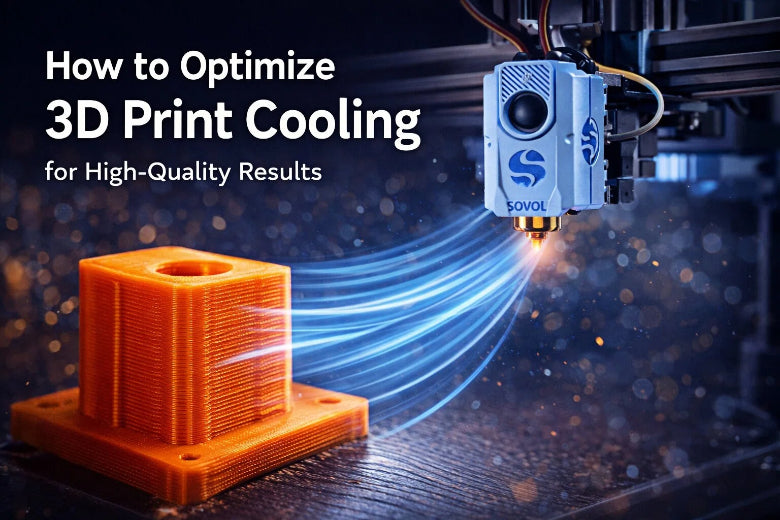

How to Optimize 3D Print Cooling for High-Quality Results

Improve print quality with the right 3D print cooling strategy. Adjust fan speed, placement, and slicer settings for smoother, stronger 3D prints.

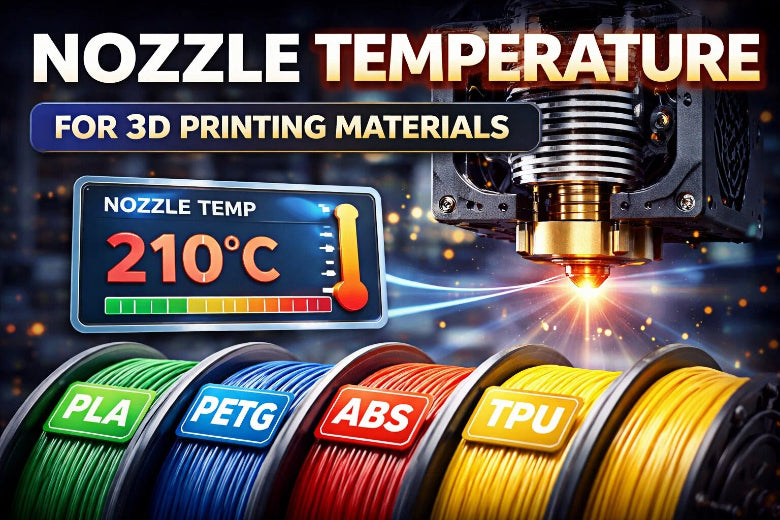

The Ultimate Guide to Nozzle Temperature for 3D Printing Materials in 2026

3D print nozzle temperature guide for 2026: Find optimal settings for PLA, ABS, PETG, and more to boost print quality and prevent common printing issues.

How Many Top Layers Should You Use in 3D Printing for Smooth Results

Use 3 to 5 3D print top layers for smooth, strong surfaces. Adjust layer height and infill for best results and avoid gaps or rough finishes.

When Should You Upgrade Your 3D Printer Instead of Changing Settings?

Decide when to fix vs upgrade 3d printer: If settings don't solve print issues, hardware limits may mean it's time for an upgrade or replacement.

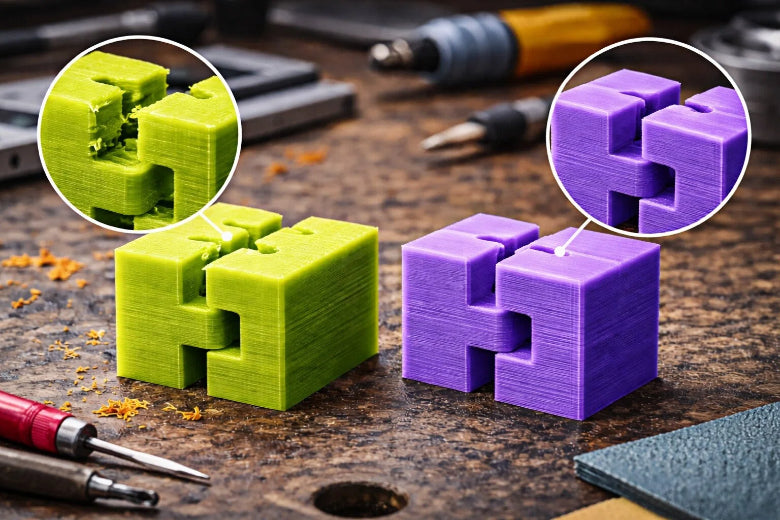

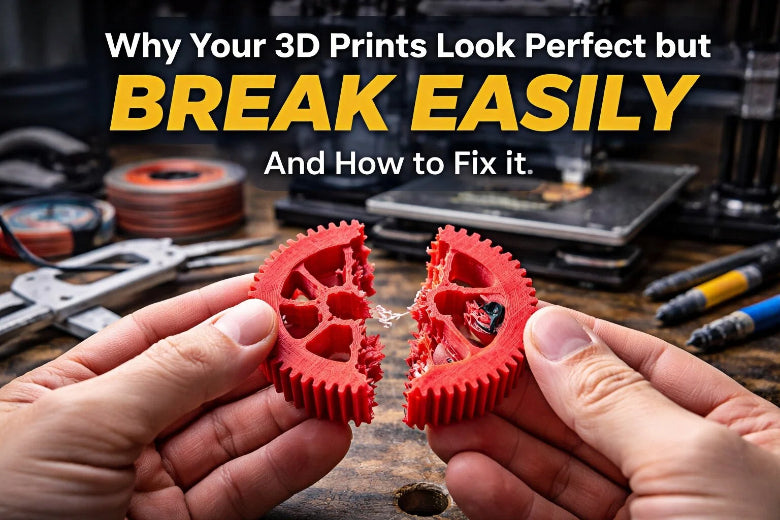

Why Your 3D Prints Look Perfect but Break Easily (And How to Fix It)

3D prints can look perfect but break easily due to weak layer bonding or infill. Boost 3D Print strength with better settings, quality filament, and smart design.

How to Fix Common Print Defects by Adjusting Printer Settings

Find out what affects 3D print quality most and how adjusting printer settings can fix defects like warping, stringing, and poor bed adhesion.

Why Filament Type Matters for Consistent 3D Print Quality

Filament affects print quality by influencing strength, surface finish, and reliability. See why type and brand matter for consistent 3D printing results.

How to Choose the Right 3D Printing Build Plate for Your Needs

Choose the right 3D Printing Build Plate by matching your filament and workflow needs for better adhesion, easy removal, and improved print quality.

How to Choose the Right 3D Printer Nozzle Size for Your Project

Choose the best 3D Printer Nozzles size for your project by balancing detail, speed, strength, and material compatibility for optimal results.

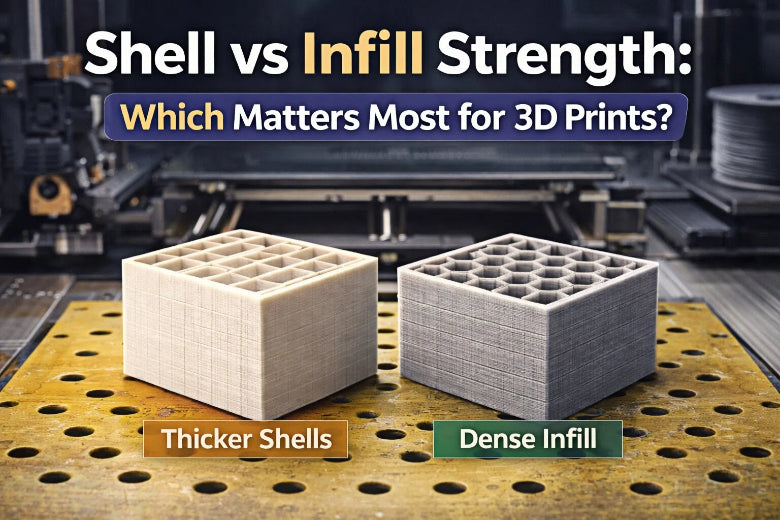

Shell vs Infill Strength Which Matters Most for 3D Print?

Shell thickness impacts 3D print strength more than infill density. For best results, balance shell vs infill strength based on your part’s needs.

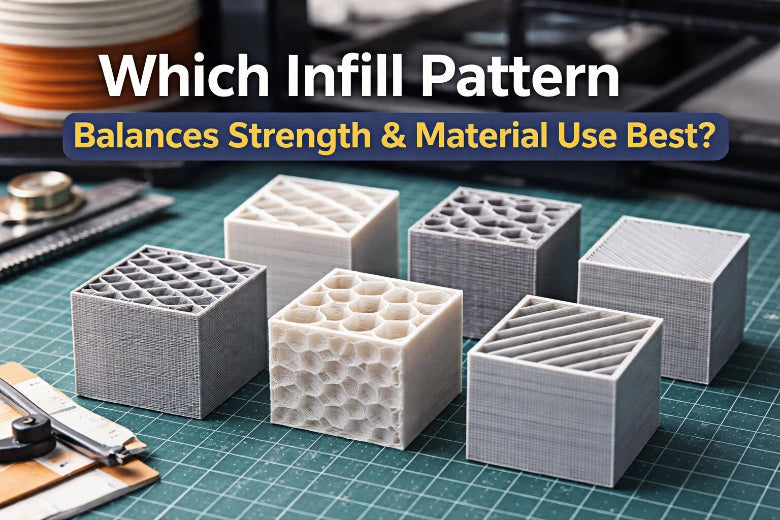

Which Infill Pattern Balances Strength and Material Use Best

Infill patterns explained: Gyroid infill offers the best balance of strength and material use for 3D prints, making it ideal for most functional projects.